COMPANY Insight

Mining companies often have hauling needs which exceed the capabilities of common commercial trailers in size or weight but do not rise to the level where a mining truck and trailer (200+ tonnes) would be required. It is the design and manufacture of this type of trailer that sets Rogers Brothers Corporation apart from others in the trailer industry.

Mid-Size Trailers for the Open Pit Mining Industry

Scroll down to read the article

Who is Rogers Brothers Corporation?

ROGERS is an industry leading manufacturer of heavy-duty trailers located in Albion, Pennsylvania, USA. Founded in 1905, the company is presently in its fourth generation of continuous family ownership and operation. Throughout our long history, we have built trailers for customers in all fifty states in the USA and in 65 countries all over the world.

What types of trailers does ROGERS manufacture?

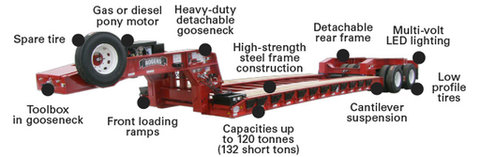

The most common use for our trailers is the hauling of machinery in and around the mine. We offer two types of trailers to meet this purpose: fixed gooseneck trailers and hydraulic detachable gooseneck trailers. Either type can be custom designed to meet the customer’s specification for capacity, length, or width. ROGERS can design and build either style trailer in capacities up to 120+ tonnes, deck lengths up to 48 feet (14.6 meters) and widths up to 186 inches (4.7 meters).

What are the positives and negatives of fixed gooseneck models?

Fixed gooseneck trailers by ROGERS feature a simple yet durable design to provide many years of reliable service. Machines are loaded and unloaded over the rear of the trailer, often with the use of hydraulically operated ramps.

PROS:

- Quick and easy operation

- Additional load space over the wheel area of the deck

- More ground clearance than detachable gooseneck models

- Lighter weight design due to deeper main carrying beams

CONS:

- Higher deck height than detachable gooseneck models

- Steeper load angle for machinery to climb on to the trailer deck

What are the advantages and disadvantages of detachable gooseneck models?

The primary advantage of the ROGERS detachable gooseneck trailers is that they provide a low deck height for hauling tall machinery or payloads where overhead clearance restrictions exist. The gooseneck detaches from the trailer frame with the use of powerful hydraulic cylinders. Once detached, the tractor and gooseneck are driven away from the trailer and machinery can then be loaded or unloaded over the front of the deck.

PROS:

- Low deck height optimizes overhead clearance for tall machines or payloads

- Lower approach angle makes loading and unloading of machines safer and easier

- More balanced weight distribution between trailer axles and kingpin load to tractor

- Detachable gooseneck trailers for open pit mines are also detachable at the rear of the deck allowing the use of deck extensions or other style deck constructions (drop sides or beam deck)

CONS:

- Requires a hydraulic power source to operate the gooseneck – either tractor PTO or gasoline/diesel pony motor on the trailer

- Lower ground clearance than fixed gooseneck models

- Requires more operating space to load and unload machinery

Fixed gooseneck trailers by ROGERS feature a simple yet durable design to provide many years of reliable service.

Communication is always the key to the successful design of a ROGERS custom trailer

How does the specification and ordering process work?

A great place to start is to visit the mining industry page on our company website. Each trailer on that page was custom-designed and build for a customer and has detailed specifications including photographs and dimensional drawings.

In some cases, one of these existing models will meet a customer’s requirements. In other cases, one may serve as a good “starting point” for the development of a custom trailer for the customer.

Communication is always the key to the successful design of a ROGERS custom trailer. There are a number of important details that must not be overlooked in this process, including:

- Detailed information on the tractor, or towing vehicle, is necessary to ensure the correct compatibility between tractor and trailer. The ROGERS sales technician will inquire about dimensions, towing capacity, electrical and hydraulic specifications of the customer’s tractor

- If the customer is purchasing the trailer to haul a specific machine (a large bulldozer, for example) we will gather information on the machine and prepare a dimensional drawing of the proposed trailer showing the loaded machine and the resulting dimensions and weight distribution

There are other key elements to the successful design of a custom trailer including the operating environment (i.e. road conditions, hazards, etc.) and regulatory requirements which may impact the trailer (i.e. lighting or braking requirements, dimensional limitations).

You can play a really important role in the mining lifecycle by getting this stuff right early on

What sets ROGERS apart from the competition?

For over a century, Rogers Brothers Corporation has designed and supplied superior trailers to our customers. Combining our experience with our willingness to embrace new technologies, materials, and designs gives ROGERS a significant advantage in the trailer industry. It is this advantage which allows us to give our customers what they most require from their trailer investment – VALUE!

Contact Information

Website: www.rogerstrailers.com

Contact Rogers via their online form

Toll Free (USA): 1-800-441-9880

Phone: +1 814-756-4121

Fax: +1 814-756-4830