Interview

Using satellites to maintain mine safety

For Australia's remote and hard-to-reach mine sites, satellites are emerging as crucial technology to keep workers connected and safe. Scarlett Evans speaks to Ashley Neale of Vocus about how this tech can be leveraged.

Ashley Neale, head of space and wireless operations at Vocus.

In Australia, where some the nation’s largest mines are located in isolated or off-the-grid areas, satellite technology is emerging as a crucial means of keeping teams connected during emergencies, thus improving miner safety.

Telecommunications company Vocus is one provider of such technology. An authorised reseller of Starlink’s satellite terminals, Vocus’ system was put to the test last year when a mining company’s communication tower went down in a bushfire. The miner relied on its newly installed satellites to coordinate an emergency response and prevent the damage from extending any further.

We speak to Ashley Neale, head of space and wireless operations at Vocus, about the incident, as well as how rolling developments in the reach and specs of satellites are transforming health and safety standards in mining and beyond.

Scarlett Evans: Could you tell me about the incident. How did your tech help?

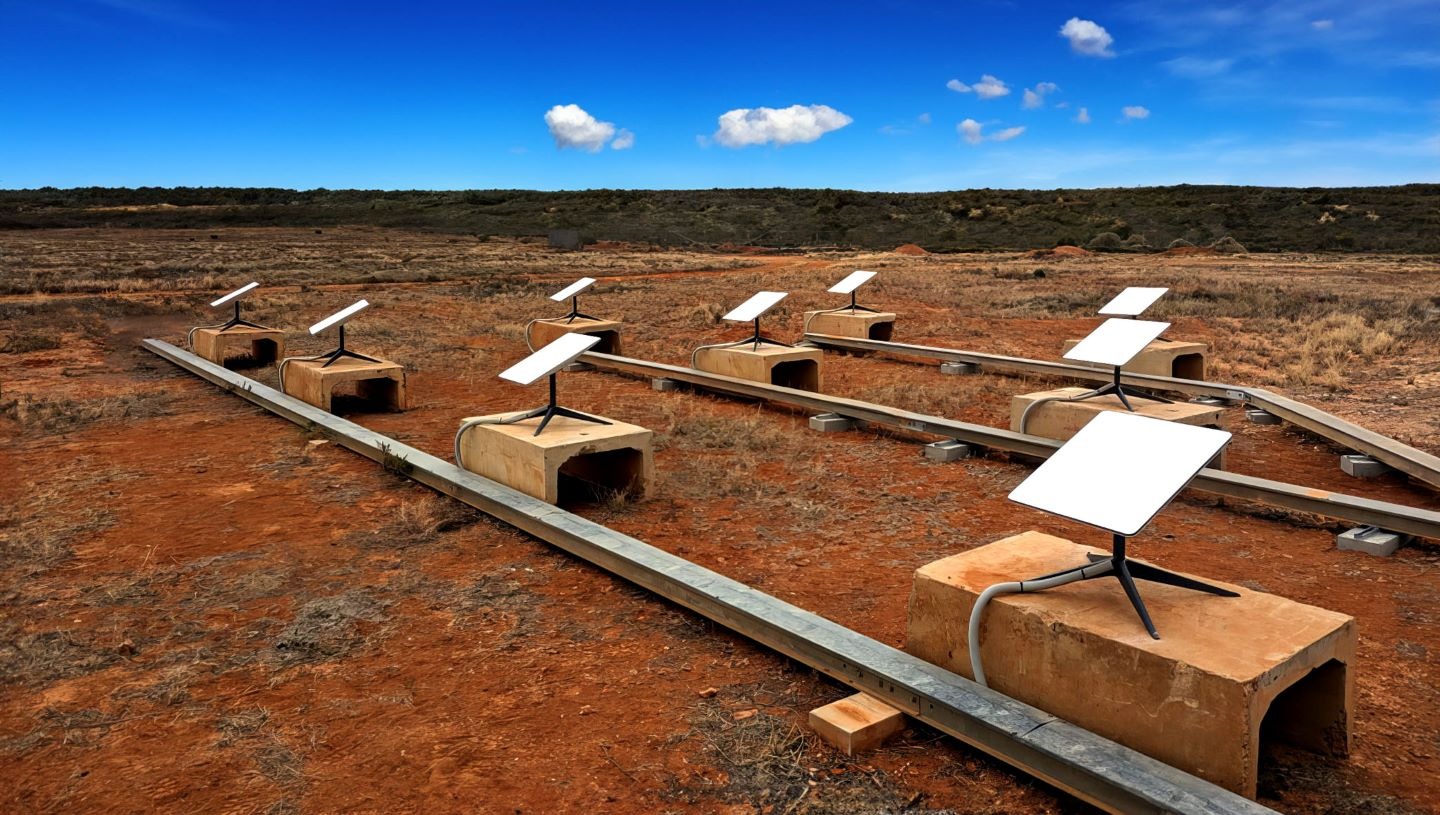

Ashley Neale: One of our customers, a mining operation, had an off-site microwave comms tower as their primary communications link for their site. Unfortunately, it was badly damaged in a bushfire, but coincidentally, Vocus had recently set up satellite terminals at the site to support worker welfare. This installation bonded together eight low Earth orbit (LEO) services from Starlink into a single very high-speed connection. It was specifically designed to provide streaming entertainment and video calling for people working at the site, not run the mine’s operations, but when the microwave tower went down the mine was able to switch operational comms over to the bonded satellite, preventing any gap in production at the mine.

