Efficiency increase:

Low NPSHr value of

compact rotary lobe pumps ensures

precise and reliable decantation of water

Until August 2017, two centrifugal pumps were used to decant a fine coal screen vacuum tank in an open-pit coal mine of a company in Australia. Since their high NPSHr value reduced the capacity of the plant, its management decided to replace both units with more efficient models.

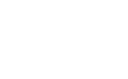

They chose two TORNADO® T1 rotary lobe pumps, which are manufactured by NETZSCH Pumps & Systems, Bavaria. These self-priming positive displacement pumps operate by two intermeshing rotors, transporting the conveyor medium continuously from the suction to the pressure side allowing accurate dosing.

Since they operate with a very low NPSHr, they are particularly well suited for the task in the Australian mine.

They are completely insensitive to the effects of cavitation, which may cause other types of pumps to fail at an early stage. The two VSD-driven units have been successfully employed since August 2017.

They ensure lower fluid levels in the vacuum receiver. Since the receiver can now be operated with a higher vacuum range at a more uniform level, the recovery rate of coal fines rises significantly.

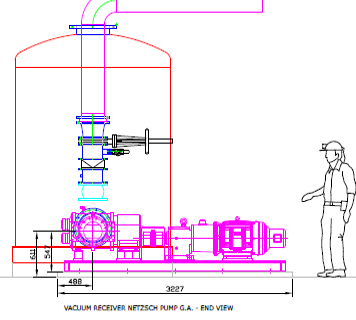

In an Australian open-pit mining, fine coal dust is extracted from water-coal dust mixture with a temperature of 25 °C.

"For this purpose, the mixture is first fed to horizontal belt filters," says Steve Weir, Business Development Manager at the NETZSCH Australia Pty Ltd subsidiary.

Thanks to gravity, water is collected in the transverse groove on the filter belt and fed into a vacuum chamber.

Liquid-ring pumps generate vacuum in the chamber by means of a sliding vane.

The vacuum draws the fluid from the belt filters into the vacuum tank.

Belt filters deliver water continuously, while the vacuum tank requires only a specific amount of water.

The excess liquid must be removed from the tank and be pumped on to the next process step. Until August 2017, two centrifugal pumps were used for decanting the excess water.

However, these pumps were not ideal. For example, they had a high NPSHr value, which meant that the intended flow rates could not be met with precision.

"Cavitations, or gas-filled bubbles, frequently develop in centrifugal pumps. They not only reduce the efficiency of the system, but make accurate dosing impossible", says Weir. "This, in turn, limited the throughput of the system."

The management, therefore, decided to replace the pumps with other models, which were expected to discharge process water with more precision, reliability and efficiency.

TORNADO® T1 pumps with

low NPSHr

The essential requirement for the new units was their suitability for pumping media containing solid matter. They also needed to feature flow rate of 240 m³/h, pressure of 3 bar, and NPSHr of 1.8 m.

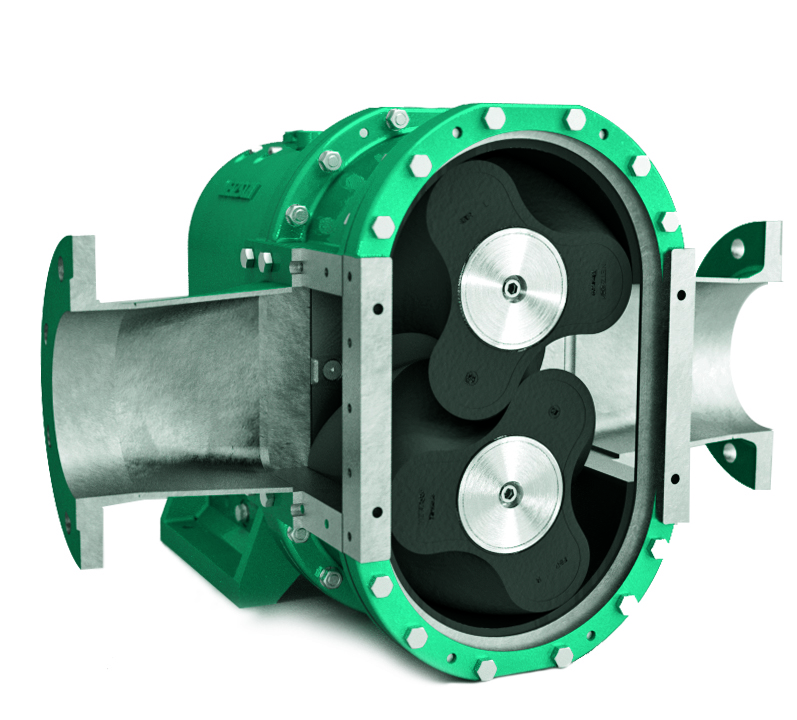

Finally, the management selected two rotary lobe pumps of the NETZSCH TORNADO® T1 series in size XLB-6/2. These pumps not only meet the requirements of the open-pit operator in terms of flow rate, pressure, delivery rate and suction; they also have exceptionally convenient dimensions.

"At first, we also considered NEMO® progressing cavity pumps," says Weir. "However, the client rejected these pumps, because they did not suit the spatial dimensions that are available on site.

