Contact us for more information or to book a demo today.

+61 427 127 544 | sales@mintap.com.au | mintap.com.au

Because you can’t manage what you don’t measure

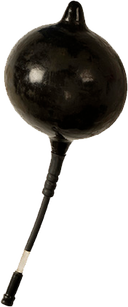

The C-Gap provides a safe and environmentally friendly alternative for measuring the Closed Side Setting (CSS) in Cone, Jaw, and Gyratory Crushers.

Accurate to within 1mm and able to measure CSS’s between 6mm and 250mm, the C-Gap enables Operators and Maintenance Staff to measure the CSS for most sized crusher installations in minutes with a simple and robust hand held solution.

Operations are managed via the lightweight, handheld console. The battery-powered device is both splashproof and dustproof for continued use at mine sites, and can be calibrated using lead weights or manual measurement for optimum accuracy.

The C-Gap effectively replaces the need to use lead weights on a continual basis or any other rudimentary methods such as aluminium foil balls, clay, 44 gal drums or used oil filters.

Operators and maintenance personnel stand in a safe position above the entry to the crusher passing the bulb down through the crusher chute to the nip point for the measurement. There is no longer the need to send personnel under the crusher to manually measure the CSS.

C-Gap reduces the need to use lead weights when processing ore, and is so simple that it only requires one worker to operate it.

Designed and manufactured in Germany in collaboration with Mintap, the C-Gap has been embraced by leading mining and quarrying operations throughout the world, including USA, Canada, Chile, Zambia, The Philippines, Norway, Russia and Australia"

C-Gap is certified according to AS/NZS CISPR 22: 2009.

Mintap delivers innovative technologies that improve operations in the mining and quarrying industries.