We don’t know what tomorrow’s

mining equipment will look like.

But we do know what will

contribute to its fire protection.

HIGH-TEMPERATURE INSULATIONS

FOR MORE SAFETY AND EFFICIENCY.

ⓘ

Thermamax Germany

+49 621 322 35 0

info@thermamax.de

Thermamax USA

+1 630 340 5682

infomail@thermamax.us

Thermamax China

+86 512 5377 1001

info@thermamax.cn

Even if we don’t know what the future holds, we can still be prepared for it. Today at Thermamax we already have solutions to meet the future requirements for Fire Protection and Exhaust Aftertreatment.

For our customers in the Off-Highway market sectors that means more confidence in their forward planning.

It means working with a partner today, who can take care of their needs for tomorrow.

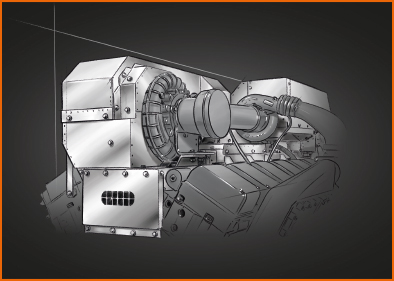

Tmax-Insulation Cladding for effective fire protection and improved reliability

Fire, personnel and failure protection is a key concern for construction site operators. Reduction of combustion risks due to high surface temperatures means reduced risk of fire as well as machinery failure – and therefore higher productivity.

Tmax-Insulation Claddings for engine compartments provides your equipment with the maximum in safety and operational reliability.

- Rugged and durable modular system

- Easy assembly and disassembly of parts using fixing points on the engine

- Effective protection for temperature sensitive components

- Increased and effective fire prevention and protection

- Ease of Maintenance

- Increased machine reliability

- Lower insurance premiums

- More effective exhaust after treatment, i.e. easier compliance with IMO emission values due to optimum surface temperature

- Effective noise protection

- Simple and clean design ensuring the insulation modules appear as an integrated part of the engine

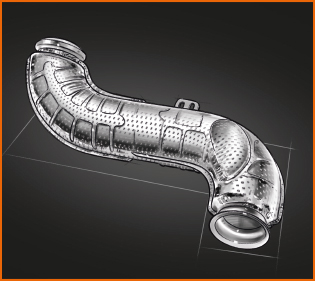

Tmax-Integral Insulation for the most effective exhaust gas aftertreatment and maximum in safety

Exhaust regulations are uncompromising – and our solutions for reducing emissions are too. Our experience with On-Highway applications allows us to offer you high quality insulation systems ensuring the most effective exhaust gas aftertreatment.

Tmax-Integral Insulations for exhaust lines are designed to ensure that temperatures from the engine to the exhaust systems can be controlled so precisely that optimum conditions for combustion and clean emissions exist while temperature-sensitive components are protected from heat transfer.

- Insulation system comprising insulation material with a metallic outer shell (stainless steel foil or thin plate), installation direct onto hot gas components, connection of the shells by welding or folded seams, non-removable

- Available with a special Tmax-foil design, i.e. SKELTEC or a micro-perforated outer shell, i.e. SONETHERM

- Effective exhaust aftertreatment due to lower thermal losses in the exhaust gases and increased efficiency of turbochargers, catalytic converters, diesel particle filters, and other performance-critical components

- Improved safety due to the prevention of excessive radiated heat or temperature rise in engine spaces

- Minimal additional weight due to use of thin material thicknesses

- Up to 150% increased stiffness, high strength and resistance to stone impact etc. and up to 50% weight-saving due to the use of SKELTEC

- Reduction of background noise and sound pressure levels, easier compliance with future noise emission regulations due to the application of SONETHERM

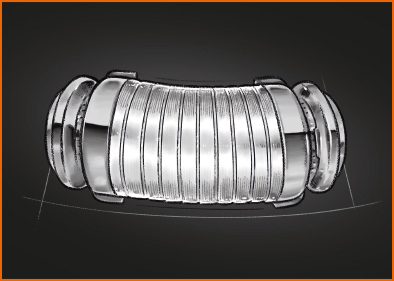

Tmax-Compensator Insulation for more efficiency

From the thermal viewpoint often the weak point in an otherwise finely-tuned exhaust system: compensators, hoses, and bellows. They eliminate the various axial and lateral forces between components within the exhaust system and can be found on nearly every engine. The challenge is to close these last gaps in the thermal system with flexible and high-performance elements.

Tmax-Compensator Insulations fulfil this function, can be integrated within the overall system, and can reduce temperature-loss in a sensitive system.

- Integrated into the complete system, full metallic encapsulation

- Increased safety and optimized efficiency due to the reduced temperature loss in sensitive systems

- High flexibility