Annexus WA supplies, installs and maintains the DirtWhacker conveyor belt cleaning system.

Conveyor Belt Cleaning System

Dirt Whacker conveyor belt cleaner systems are recognized worldwide for their effectiveness, durability and belt-friendliness.

Our secondary cleaner, with its unique patented parallelogram design and air bladder system ensures a constant blade to belt angle of 90° and constant blade to belt pressure no matter the blade ware. The system is so effective that in the majority of installations, the pre-cleaning by a primary cleaner is not required.

The DirtWhacker cleaning system extends conveyor belt life, reduces blade ware and reduces ongoing maintenance.

Features:

- Extended conveyor belt life

- Constant blade to belt pressure

- Blades operate independently

- Constant blade angle of 90° due to patented parallelogram design

- Lower maintenance

- Longer blade life

- Less carry back

- Cleaner working environment

- Less down time

A COMPARATIVE TRIAL THE DIRTWHACKER vs A CONVENTIONAL BELT SCRAPER

In a coal application, the DirtWhacker Belt Cleaner was installed in a trial situation against a conventional spring-loaded belt cleaner. After 9 months, the belt with the conventional required replacement whereas the belt with the DirtWhacker belt cleaner lasted another 9 months. The reason for this dramatic difference is that the DirtWhacker removed a lot more of the coal from the belt, with less abrasive material passing over the blade and hence less abrasion on the belt. The big cost saving in this case was the replacement cost of the belt.

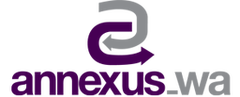

Conventional Belt Scraper

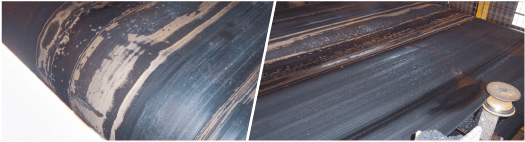

DirtWhacker Belt Scraper

CONVEYOR BELT CLEANING SYSTEM

- The cleaner blades are designed to bring about minimal belt wear to the belt top cover

- The innvative parallelogram design maintains the optimal belt blade angle irrespective of blade wear

- The air bladder system sustains even blade-to-belt pressure over the full cleaner width

- The blade design is cmpatible with the majority of mechanical belt fasteners

- The unit requires no mechanical adjustment in-between blade changes

- There is a visual indicatin of belt-to-blade pressure at all times

- The belt-to-blade pressure can be adjusted from a suitable remote location

Protecting the Future... Today!

Automatic-mixing two part urethane • No guesswork or messy measuring Repair, bond & seal virtually any surface • Fast setting • No downtime No solvents or VOCs • No odours • No shrinkage • Hot-Cold resistant No drip • Sandable, grindable, paintable, drillable & tapable

1

Available in various hardneses (60A - 98A) custom colours

& specific curetimes

2

Primers Available

for Different Applications

3

Automatic Mixing Tip Ensures Perfect Mixing

4

Top Loading

Dual Dispensing Automatic Mixing Unit

Avaliable in High Volume Pneumatic

hover over the numbers to discover more

Ideal for:

Concrete Repair

Fabric and Steel Cable Belts PVC and Urethane Belts Belt Lacing and

Clip Coverings

Elastomeric Repair

Rubber Linings

Urethane Linings

Off-Road and Forklift Tires Pulley Lagging • Pump Liners

Conveyor Belt Repair

Floors, Containments Walls • Cracks • Spalling Expansion Joints Threading and Mounting

STORAGE

SIZES / COLOURS

U-REPAIR is warranted to perform as claimed under normal circumstances. This warranty is limited to the replacement of defective product or to refund the purchase price of meterial if proven defective.

U-REPAIR has a shelf life of 12 months when stored properly in unopened packages at 18°C - 30°C. Do not expose to moisture. Opened product will remain good for 60 days.

U-REPAIR is available in black (standard), white, concrete gray, clear, green, blue, orange, yellow, tan & red or we’ll match your custom colour. Available in convenient 150x150ml, 200x200ml and 750x750ml sizes.

Annexus WA

Unit 3, 68 Callaway Street

Wangara, WA, 6065

+61 08 9302 2576 / 0408 607 465

solutions@annexuswa.com