Effective Lubrication in the Mining Industry

To counter the risks associated with premature equipment failures that then lead to unplanned outages in mining equipment, it is now readily acknowledged that one, if not the most important area of maintenance are correct lubrication processes. Even a small reduction in the performance of the lubricant or a lube system will have a direct and almost immediate effect on the reliability of the mechanical asset in the field.

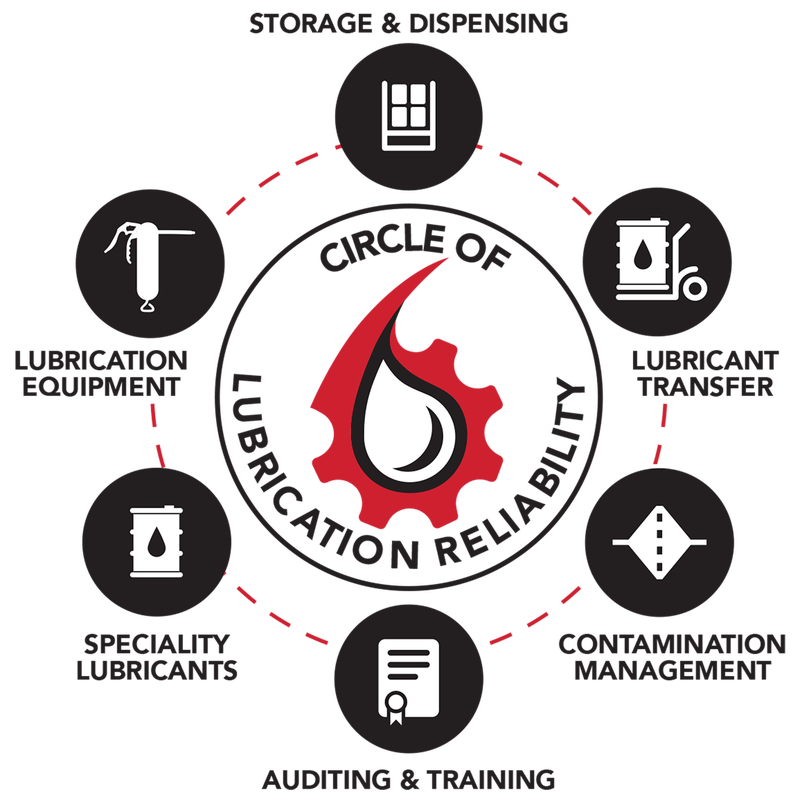

Lubrication Engineering Pty Ltd is the premier supplier of high performance lubrication equipment and specialised lubricants to the Australian market. We deliver maintenance solutions that improve equipment performance and ultimately increase business profitability. Lubrication Engineering protect your equipment by making sure the Right lubricant is in the Right place, at the Right time and in the Right quantity. This is achieved by working across all 6 areas of our ‘Circle of Lubrication Reliability’.

Videos

Case Studies

Almatek Mine Quarry

Open Gear System

+61 (0)2 9636 5655 | sales@lubeng.com.au | www.lubeng.com.au

Effective Lubrication in the Mining Industry

To counter the risks associated with premature equipment failures that then lead to unplanned outages in mining equipment, it is now readily acknowledged that one, if not the most important area of maintenance are correct lubrication processes. Even a small reduction in the performance of the lubricant or a lube system will have a direct and almost immediate effect on the reliability of the mechanical asset in the field.

Lubrication Engineering Pty Ltd is the premier supplier of high performance lubrication equipment and specialised lubricants to the Australian market. We deliver maintenance solutions that improve equipment performance and ultimately increase business profitability. Lubrication Engineering protect your equipment by making sure the Right lubricant is in the Right place, at the Right time and in the Right quantity. This is achieved by working across all 6 areas of our ‘Circle of Lubrication Reliability’.

Videos

Case Studies

+61 (0)2 9636 5655 | sales@lubeng.com.au | www.lubeng.com.au

+61 (0)2 9636 5655

Effective Lubrication in the Mining Industry

To counter the risks associated with premature equipment failures that then lead to unplanned outages in mining equipment, it is now readily acknowledged that one, if not the most important area of maintenance are correct lubrication processes. Even a small reduction in the performance of the lubricant or a lube system will have a direct and almost immediate effect on the reliability of the mechanical asset in the field.

Lubrication Engineering Pty Ltd is the premier supplier of high performance lubrication equipment and specialised lubricants to the Australian market. We deliver maintenance solutions that improve equipment performance and ultimately increase business profitability. Lubrication Engineering protect your equipment by making sure the Right lubricant is in the Right place, at the Right time and in the Right quantity. This is achieved by working across all 6 areas of our ‘Circle of Lubrication Reliability’.

STORAGE & DISPENSING

Storage & Dispensing

Storing lubricants correctly so that when they are dispensed, they are clean and dry is an ideal place to commence any lubrication improvement program. Ensuring each lubricant is clearly identified will also assist in making sure the right product is selected and dispensed, greatly reducing the risk of cross contamination.

The isoPOD family are purpose built, portable, plug & play, lubrication storage and dispensing systems designed specifically for dispensing lubricants from drums or IBC’s, either into Oil Safe transfer containers or directly into equipment. The choice is yours.

