Event Report

MINExpo 2024 in review

MINExpo 2024 showcased cutting-edge mining technologies, with a focus on electrification, sustainability, and automation. Caroline Peachey reports.

MINExpo 2024 displayed some of the latest mining equipment. Credit: Lucas Friend

Hosted by the US National Mining Association (NMA), MINExpo 2024 took place in Las Vegas from 24-26 September, and drew over 45,000 attendees from 148 countries.

Rich Nolan, NMA president and CEO, said the “response this year was beyond what we could have expected, with unparalleled networking and dealmaking like we’ve never seen before.”

With 2,000 exhibitors showcasing a vast array of mining equipment – from giant trucks to tyres, pumps, valves and software solutions – MINExpo offered an unrivalled snapshot of the industry’s latest advances.

In addition, panel sessions brought together leaders from some of the world’s largest mining companies to discuss how the sector is evolving through innovations in electrification, digitalisation and other emerging technologies.

Electrifying equipment on display

On the first day of MINExpo 2024, Fortescue signed its largest ever single contract with equipment maker Liebherr to co-develop and validate a zero-emission mining fleet.

The deal, worth up to $2.8bn, would see iron ore producer Fortescue purchase around 360 autonomous battery-electric trucks, 55 electric excavators and 60 battery powered dozers, for use at its operations in Western Australia (WA).

The pair also unveiled the T 264 autonomous battery-electric dump truck, a product of their joint development efforts. The T 264 “will be one of the first zero-emission solutions for mine haulage in operation globally,” according to Fortescue’s CEO, Dino Otranto. It is expected to start on-site validation at the end of 2025.

Caterpillar also displayed its battery-electric Cat R1700 XE load-haul-dump (LHD) for underground mining alongside several new solutions for charging. Notably, the company announced its new dynamic energy transfer system, which can power both battery-electric and diesel-electric large mining trucks, is set to be tested at various BHP sites, including Jimblebar in WA and Escondida in Chile.

