Company Insight

Sponsored by Geographe

Innovative Solutions to Mining Maintenance of Heavy Equipment for Increased Uptime and Safety in the Americas

How often do you consider enhancing safety practices at your mine site?

Main image credit:

In search of opportunities to optimise maintenance operations and tackle the disruption in parts supply for heavy mining equipment, collaboration between American miners and their partners around the globe continues to grow. Innovation and efficiency come together to achieve optimal performance and profitability, and having trusted partners in this journey is a game-changer.

Heavy equipment fleets' increased downtime is harmful to a mine site’s outcomes, and shared challenges faced by miners are the unsuitability of OEM parts to cope with wear and tear in the harsh environments where the machinery operate, as well as the safety risks involved in maintenance operations.

Komatsu haul truck Rear Suspension Pins are often prone to seizing, requiring the need for hot works permits to lance out the pins. This practice increases the safety risks for the workforce and maintenance costs for the mine site with increased fleet downtime and deviations from safe work practices. When thermal lancing is used, a boilermaker can often take 5-8 hours to remove the two pins required to remove one rear suspension cylinder.

By identifying this challenge in collaboration with their customers, Geographe, an Australian innovator, developed the Enhanced Performance (EP) Colleted Pin Assembly (CPA) to suit the Rear Suspension of Komatsu 830E and 930E haul trucks. This solution offers complete interchangeability between Komatsu and Geographe Enhanced Performance parts.

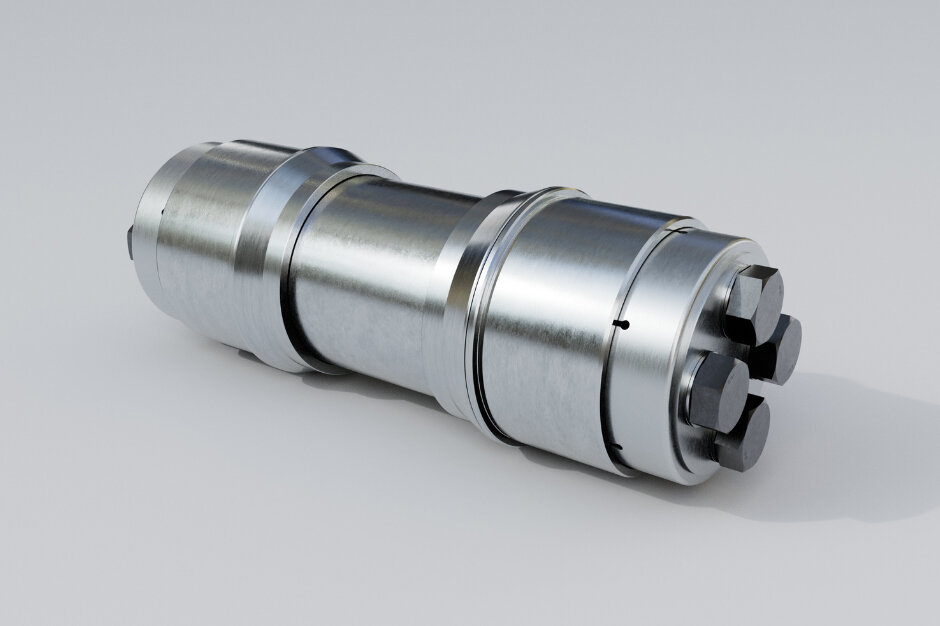

Geographe Enhanced Performance Colleted Pin Assembly

Incorporating a tapered collet system which creates a self-wedging effect between the pin and frame bores, the CPA’s wedging effect creates an interference fit and significantly reduces seizure. An in-built jacking system within the collet allows for a simple procedure to remove the collets when required.

Besides eliminating the need for thermal lancing and decreasing deviation from safe working procedures, the CPA eliminates tyre handling, reduces the risk of damage to the mating frame, and its multi-bolt design ensures collets pull up evenly and securely.

To provide a complete solution to miners, Geographe developed CPA Tooling Kits as part of their Specialised Tooling range. The CPA was specifically designed to aid in the fitting and removal of CPAs on the Komatsu 830E & 930E haul trucks. The CPA Tooling Kit features purpose-built components meticulously engineered for optimal performance, streamlining operations by consolidating all essential tools into a single case.

Geographe Colleted Pin Assembly Tooling Kit to suit Komatsu 930E haul trucks

Crafted from lightweight materials, the CPA Tooling Kit enhances convenience and productivity as it allows for effortless operation by a single person. The seamless compatibility of the components further enhances operational efficiency, delivering outstanding performance in every use.

Mining operations using the CPA Tooling Kit have reported improved productivity, reduced operational costs, and a safer working environment.

Geographe’s expansion to the Americas allows local miners to leverage Geographe Enhanced Performance Parts and Specialised Tooling Solutions in their sites, allowing them to improve their indicators for safety, productivity, and effectiveness. Led by Geographe's Senior Vice President of Sales & Business Development, Andrew Lindsay, the company aims to support customers in addressing critical maintenance challenges through innovative solutions and enhancing maintenance practices.

To learn more about the Geographe EP CPA and CPA Tooling kit, book a chat with Andrew here.

Contact information

Geographe

480 Abernethy Road,

Kewdale WA 6105

Tel.: +61 8 9449 1111

Email: sales@geographe.com.au

Web: www.geographe.com.au