Company Insight

Sponsored by Futong Welding

FUTONG: Maximizing wear life for a lower total cost of ownership

Standfirst...

Main image credit:

After an exciting few days at MINExpo 2024, Futong Welding reflected on a highly successful exhibition that reinforced their growing presence in the wear industry. The booth drew attention from a diverse array of attendees, including representatives from Brazil, Chile, Colombia, Mexico, and across North America. The level of interest in their smooth surface CCO plates was exceptional, and the team was enthusiastic about engaging with such an attentive audience.

In this Q&A article, Futong Welding shares some of the top inquiries received from MINExpo attendees and insights gained from conversations, as they continue to build on the momentum generated at the event.

Caption. Credit:

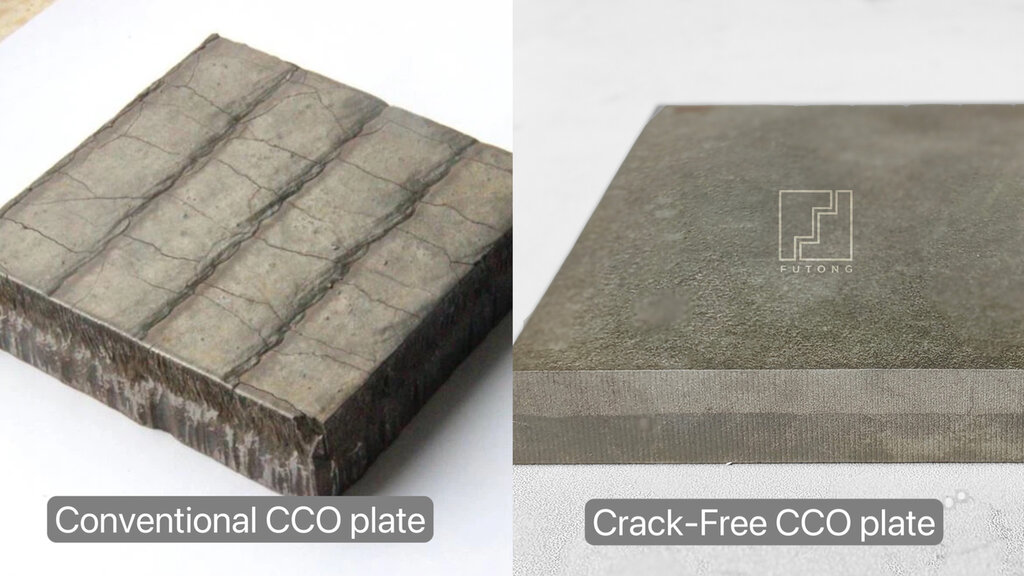

What sets you apart from conventional CCO?

A key factor is the carbide distribution in our alloy layer. Unlike standard chromium carbide, which tends to be bulky and unevenly distributed, our chromium carbide particles are extremely fine and evenly dispersed throughout the alloy matrix. This significantly reduces the risk of cracks and premature failure caused by hard particle impacts, as it minimizes the gaps between the carbide particles. The unique crack-free surface also promotes smoother material flow, preventing build-up and carry-back in sticky environments. This results in better efficiency and reduced downtime, making our plates ideal for high-wear applications.

Surface comparison.

How does your plate perform against AR steel or QT steel?

Many of our clients come to us after their quenched and tempered (QT) or abrasion-resistant (AR) steel liners have underperformed in extremely high wear applications. These clients often handle hard ores and aggregate, leading to significant wear damage and prompting them to seek more advanced solutions. In most cases, with the right overlay thickness and wear protection design, FT plates can extend wear life up to10 times compared to Q&T plates, depending on the impact level.

Futong team at the MINExpo.

It is true the harder the tougher it becomes?

Hardness alone doesn’t guarantee better wear resistance. It’s important to compare hardness values only within the same material category. For example, a quenched Q&T plate with a hardness of 58 HRC will generally offer better wear resistance than one with a lower hardness rating. However, our CCO plate, also rated at 58 HRC, provides superior wear resistance compared to a 58 HRC Q&T.

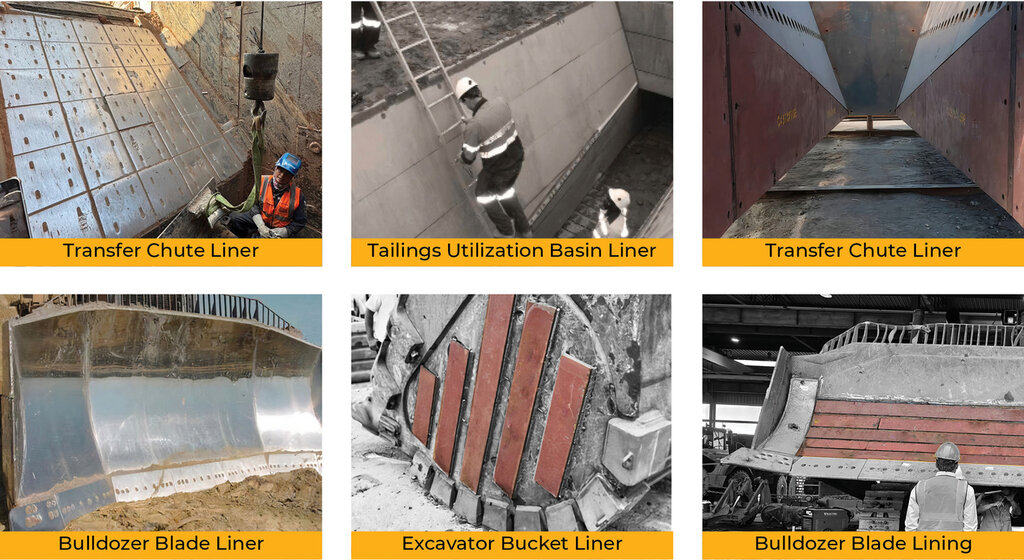

What projects have you been supporting? What are the typical applications?

Over the past 15 years, we've partnered with wear solutions providers and welding companies to help mining projects extend plant service life and prevent productivity loss. From iron ore in WA to copper mines in Tibet, our liners have proven effective in the toughest, most abrasive conditions. Our products are ideal for industries like mining, aggregate, and cement, where equipment faces constant abrasion and impact damage. Our wear liners protect critical components like transfer chutes and ground-engaging tools (GET), reducing downtime and cutting maintenance costs by shielding equipment from severe abrasion and impact.

Client success from real world applications.

If you missed FUTONG at MINEXPO, here is an interview of the founder and managing director of FUTONG WELDING:

Caption

Join FUTONG Welding/FuseTech at IMARC 2024, booth R33, from October 30 to November 1, to discuss your wear challenges and explore how crack-free plates can help.

Contact information

Futong Welding Co Pty Ltd

No.28, Shunyuan Rd,

ChangZhou, Jiangsu, 213002

Tel.: +86 13806119132

Email: info@futong-welding.com

Web: www.futongwelding.com