SCT Operations - Strata Control Technology

Two Decades of Experience Using

Hydraulic Fracturing

for Preconditioning and Cave Inducement

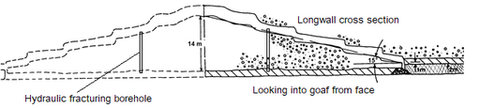

SCT Operations Pty Ltd (SCT) has been applying hydraulic fracturing to improve mining conditions since 1999 when hydraulic fracturing was used at Moonee Colliery in NSW Australia to manage windblast events associated with delayed caving of the strong conglomerate roof above a longwall panel. The strategy was immediately successful thanks to an intensive characterisation study. The mine continued to operate successfully without further incident.

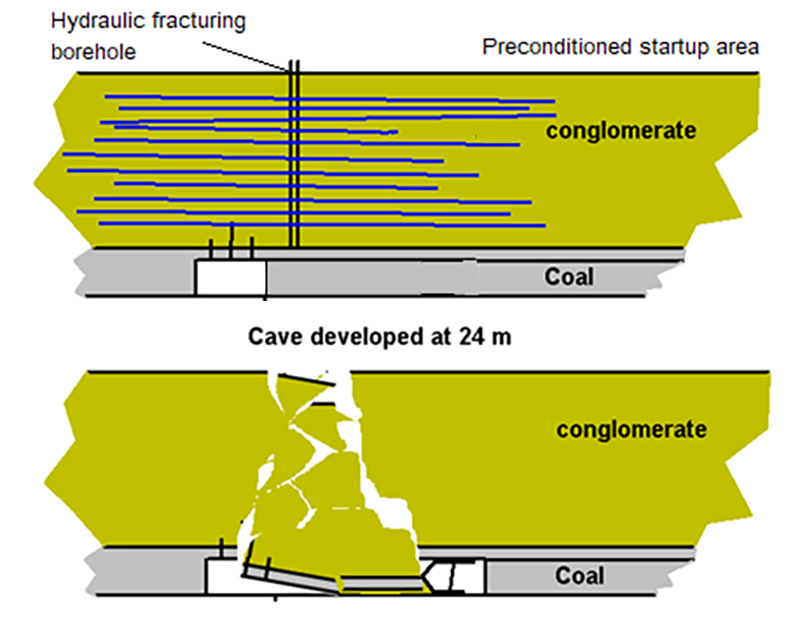

Since then hydraulic fracturing has been applied to caving issues at several other coal mines and at numerous metal mines, worldwide. In these mines, fracturing has proven to be effective for cave inducement and preconditioning of rock to enhance caving and reduce the risk of large seismic events. The significant benefits of detailed characterisation of the ground conditions, in situ stresses and caving behaviour for the design and implementation of hydraulic fracturing systems has been demonstrated again and again. Faster start up and consistently better outcomes are achieved when the ground conditions are properly characterised, the in situ stresses measured and the caving behaviour understood.

To Discuss how we can assist your next project

Figure 1: Hydraulic fractures were used at Moonee Colliery to induce caving of roof behind the longwall supports. Boreholes were drilled up into the roof from the face with injection hoses trailed into the goaf. Fracturing was then used to produce a controlled caving event.

Figure 2: Strong roof rock was preconditioned by placing hydraulic fractures from a vertical borehole drilled from the surface. Caving initialled after 24m of retreat during longwall startup.