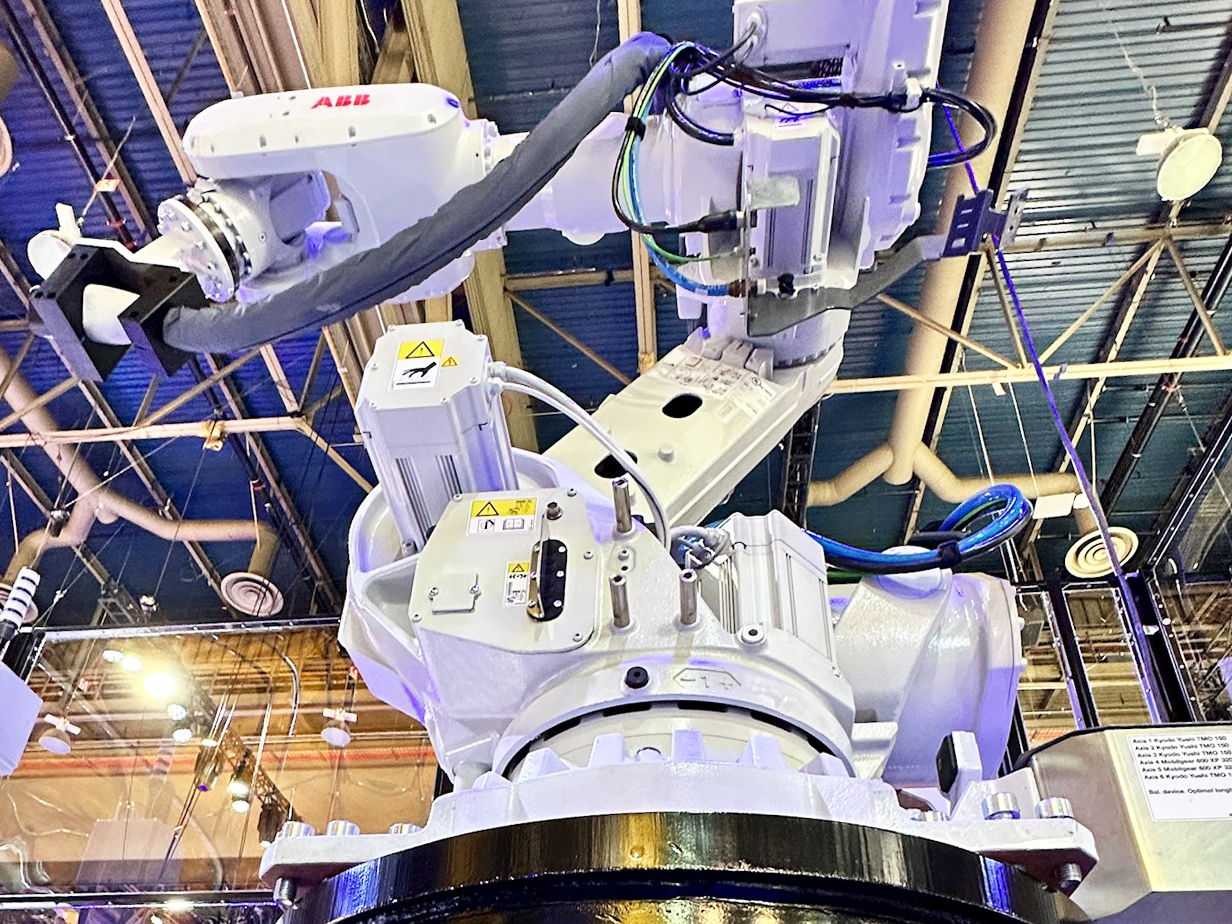

The eMine™ Robot Automated Connection Device was on display to the industry for the first time at MINExpo 2024. Credit: ABB

MINExpo 2024 also saw Komatsu reveal a new charging solution that supports its first battery-electric LHD, the 4-tonne-class WX04B, designed for narrow vein underground mining operations. Also on show for the first time, was the eMine™ Robot Automated Connection Device (ACD), currently under development by ABB and Komatsu in collaboration with mining companies Boliden and BHP. The tech, which has been tested at ABB’s lab in Sweden, is set to start on-site demonstrations at Boiden’s Aitik open-pit copper mine in the fourth quarter of 2024.

Also making its way from MINExpo for a one-year field trial at Aitik in Sweden will be Komatsu’s Power Agnostic 930E. As the name suggests, the 930E haul truck can be converted from diesel to various types of fossil-free power sources, allowing customers to “future-proof their operations with a versatile approach to decarbonisation”.

Boliden will trial Komatsu’s Power Agnostic 930E truck at its mine in Sweden. Credit: Komatsu

Sustainability in focus

Even beyond electrification, sustainability remained a core focus at MINExpo 2024.

During the event, Schneider Electric announced a partnership with Glencore to transform its copper supply chain and enhance decarbonisation efforts.

“In the past, lowering emissions has been a challenge due to the complexity of supply chains. But, by leveraging digitisation we are able to close the material loop and boost our circularity,” said Rob Moffitt, president of mining, minerals and metals at Schneider Electric.

Rob Moffitt, president of mining, minerals and metals at Schneider Electric pictured with Mining Technology’s editor, Caroline Peachey at MINExpo 2024.

As part of this collaboration, Schneider aims to help Glencore produce sustainable copper, which it will purchase from Glencore to use throughout its network of sub-suppliers to manufacture equipment. The intention is for the copper and electronic waste to be taken back at the end of life, with the materials returned to Glencore for recycling.

Moffitt told Mining Technology that similar agreements could be put in place for other commodities.

“We are working with a very large, what’s going to be a greenfield aluminium project in the US … upstream, in terms of helping secure funding from government and other investors, but also downstream with some of our customers who are interested [in] securing supply of green aluminium into their processes,” Moffitt said on the sidelines of MINExpo.

Improving the efficiency of mining equipment

Tyre giant Michelin also picked MINExpo 2024 to debut what it claims is mining’s “first-ever energy efficient tyre”. Commercially available in 2025, the Michelin XDR 4 SPEED ENERGY™ tyres offer a 3.6% fuel efficiency improvement compared to the XDR 250, equating to potential savings of $1.2m per year for a fleet of 50 trucks.