The reason this is significant is that traditionally, satellite services haven't been ideal or able to provide proper corporate backup because they're not fast enough. The latency of the service is inappropriate for corporate use where responsiveness of the connection is key, however bonded satellite services have completely changed this paradigm.

Scarlett Evans: Could you elaborate on what a bonded satellite service is, and its benefits?

Ashley Neale: Traditionally, you have a single satellite service, and you’re limited to the speed of that single service. With bonded services, you get multiple satellite links combined – I think the maximum we’ve done has been 16 all together. You effectively create an aggregate of all these links to provide a faster service, and this is really important because if something as simple as an antenna breaks, your service doesn’t go down.

An array of eight Vocus Satellite – Starlink terminals bonded together into one very high-speed link at a mining site. Credit: Vocus

Scarlett Evans: Are we already seeing satellite tech being deployed across a lot of mine sites? What other benefits can it bring aside from safety?

Ashley Neale: Mining operators have always seen communications as a key part of their safety approach and they are always trying new technologies to achieve this goal – the mining industry was probably one of the first industries within our customer base.

Satellite tech has a lot of different applications within the health and safety bracket. It can be used for telemedicine; providing video coverage of mine sites, ensuring the right type of health resources are accessible when you need them etc.

Using satellites for entertainment and communications is also instrumental in ensuring mental health at mine sites. It may seem like something that’s just nice to have, but mine sites without good quality entertainment have a higher degree of depression within their staff.

What's been so transformational in the satellite communications market, and also for the mining industry, is that they’re now looking at sat comms and saying, actually, it's cheaper, faster and higher quality to get a satellite service out to this site than it is to use, say, a microwave link.

Nothing is going to beat fibre in terms of speed, but because so many of these mine sites are so remote, it’s just not economically viable to put a fibre cable out there. With Starlink, and LEO services in general, now mines don’t have to pay the communications tax to build their sites remotely. You are looking at installation for under $10,000, rather than the hundreds of thousands or even million dollars for traditional infrastructure.

Scarlett Evans: Are there any barriers to satellite deployment in this context?

Ashley Neale: I wouldn’t say it’s a barrier but one of the challenges we’ve noticed after having bonded satellite services out for a couple of years, is the creativity of where miners want to put the technology.

Traditionally, you'd have a single point where the fibre or satellite service would link to. With this new antenna technology, you can now connect everything that's on a mine site. So instead of just putting satellite terminals in the main office centre, miners are saying they want to put one on every vehicle from the site.

Instead of just putting satellite terminals in the main office centre, miners are saying they want to put one on every vehicle from the site.

This creates as much of an opportunity as a challenge, because it means as workers are driving around they’re gathering data, and connecting mine sites like never before. But you have to collect data from a range of systems – engine management systems and driver management systems, all connected back to the head office, and you have to integrate this technology with multiple third-party systems. That’s where the challenge is – how we integrate the satellite tech with all the other systems that are out there. That is where we need to see new skills coming into the equation.

For example, we build private 4G and 5G mobile networks across mine sites – these can cover vast distances that Wi-Fi simply isn’t designed for. We can integrate Starlink, fibre or microwave as the connection to the world, and use 4G/5G to connect the fleet of mine vehicles and devices within the mine.

But for prospecting where teams are moving into locations temporarily, it is hard to beat LEO for rapid deployment, with the appropriate rugged deployment and security solutions over the top.

Scarlett Evans: What other projects does Vocus have?

Ashley Neale: We have a strategic partnership with Google to help deliver their Australia Connect project, which is a 42,500 kilometer cable system running from the West Coast of America to Singapore via Australia, going via the north-west and east coasts of Australia. We are also delivering a terrestrial segment of that, from Darwin to Brisbane, where we are running their cable system over a Vocus terrestrial cable.

Network map showing the Google Australia Connect cable system. Credit: Vocus

The project is actually very relevant for mining, because it provides the highest capacity connectivity ever connected to Australia, meaning miners will have very, very fast connectivity to head offices in Singapore. This is important because it means you can run cloud applications on your mine site with minimal latency, minimal delay.

You can also connect to regional data centres within Australia, which might be collecting and processing data from all the sensors across the mine site, making decisions and sending all that information back to head offices in Singapore.