87%

Improvement in

Bench Elevation

Accuracy*

30%

Reduction in

Shovel Hang Time*

25%

Reduction in

Unplanned

Maintenance*

100

Billion Additional

Tons of Optimized

Haulage*

Introduced 40 years ago as mining’s first computer based dispatching tool, the DISPATCH Fleet Management System (FMS) revolutionized the way mines work in real time. Today, the DISPATCH system is the most trusted FMS in the Industry.

The DISPATCH system for open pit mines maximizes productivity and efficiency while simultaneously increasing safety and control. Using state-of-the-art field hardware and communications software, and proven proprietary algorithms, the DISPATCH delivers unrivalled haulage optimization

Additional features of the FMS include GPS-based equipment positioning, asset health monitoring, maintenance, tracking, material blending, and production reporting. With four decades of recognition for its optimization capabilities and more than 250 deployments worldwide, the DISPATCH FMS is considered the industry standard for fleet management.

VIEW CASE STUDIES

Because precise to plan is your only option

For more than 20 years, mines around the world have used ProVison machine guidance systems to increase their total tonnes moved, improve the accuracy of material movement, and decrease costs associated with working outside of the mine plan.

The ProVision system is available for loading equipment (loaders, shovels and backhoes), dozers and drills. Leverage the systems high-precision guidance capabilities to improve your mine compliance through:

- A continuous feedback loop to your mine planning system to achieve better synergy between departments

- Immediate communications to your equipment operators about changes to the plan

- Intuitive operator elevation controls (not a confusing numeric display) to increase accuracy and minimize rework

The MineAlert Collision Awareness System (CAS) is an early-warning that alerts equipment operations to potential collisions with other CAS-equipped vehicles, helping to improve your operator’s safety awareness and reduce the likelihood of vehicle-to-vehicle collisions.

To minimize false alarms, predictive algorithms analyse the location, speed and trajectory of all vehicles in the monitored vicinity, generating alerts only when potentially hazardous conditions exist. By generating alerts that your operator’s helping you drive a zero-harm workplace.

You want to collect a wealth of data about your fleet’s health. But what will you do with it?

87%

Improvement in

Bench Elevation

Accuracy*

30%

Reduction in

Shovel Hang Time*

25%

Reduction in

Unplanned

Maintenance*

100

Billion Additional

Tons of Optimized

Haulage*

LOAD & HAUL

Mine Compliance

Safety

Maintenance & Reliability

Archived at customer sites*

Introduced 40 years ago as mining’s first computer based dispatching tool, the DISPATCH Fleet Management System (FMS) revolutionized the way mines work in real time. Today, the DISPACTH system is the most trusted FMS in the In40dustry.

The DISPATCH system for open pit mines maximizes productivity and efficiency while simultaneously increasing safety and control. Using state-of-the-art field hardware and communications software, and proven proprietary algorithms, the DISPATCH delivers unrivalled haulage optimization

Additional features of the FMS include GPS-based equipment positioning, asset health monitoring, maintenance, tracking, material blending, and production reporting. With four decades of recognition for its optimization capabilities and more than 250 deployments worldwide, the DISPATCH FMS is considered the industry standard for fleet management.

The DISPATCH 6 FMS introduces many exciting enhancements, including a streamlined user interface, turn-by-turn navigation, advanced tire management tools, and a new enterprise reporting engine.

VIEW CASE STUDIES

Because precise to plan is only option

For more than 20 years, mines around the world have used ProVison machine guidance systems to increase their total tonnes moved, improve the accuracy of material movement, and decrease costs associated with working outside of the mine plan.

The ProVision system is available for loading equipment (loaders, shovels and backhoes), dozers and drills. Leverage the systems high-precision guidance capabilities to improve your mine compliance through:

- A continuous feedback loop to your mine planning system to achieve better synergy between departments

- Immediate communications to your equipment operators about changes to the plan

- Intuitive operator elevation controls (not a confusing numeric display) to increase accuracy and minimize rework

VIEW CASE STUDIES

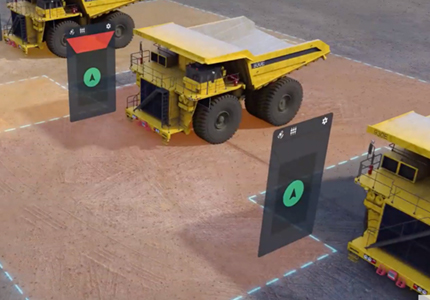

The MineAlert Collision Awareness System (CAS) is an early-warning that alerts equipment operations to potential collisions with other CAS-equipped vehicles, helping to improve your operator’s safety awareness and reduce the likelihood of vehicle-to-vehicle collisions.

To minimize false alarms, predictive algorithms analyse the location, speed and trajectory of all vehicles in the monitored vicinity, generating alerts only when potentially hazardous conditions exist. By generating alerts that your operator’s helping you drive a zero-harm workplace.

You want to collect a wealth of data about your fleet’s health. But what will you do about it?

The MineCare Maintenance Management system leverages intelligent computing capabilities to capture the right data at the right time. This predictive technology enables the step changes you need to digitally transform your maintenance process. Helping to extend your equipment life and reduce total cost of ownership (TCO)

Capture the Right Data, at the Right Time, for the Right People. The MineCare solution drives more than just data – it drives action.