Company Insight

Sponsored by HNA Group

No more blind spots

Tyre Handler PTZ offers smarter tyre maintenance.

Main image credit:

The size and scale of tyre maintenance equipment alone makes safety a constant challenge. Heavy wheels, blind spots, and high-risk procedures are all part of the job for tyre fitters—until now. Bowen Basin-based innovators HNA Group have developed a cutting-edge PTZ (Pan-Tilt-Zoom) camera system designed to remove personnel from harm’s way.

HNA Group is no stranger to rethinking high-risk tasks. Known for engineering practical, site-ready solutions—from hydraulic tooling covers to burst sleeve kits and custom tooling designed to eliminate live work—the company has built a reputation for addressing critical safety concerns head-on. With clients such as BHP, Rio Tinto, and Liebherr, their work is being adopted across some of the most demanding operations in the country.

The latest addition to their growing list of safety innovations is the Tyre Handler PTZ Camera System, a purpose-built product developed with direct input from OTR (Off-The-Road) tyre bays. The core objective was simple: keep tyre fitters out of dangerous zones without compromising on visibility or efficiency.

“We asked ourselves—how do we get a clearer view of the wheel assembly during handling, without putting people in the line of fire?” said Anthony Lye, Director of HNA Group. “We also noticed that when tyre handlers were being used to break beads, the operator had no visual on the grab, relying instead on spotters. That’s a risk we wanted to eliminate.”

