Company Insight

Sponsored by GIW Industries

Best In Class Pumps

KSB is the best-in-class pump provider for the mining industry. KSB has over 150 years of pump design and expertise. We provide best in class slurry and process pumps for mining, industrial minerals and dredge applications.

KSB offers comprehensive services to help relieve the pressure and reduce the life cycle cost of your most challenging pump problems.

KSB’s newly expanded manufacturing facility in Grovetown, Georgia USA serves as the headquarters for GIW® Slurry Pumps. KSB designs and manufactures all-metal and rubber-lined pumps in a variety of abrasion and corrosion-resistant gray iron, ductile iron and white iron, and steel alloys.

With our global team of experts, solutions and supply chains, we make the life of our customers easy and successful.

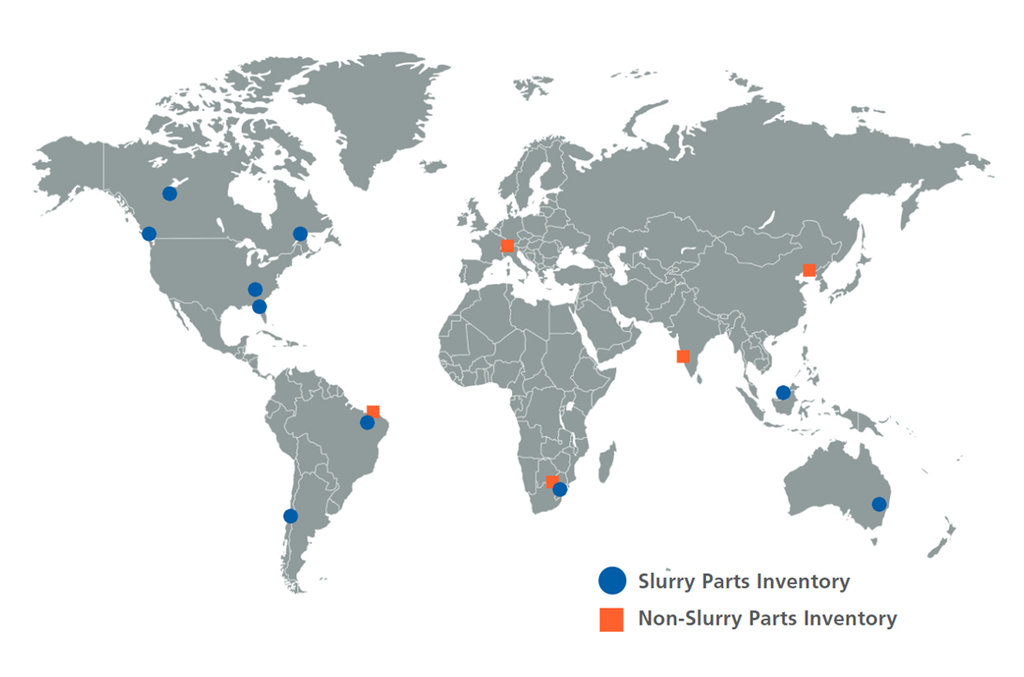

Secure supply chain & local inventory

Our commitment to service is more than a promise; it is a resource you can count on to keep your equipment up and running. With a global network, you can rest assured you will have local inventory and technical support when you need it.

We are here to serve you. Wherever you may be.

- 37 Production Sites in 18 Countries

- 3500 Worldwide Staff

- 190 Workshops

- 10 Major Slurry Parts Warehouses

- 9 Foundries on 3 Continents

- 1 Center for Additive Manufacturing

- 5 Central Spare Parts Warehouses

KSB’s Global Supply Network

Local technical support and service.

KSB offers 24/7 service and repair support around the world. Local technicians help you troubleshoot operations, processes, and mechanical issues. They can also assist with inventory and parts replacement, analyzing wear patterns, and supervising preventive maintenance programs.