The XDR 4 tyres were on show on the T 264, with Liebherr saying in a press release its “new energy-saving rubber compound and optimised tread … help reduce the amount of energy consumed by mining haul trucks.”

Bridgestone, too, unveiled two new radial tyres designed for load haul dump loaders. The VMMS and VMDL underground tyres are manufactured with a unique tread pattern and offer greater load capacity, longer wear life and more cut resistance than previous models. It also launched the new Firestone Super Rock Grip™ Deep Tread Loader Dozer 2 (SRG DT LD 2) tyre, which is approved for Komatsu and Caterpillar loaders.

Lubricants offer another opportunity to improve equipment efficiency. As ExxonMobil told Mining Technology during MINExpo 2024 “huge focus” in the industry right now is on reducing fuel consumption; something it can support with its synthetic lubricants.

“We drive fuel efficiency among a lot of the equipment that we interface with,” explained Brian Willner, North America finished lubricant sales director, ExxonMobil. “That helps our partners in the industry achieve their GHG [greenhouse gas] and sustainability missions.”

The battery electric T 264 was unveiled for the first time at MINExpo 2024. Credit: Liebherr

Producers push for innovation

Senior mining executives discussed the industry’s commitment to sustainability and innovation during a panel session on the first day of MINExpo.

Vicky Peacey, general manager, Resolution Copper, shared that Rio Tinto is trialling Sandvik underground battery electric haul trucks and loaders at its Kennecott mine in Salt Lake City, Utah, as well as much larger Cat 793 battery-electric haul trucks in WA.

Resolution Copper is a joint venture between Rio Tinto (55%) and BHP. It is aiming to develop one of the largest proposed copper mines in North America, with an estimated resource of 1.787 billion metric tonnes at an average grade of 1.5% copper.

“Thinking about remote, deep mines – and Resolution is one – we're able to use machine learning (ML) and AI to take all the data that we have, the geotechnical information, and view it in a way that human brain cannot imagine,” Peacey added.

Another area where AI is “yet to scratch the surface” is in predictive maintenance, according to Paul Lang, president and CEO of coal-producer Arch Resources.

However, Mitch Krebs, president and CEO, Coeur Mining, a precious metals producer with operations in Mexico and the US, illustrated how predictive modelling and ML supported expansion of its Rochester silver and gold mine, in Nevada.

Producer panel at MINExpo 2024 from left to right: Denise C. Johnson, group president of Caterpillar; Cassie Boggs, interim president and CEO, Hecla Mining Company; Mark Bristow, president and CEO, Barrick Gold; Mitch Krebs, President and CEO, Coeur Mining; Paul Lang, CEO Arch Resources and Vikki Peacey, General Manager, Resolution Copper. Credit: Caroline Peachey

“We implemented a predictive model through machine learning… to help predict the product size that is coming through a new three-stage crusher [at Rochester], so that operators can make adjustments much faster than they ever could before. That ends up getting them that product size that we need out to the leach pad to maximise the recoveries.”

Still, there is still a way to go for the mining industry in its push for automation, Mark Bristow, president and CEO, Barrick Gold explained.

“Sometimes we get confused about promoting and delivering innovation and automation,” Bristow stated, adding that the mining industry has “a long way to go and become efficient.”

“What has happened is the automation side of it is starting and… we can celebrate the fact that we mine remotely now from the surface, and that opens up the workforce,” Bristow said.

He pointed to the Callio FutureMINE project in Finalnd, which Barrick is working on in collaboration with BHP, Anglo American, several contract miners and OEMs.

“We are using space technology – communication, repairs, maintenance – and [looking at] how we engage with people remotely, rather than [having] to get an expert to visit the mine.”

“Covid taught us a lot about the power of remote engagement, so that is an exciting frontier that is just starting to open up,” Bristow concluded.

Save the date for MINExpo INTERNATIONAL 2028!

26-28 September 2028