Collect with Carlson Instruments

Collect the data you need for a safe, efficient blast plan

Carlson Quarryman Pro Laser Scanner

- Extremely Rugged Laser Profile

- Does not Require Skilled Operator

- 250 Points Per Second

- Bench Models Generated in Minutes

- Sync to Carlson Command

Carlson BRx6 GNSS Receiver

- AthenaTM GNSS RTK engine

- Base or Rover on demand

- Integrated UHF radio

- Integrated GSM Modem

- Integrated Bluetooth & Wi-Fi

- IP67 Enclosure

Carlson Cabled and Rodded Boretrak System

- Cabled Boretrak lightweight, rugged and highly portable

- Rodded Boretrak: measures uphole and downhole deviation

- Audit drilling activity accurately

- Compare today’s results with historical data

- Easy-to-learn and operate

Execute with Carlson Machine Control

Execute blast plans with machine guidance

Bench Production Workflow

- Site control is setup utilizing the Carlson BRx6

- Carlson Quarryman Pro data is sent directly to Carlson Command

- Carlson Command creates a project blast pattern

- The blast pattern is pushed to Carlson Drill Grade for drill rig guidance

- Borehole deviation is analyzed with Carlson Boretrak before blasting

- Overall project monitoring and reporting is done in Carlson Command

Carlson Drill Grade Machine Guidance

- Operator drill pattern layout in field

- Navigate to hole more accurately

- Drill to elevation or depth with accuracy

- Drilling Logs sent remotely to Carlson Command in the Office

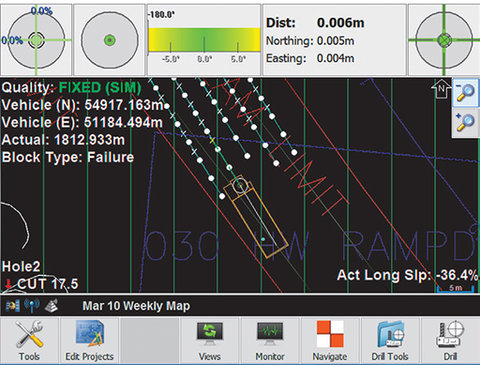

Plan View Navigation

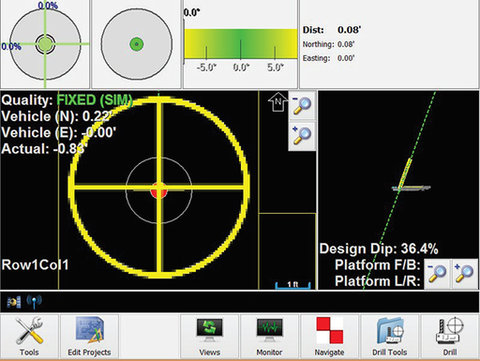

Hole Positioning

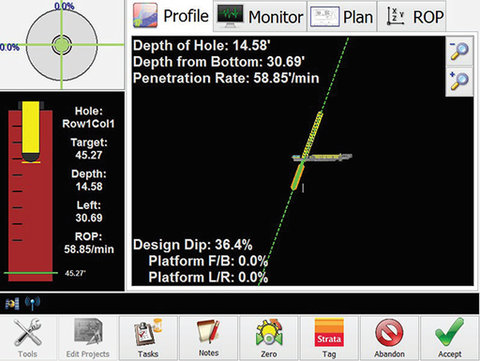

Drill Screen

Execute blast plans with machine guidance

Bench Production Workflow

- Site control is setup utilizing the Carlson BRx6

- Carlson Quarryman Pro data is sent directly to Carlson Command

- Carlson Command creates a project blast pattern

- The blast pattern is pushed to Carlson Drill Grade for drill rig guidance

- Borehole deviation is analyzed with Carlson Boretrak before blasting

- Overall project monitoring and reporting is done in Carlson Command

Carlson Drill Grade Machine Guidance

- Operator drill pattern layout in field

- Navigate to hole more accurately

- Drill to elevation or depth with accuracy

- Drilling Logs sent remotely to Carlson Command in the Office

Execute with Carlson Machine Control

Plan & Report with Carlson Software

Bring it all together with cloud-based software

Carlson Command Data Storage and Control Software

Powerful Management & Reporting

- Individual Machine Volume Metrics

- Drill Metrics

- Time & Drill Reporting

- Productivity Analysis

- Blast Pattern Layout Tools

- Historical Replay

Dynamic Productivity Tools

- On-the-move data exchange (machine to machine)

- Surface updating

- In-cab monitoring

- Tasks & delays/down-codes

- On-site proximity warnings

- Avoidance zones, and more

Contact us

Carlson Software Inc

33 East Second Street

Maysville, KY 41056 USA

T: +1 800-942-2540