Built for the real world

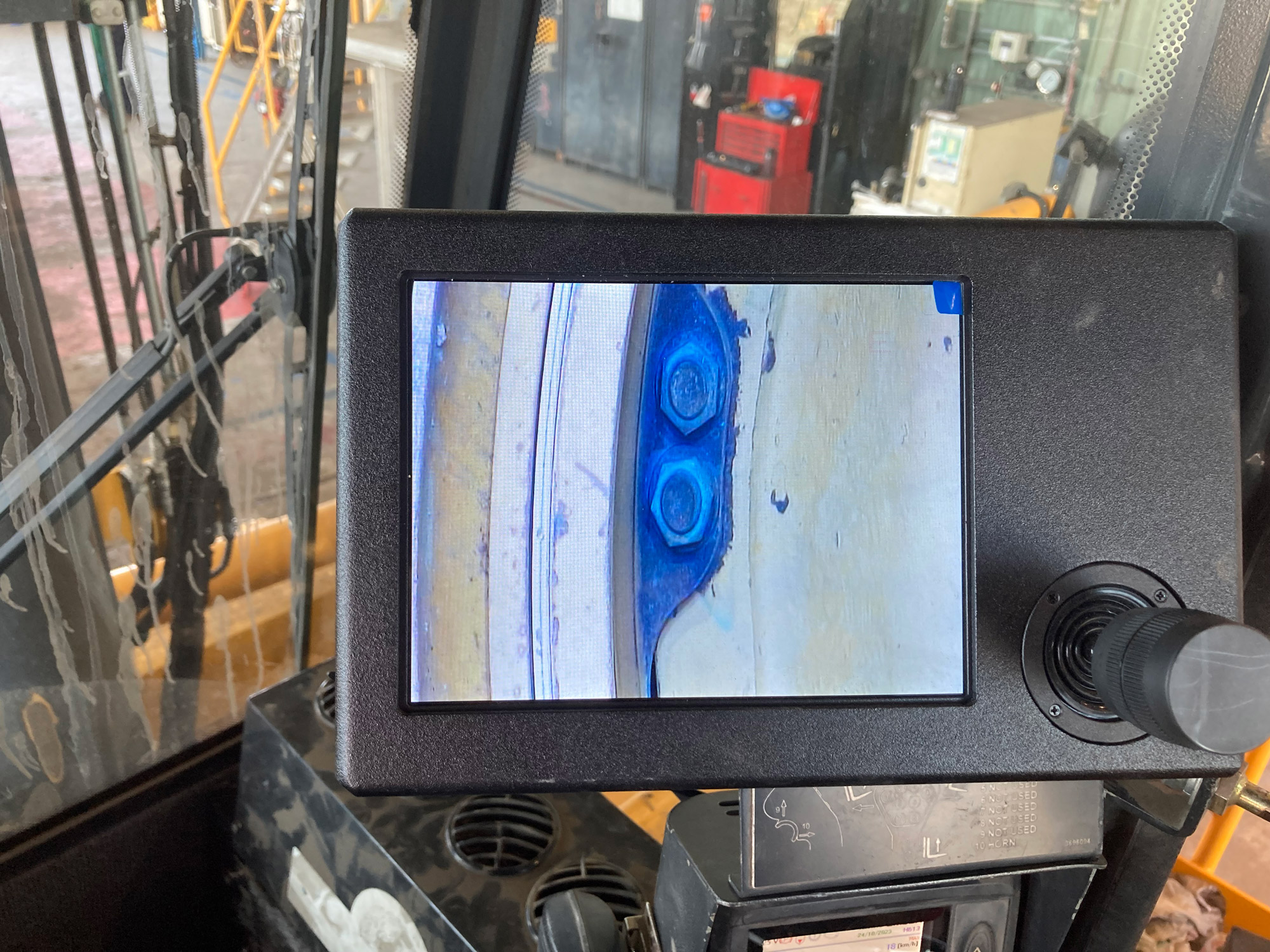

With that insight, the team engineered a prototype camera that could pan, tilt, and zoom—all controlled via a joystick from inside the operator’s cab. Crucially, it also includes infrared capability for low-light work and a large in-cab monitor to ensure clear, real-time visuals.

The Tyre Handler PTZ Camera System is built to survive mining environments.

But designing the system was only the beginning. Making it rugged enough for harsh mining environments meant a full suite of additional features: a waterproof, dustproof camera housing with vibration damping, a magnetised base for easy repositioning, and a braided, heavy-duty harness with Deutsch connectors. Additionally, the screen and joystick are encased in a powder-coated aluminium shell built to withstand everyday site wear and tear.

Once testing was complete, HNA rolled out a six-month field trial, which quickly earned praise from tyre maintenance teams on the ground. The result was a full-scale deployment across multiple BHP sites in Central Queensland. Eighteen months on, the system is now commercially available and ready for rollout across the mining industry.

Everything you need, straight out of the box

The Tyre Handler PTZ Camera System Kit is built with installation simplicity in mind. Supplied with a modified PTZ camera, preprogrammed screen, stainless steel handle assembly, vibration mounts, magnets, and a custom braided harness, the full package includes all the hardware required—down to the zip ties and stand-offs. Also included is a heavy-duty RAM mount for the in-cab screen, along with detailed wiring diagrams and fitment manuals.

Installation typically takes between four to six hours for two tradespeople, with the only electrical requirement being the termination of the harness and connection to a 24V accessories circuit. All fusing is conveniently located within the screen housing.

Designed with operators in mind

Ease of use was central to the camera system’s development. The joystick controller allows for intuitive operation of all camera functions—pan, tilt, zoom, and focus—without requiring additional screens or buttons. Once installed, the system powers up automatically with the machine’s ignition, keeping things simple and seamless for the operator.

The magnetised base offers flexible positioning of the camera, ensuring the best possible view of the task at hand. Meanwhile, the harness routing has been designed to integrate easily with existing equipment—up and over the mast sheave alongside OEM hoses. For machines without a spare pulley, HNA can provide a custom sheave solution.

Tyre Handler PTZ Camera at full zoom from 8 metres away.

Proven in the field, ready for more

What sets HNA Group apart is their hands-on approach—spending time in tyre bays, listening to the people doing the work, and developing tools that genuinely make a difference. The camera system is the latest in a series of purpose-built solutions aimed at creating safer, more efficient worksites, and it’s already delivering results for some of the industry’s biggest names.

Whether you’re looking to upgrade your current fleet or solve a specific visibility issue during tyre handling, HNA Group can tailor a camera system to suit your operation.

For more information or to discuss a custom setup, contact HNA Group today and take a proactive step toward safer tyre maintenance.

Contact information

HNA Group Pty. Ltd

Anthony Lye

Tel.: +61 041 244 6807

Email: anthony@hnagroup.com.au

Craig Hall

Tel.: +61 040 937 7930

Email: craig@hnagroup.com.au

Web: www.hnagroup.com.au