" The key advantage of the two TORNADO® T1 models over the previous system is that the NETZSCH models are self-priming positive-displacement pumps, which guarantee continuous delivery. Inside the pumps, there are two intertwined rotors which are synchronized with one another.

The rotors create negative pressure on the suction side, which draws the medium to the rotary lobes without interruption. The lobes then convey the medium to the pressure side.

This conveying principle has a very positive effect when used in the relevant application. "The vacuum tank operates at a very low pressure, which in turn creates a very low inlet pressure for water intake from the vacuum tank," says Weir.

"Our pumps are well suited for this application, since they operate with a low NPSHr". They are, therefore, insensitive to the effects of cavitation which may cause other types of pumps to fail quickly. Furthermore, the volume transported depends on speed.

Thus, the desired quantity can be dosed easily by setting the rotations per minute. Depending on size, the pumps can achieve volumes of up to 1,000 m³/h.

When used in the mine in Australia, the speed is 218 rpm, and the conveyed volume is 240 m³/h. TORNADO® pumps can be used to smoothly transport almost any type of medium, from low-viscosity and high-viscosity fluids such as thixotropic or dilatant substances to sticky and non-sticky, shear-sensitive, or abrasive media.

The pump handles with ease even solid material up to 70 mm in size. When used in the decanting system, particle sizes are in the range of 0.5 mm, and fluid viscosity is 5 mPas.

Combustion engines, electric or hydraulic motors can be used as drives, depending on the requirements. In the case at hand, a 4-pole 45 kW motor is used.

Two TORNADO® T1 rotary lobe pumps, manufactured by NETZSCH Pumps & Systems in Waldkraiburg, Bavaria, decant a fine coal screen vacuum tank in an open-pit coal mine in Australia.

These self-priming pump systems operate via positive displacement, transporting the conveyor medium continuously from the suction to the pressure side using two intermeshing rotors.

High operational reliability and

simple handling

An essential feature of rotary lobe pumps from NETZSCH is that their gear and pump chambers are strictly separate from one another. This special Gearbox Security System (GSS) ensures that the medium cannot enter the complex gearbox, even in the event of the shaft seal failing.

This means high operational reliability. On the other hand, gear oil cannot enter the pump chamber. The seal is lubricated and cooled by means of easily accessible flushing and sealing water connections.

The design can be adapted to the specific application; for example, rotors with two to four lobes are available in various forms and materials, to suit the intended purpose. Rotary lobes with 3-blade helical geometry were selected for the water-coal dust mixture in order to ensure low pulsation.

The rotors are made of a particularly robust elastomer, which withstands the abrasive, solid-containing medium. Moreover, the pumps feature a modular housing structure with adjustable housing crescents, which ensure a long service life.

The units can optionally be equipped with replaceable wear liners, which are resistant to chemicals. Inlet and outlet nozzles were also specially adapted for use in the Australian open-pit mine.

Since they operate with a very low NPSHr, T1 pumps are particularly well suited for use in the Australian mine. They are completely insensitive to the effects of cavitation, which may cause other types of pumps to fail at an early stage.

The two VSD-driven units have been successfully employed since August 2017. They ensure lower fluid levels in the vacuum receiver. Since the receiver can now be operated with a higher vacuum range at a more uniform level, the recovery rate of coal fines was significantly increased.

Improved coal fines recovery

Since August 2017, the two TORNADO® T1 pumps have been employed to decant excess water from the vacuum tank, and to convey it to the clarifying or thickening tank.

Water is recovered there, and then reused in the coal treatment plant. The two VSD-driven XLB-6/2 units ensure stable and lower liquid level in the vacuum receiver, which can thus be operated with a larger vacuum chamber.

The vacuum for draining coal fines is thus more reliable. "Higher vacuum and more uniform vacuum level lead to more efficient recovery of coal fines," explains Weir.

In view of this result, the mine operator is very positive about the new rotary lobe pumps.

"We are very satisfied with the pump operation and the current performance of the plant," says a representative of the company. "This system has already paid for itself in the first three weeks of operation".

The company operates several coal mines in Australia, and plans to integrate NETZSCH decanting system into at least one further mine. They also plan to purchase a free-shaft TORNADO® T1 pump as a replacement pump.

Both units decant excess water from the vacuum tank and convey it to the clarifying or thickening tank. Water is recovered there, and then reused in the coal treatment plant.

For over 60 years, NETZSCH Pumps and Systems has served markets worldwide with NEMO® progressing cavity pumps, TORNADO® rotary lobe pumps, NOTOS® multi screw pumps, grinding machines, barrel emptying systems, dosing technology and accessories, providing customised, sophisticated solutions for applications in every type of industry.

With a workforce of over 2,000 and a turnover of more than 281 million euros (financial year 2019), NETZSCH Pumps & Systems is the largest business unit with the highest turnover in the NETZSCH Group, alongside NETZSCH Analysing & Testing and NETZSCH Grinding & Dispersing.

Author:

Roger Willis; Global Business Field Manager Chemical Pulp and Paper

CONTACT INFORMATION

NETZSCH Pumpen & Systeme GmbH

Geretsrieder Strasse 1

84478 Waldkraiburg

Germany

Phone: +49 8638 63-1020

Fax: +49 8638 63-2327