Company Insight

Sponsored by Geographe

Addressing Premature Failures of Excavator Bushings in Asia

How often do you consider enhancing safety practices at your mine site?

Main image credit:

Precision and reliability are keystones for operational success in a demanding mining landscape. Every excavation project requires equipment that can withstand rigorous conditions and deliver consistent performance. Collaboration between global miners and suppliers such as Geographe, with extensive industry knowledge and cutting-edge facilities, allows for opportunities to enhance mining operations by developing high-quality solutions.

Since their expansion to Asia, Geographe has successfully implemented Enhanced Performance Parts (EP) that resulted from their collaboration with miners in different countries. One example is the Geographe EP Top Hat Bush – designed to solve premature failures of excavator bushings versus the original equipment manufacturer (OEM) designs.

Australian Solutions for Global Challenges

In 2010, Geographe partnered with an Australian contract miner to solve the issue of premature thrust plate failures of Hitachi Excavators.

In a standard Hitachi excavator bucket-stick arrangement, the bushes and thrust plates are separate components with various mine sites reporting the thrust plates as the weak link in this machine area.

Through in-house metallurgical analysis, Geographe determined that the OEM thrust plates were manufactured from a softer material than its surrounding components, leading to a faster wear rate. As wear occurs, the socket heads of the capscrews which secure the thrust plate in place, also become worn, eventually sheering off, causing dislodgement of the thrust plate and significant damage to bucket-stick mounting faces.

Some maintainers opted to weld the thrust plates into position, reducing the chance of the thrust plates becoming dislodged during operation. However, welding directly to the machine has the potential to compromise frame integrity and requires additional hot works during the fitment & removal procedure.

Increasing Asset Life of Excavators with the Geographe EP Top Hat Bush

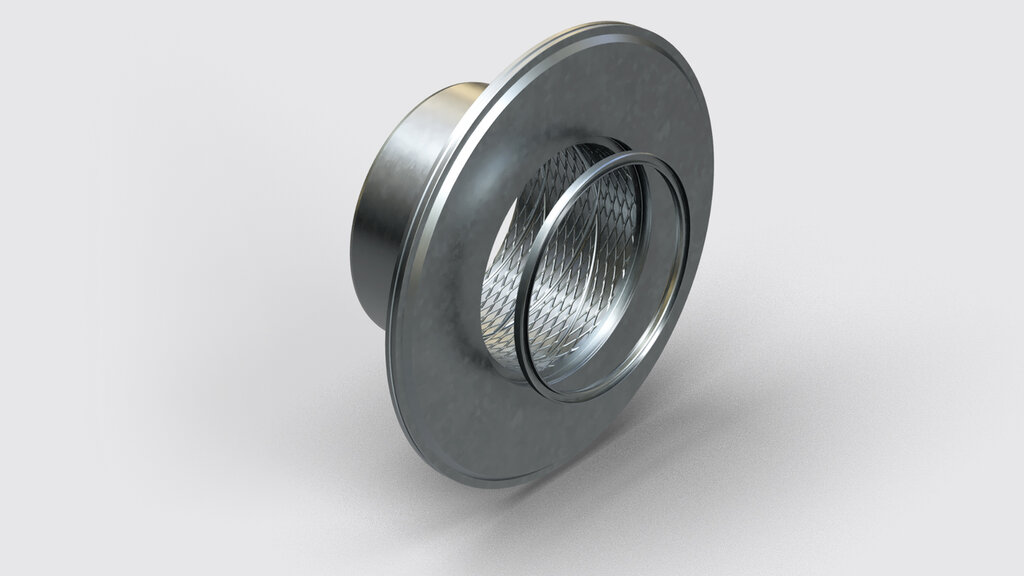

Unlike conventional OEM parts, the Geographe EP Top Hat Bush is manufactured from a single piece of improved material which has been gas carburised to ensure the stick-to-bucket tolerance remains at OEM specifications for longer periods.

With advanced lubrication techniques added such as figure 8 grease grooving and cross-hatching grease distribution methods, the Geographe EP Top Hat Bush provides superior lubrication to the pin for optimal performance.

Geographe EP Top Hat Bush

The incorporated split seal at the thrust face is changeable without disassembly to retain grease in the work zone. Fitting or removing this component does not require any modifications to the excavator or its accompanying components, as the EP Top Hat Bush is compatible with standard bore diameters, ensuring ease of fitment.

The Geographe EP Top Hat Bush for Hitachi Excavators mitigates premature wear, significantly reducing downtime, and allowing mining operations to run smoothly and efficiently.

Leveraging the success of the EP Top Hat Bush for Hitachi Excavators, Geographe has also implemented crucial upgrades for the Caterpillar 6020B Excavator. Deriving from the original Enhanced Performance Top Hat Bush design, this solution involved replacing standard bronze bushes with case-hardened steel, incorporating a larger thrust face to enhance contact surface area.

For us, machine up time is a priority. Once the thrust plates fail, we would normally swap out to a spare bucket to keep the machine running. The downside to this is some of our buckets are only achieving 60-75% of life before being sent to an offsite repairer. With the Geographe Top Hat bushes, we are now looking to extend our bucket change out period by an additional 2000-4000 hours.

Australian Tier1 Iron Ore Miner

Developing Parts to Enhance Mining Productivity and Reliability

Geographe’s Enhanced Performance parts have also been instrumental in preventing premature equipment failure in North-East Asia. Jansen Lie, International Customer Relationship Manager is bringing Geographe Enhanced Performance™ Parts and Geographe Specialised Tooling™ Solutions to the region and is available to discuss how the EP Top Hat Bush and other solutions developed to improve mine site productivity can address critical maintenance challenges and enhance your maintenance practices.

Book a chat with Jansen here.

Contact information

Geographe

480 Abernethy Road,

Kewdale WA 6105

Tel.: +61 8 9449 1111

Email: sales@geographe.com.au

Web: www.geographe.com.au