Company Insight

Sponsored by Onirik World Group

Integrated Electro-resonance Remote and Field Sensing – A New Paradigm for Mining Exploration

Over the last 20 years, around the world, more than 400 successful experimental research and commercial projects have been carried out with Mineral Finder Technology (MFT). The projects have proven integrated satellite and field electromagnetic frequency-resonance methods solve several mining exploration problems.

Onirik partners with CTAC to deploy MFT, an exploration service and technology that slashes time and costs, improves precision, has no environmental footprint, and significantly improves success rates.

Mining exploration is overdue for a breakthrough

Traditionally mining exploration takes a long time, is costly, produces limited information, and has a low success rate. The mining sector is overdue for a technology driven performance disruption to streamline the exploration phase. MFT may be just that breakthrough.

What is the science

MFT involves the application of non-classical electromagnetic and spectral resonance science. The methodology focuses on the detection and mapping of a very specific substance – the target mineral (or oil, gas, or aquifers) – rather than the geology.

The methods are based on the frequency-resonance principles of electromagnetic sounding the natural electric field of the Earth. They study of the structure of the surface layer of the atmosphere, formed by ions of different signs, and polarisation zones at the boundaries of geological anomaly and change.

The approach used makes it possible to create:

a) compact light weight measuring equipment that is easy to transport and easy to maintain;

b) a methodology for field measurements (on foot, from a car, on a boat, from an aircraft);

c) effective technology for solving a wide class of environmental, engineering-geological, hydrogeological, and geological-geophysical problems.

It makes it possible to obtain preliminary exploration results with speed and confidence.

How can Onirik & CTAC help you with your exploration projects?

MFT has been used to quickly explore large areas of unknown potential, and identify subsections warranting detailed analysis, or where there is already evidence of mineral potential to explore precisely targeted areas in detail, or to reinterpret complex areas previously explored with traditional drilling methods.

The MFT process involves four phases. Phase 1 involves processing satellite multispectral data to identify anomalies indicating areas of subsurface mineralisation and the concentration of resources in those areas.

Phase 2 involves field sensing at greater levels of precision for the areas of most interest identified in Phase 1. The first step uses Forming Short Pulse Electromagnetic Fields (FSPEF). The second step employs Vertical Electro Resonance Sounding (VERS).

Phase 3 is where all the data from each prior phase is analysed and integrated with neural net and AI software and geophysics algorithms to quickly produce a final 3D map of the below surface deposits, assessment of the mineralisation grade, volume, and value. This is presented in a detailed report.

Phase 4 is where our team of geologists and geophysicists provide ongoing off-site and on-site support during your drilling program and during the mine design, construction, and operation phases.

MFT is a game-changer for exploration in the mining industry, as it addresses the major challenges of geophysics, time, cost, risk, and environmental impact that have traditionally frustrated the search for natural resources.

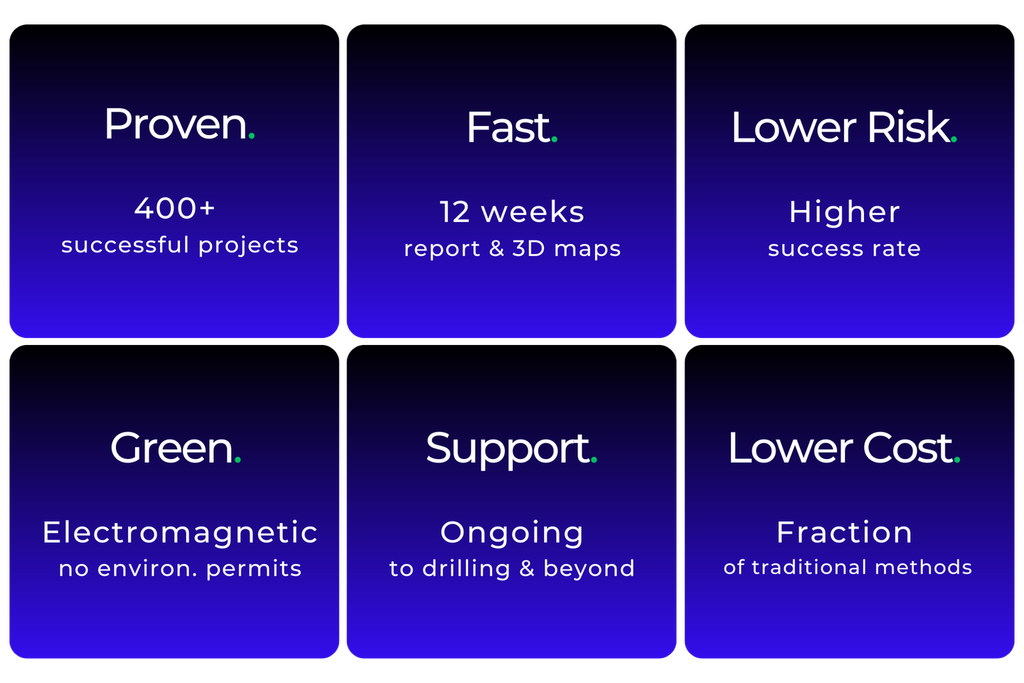

Key technical and business advantages of MFT at a glance

What makes MFT unique is that it is passive electromagnetic surveying. The science does not suffer from the skin effect and retains precision and confidence at depth. In every phase, it produces subsoil geophysics, up to 10 km deep.

One of the biggest benefits of MFT is the speed. MFT takes 3 months (12 weeks) in total. It is followed by a short, minimal, and targeted drilling program. The quick MFT process leads to shorter exploration cycles so you can evaluate more potential sites.

The current average success rate for transition from exploration to operation is around 5%. While success rate can be influenced by several factors that are unrelated to exploration process, the success rate on MFT projects is above 50%.

The combined MFT and drilling expense is 80% lower than traditional methods. The reduced cost also contributes to the capacity to evaluate more potential resource sites.

Mining exploration inevitably disturbs the environment, and environmental permits are required. The permit approval process and management of compliance can be long and costly. MFT has zero impact on the environment, so environmental permits are not required.

As one mining client described it, “MFT is an MRI for orebodies. A non-invasive environmentally friendly technology that yields accurate three-dimensional orebody maps quickly and for low cost.”

Get in touch with Onirik for more information

The mining leaders who have evaluated or employed MFT get excited because they grasp the impact it has on their exploration business model and the potential to accelerate of greenfield development targets to production.

Contact information

Onirik World Group

Level 6, 200 Adelaide Street,

Brisbane QLD, 4000,

Australia

Email: info@onirik.com.au

Web: www.onirik.com.au/mft