KSB offers comprehensive expertise to help relieve the pressure and reduce the life-cycle cost of your most challenging pump problems. KSB offers comprehensive expertise to help relieve the pressure and reduce the life-cycle cost of your most challenging pump problems. KSB brings knowledge and creative solutions to improve the equipment reliability and system performance to your plant to include:

- installation and commissioning of your equipment

- maintenance and repair

- customized service concepts

- spare parts or replacement

You can count on KSB to provide personal assistance when and where you need it—onsite or in the shop.

KSB offers comprehensive services to help relieve the pressure and reduce the life cycle cost of your most challenging pump problems.

Industry leading research and development

Research is the foundational block of KSB products and services. Our research has led to the development of innovative product features and solutions that help our customers succeed.

A recent innovation is the GIW® RAMSL (Remotely Adjusted Mechanical Suction Liner) technology that allows you to make suction liner adjustments during operation. The RAMSL technology reduces downtime and facilitates safe and reliable maintenance while minimizing overhead costs.

In 2022, KSB launched GIW® SLYsight, which is the industry’s latest in wear monitoring technology. While competitor’s systems estimate wear, GIW® SLYsight utilizes custom, strategically placed sensors to measure the actual wear rate of a pump’s parts, while the pump is running.

Superior hydraulic and material technology

KSB’s R&D provides invaluable insights that improve your slurry transport systems and increase operational efficiencies.

The state-of-the-art Hydraulic Lab located in Grovetown, Georgia USA performs pipeline tests on a wide variety of pumps and slurries. GIW is able to test every centrifugal slurry pump it manufactures, with impeller diameters up to 2800 mm (110 inch) in pipelines up to 1200 mm (48 inch). The Lab also has the capability to test slurries in a range of pipe sizes, measuring pump and pipeline solids effect, slurry rheology, solids bed formation, wear, and other important system design parameters.

KSB conducts a broad range of materials testing in our Grovetown Metallurgical Lab. From cutting-edge development on new materials, to the evaluation of parts returned from the field, our materials engineers explore all aspects of materials science related to slurry applications.

Our most recent development is Enduraclad™ bonded parts. This new material coating can extend the life of your parts by 50%, requiring fewer replacements, reducing maintenance costs, and limiting downtime revenue loss.

Our extensive R&D capabilities means that not only can KSB help you select the right pump for your application, but we can provide you with continuous product improvements.

Proven field results

GIW® Slurry Pumps operate all over the globe transporting a wide variety of materials. Wherever mining, dredging and industrial companies have challenging slurry transport needs, we can help.

GIW® MDX - Superior hydraulics and wear-resistant materials make the MDX the most reliable mill duty pump on the market. The MDX 750 pump was installed in a copper grinding circuit transporting class 4 slurry. The pumps run over 4,000 continuous hours, reducing maintenance shutdowns, and saving the customer 6 million USD per line.

GIW® TBC - No other pump can match the TBC‘s production capacity. It is the market leader in the Canadian Oil Sands for high-pressure hydrotransport applications. The TBC-92 was developed in response to a customer’s need to increase efficiencies in their production. The TBC-92 easily achieved the target of 6,000 continuous hours of operation. Longer run times, fewer outages, and increased production in severe duty applications translates to the lowest TCO in the market.

GIW® DWD - When designing pumps for dredging, it is necessary to design the pumps to accommodate a wide range of slurries and operating conditions. The DWD was developed to operate on the Spartacus Cutter Suction Dredge (CSD). The Spartacus was tasked with cutting harder soils and rocks from the seabed at speeds previously not achievable. The DWD features the robust design, efficient hydraulics, wear-resistant materials, and free large passage of rocks needed to get the job done.

Contact information

GIW Industries, Inc. (A KSB Company)

5000 Wrightsboro Road

Grovetown, GA 30813

United States of America

Tel.: +1 706 863 1011

Email: giw-marketing@ksb.com

Web: www.ksb.com/en-us