Read more

LUBRICANT TRANSFER

Lubricant Transfer

The transfer of lubricants from their stored container into the machinery asset can be technically & physically challenging but with the correct equipment and associated process, the right lubricant can be placed into service, clean and ready to use.

Putting the wrong grease over the top of an existing product in service can cause catastrophic failures. By managing the process, we ensure we have the right product going into the right location in a controlled and safe way.

At Lubrication Engineering we have the complete range of products and knowledge to help achieve the best possible outcomes.

Read more

CONTAMINATION MANAGEMENT

Contamination Management

Particulate and water contamination remain 2 of the most common reasons for premature lubricated equipment failures.

The smallest amount of particulate contamination, (much smaller than we can see with the naked eye) in the oil will lead to component wear, that will reduce the life of the equipment, causing unplanned outages and expensive repairs, decrease production and ultimately profitability.

Simple improvements can significantly reduce the risk of contamination related problems and Lubrication Engineering can show you how.

Read more

AUDITING & TESTING

Auditing both the lubrication process and equipment can provide important information that will help facilitate an agreed improvement program across all areas of the lubrication cycle.

The training provided by Lubrication Engineering provides real world, hands on knowledge that can be immediately applied by all lubrication and maintenance staff who attend the course. Based around the key aspects of our ‘Circle of Lubrication Reliability’ suer will be empowered to improve lube storage, transfer / top ups, oil sampling, cleanliness management, reduce waste, improve environmental outcomes and increase plant reliability.

Your investment in trained staff will encourage proactive lubrication management that will increase productivity while reducing the high costs associated with machinery breakdowns.

SPECIALTY LUBRICANTS

Specialty Lubricants

Not all lubricants are created equal and sometimes a problem child application can be improved simply by applying the correct lubricant.

Lubrication Engineering has been a proud distributor of LE Inc’s products in Australia and Papua New Guinea since the 1980’s. LE Inc’s high performance lubricants are made of highly refined, or synthetic base oils and proprietary additives. These enhanced lubricants far exceed the performance of conventional lubricants in a wide variety of industrial applications.

Read more

LUBRICATION EQUIPMENT

Lubrication Equipment

Lubrication Engineering has access to the most respected lubrication equipment brands from across the world. From grease guns to complex, dual line automatic grease systems and everything in between, we assist customers with the best possible solution to maintain the lubrication cycle on their equipment.

Read more

Videos

Case Studies

+61 (0)2 9636 5655

Storage & Dispensing

Storing lubricants correctly so that when they are dispensed, they are clean and dry is an ideal place to commence any lubrication improvement program. Ensuring each lubricant is clearly identified will also assist in making sure the right product is selected and dispensed, greatly reducing the risk of cross contamination.

The isoPOD family are purpose built, portable, plug & play, lubrication storage and dispensing systems designed specifically for dispensing lubricants from drums or IBC’s, either into Oil Safe transfer containers or directly into equipment. The choice is yours.

Read more

Lubricant Transfer

The transfer of lubricants from their stored container into the machinery asset can be technically & physically challenging but with the correct equipment and associated process, the right lubricant can be placed into service, clean and ready to use.

Putting the wrong grease over the top of an existing product in service can cause catastrophic failures. By managing the process, we ensure we have the right product going into the right location in a controlled and safe way.

At Lubrication Engineering we have the complete range of products and knowledge to help achieve the best possible outcomes.

Read more

Contamination Management

Particulate and water contamination remain 2 of the most common reasons for premature lubricated equipment failures.

The smallest amount of particulate contamination, (much smaller than we can see with the naked eye) in the oil will lead to component wear, that will reduce the life of the equipment, causing unplanned outages and expensive repairs, decrease production and ultimately profitability.

Simple improvements can significantly reduce the risk of contamination related problems and Lubrication Engineering can show you how.

Read more

Auditing & Training

Auditing both the lubrication process and equipment can provide important information that will help facilitate an agreed improvement program across all areas of the lubrication cycle.

The training provided by Lubrication Engineering provides real world, hands on knowledge that can be immediately applied by all lubrication and maintenance staff who attend the course. Based around the key aspects of our ‘Circle of Lubrication Reliability’ suer will be empowered to improve lube storage, transfer / top ups, oil sampling, cleanliness management, reduce waste, improve environmental outcomes and increase plant reliability.

Your investment in trained staff will encourage proactive lubrication management that will increase productivity while reducing the high costs associated with machinery breakdowns.

Read more

Specialty Lubricants

Not all lubricants are created equal and sometimes a problem child application can be improved simply by applying the correct lubricant.

Lubrication Engineering has been a proud distributor of LE Inc’s products in Australia and Papua New Guinea since the 1980’s. LE Inc’s high performance lubricants are made of highly refined, or synthetic base oils and proprietary additives. These enhanced lubricants far exceed the performance of conventional lubricants in a wide variety of industrial applications.

Read more

Lubrication Equipment

Lubrication Engineering has access to the most respected lubrication equipment brands from across the world. From grease guns to complex, dual line automatic grease systems and everything in between, we assist customers with the best possible solution to maintain the lubrication cycle on their equipment.

Read more