IN FOCUS Excellence Awards

Sponsored by Nuton

Mining Technology Excellence Awards 2025: Nuton

Copper inspired by nature and powered by innovation: Nuton’s Partner-First Model to Close the Copper Gap

Main image: An NH90 TTH of the Royal New Zealand Air Force. Credit: Gordon Arthur

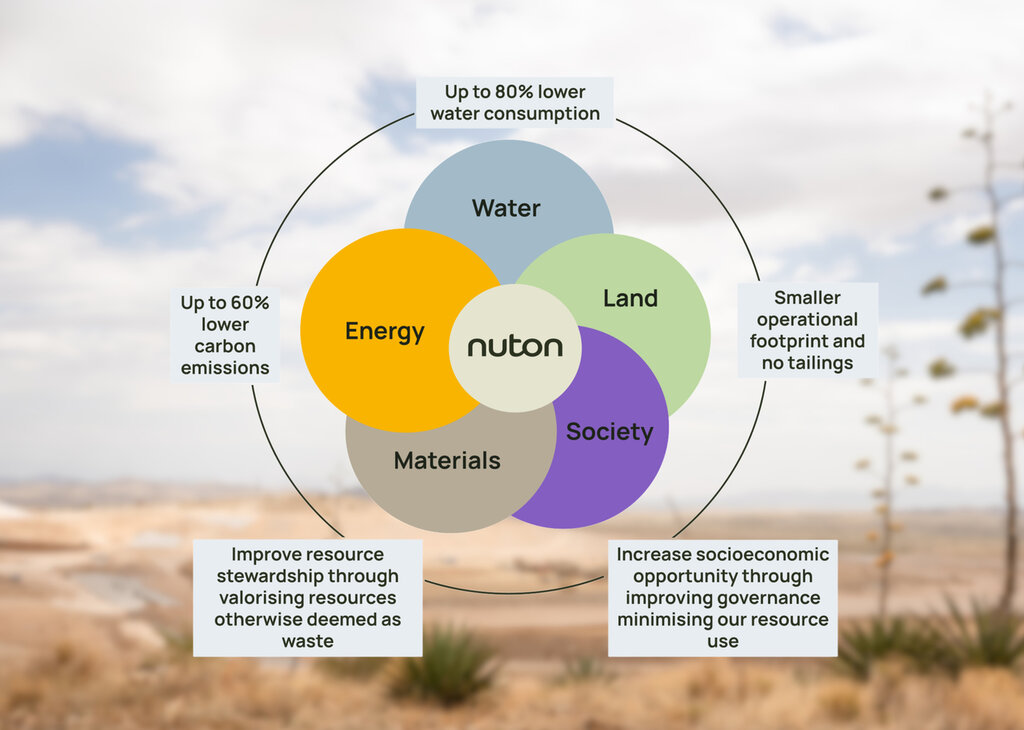

Nuton CEO Adam Burley details a partner-first, modular approach to copper that delivers site-ready cathode with up to 80% less water and up to 60% lower emissions—closing the supply gap for electrification while lifting ESG standards.

Adam Burley, CEO, Nuton

With market leading recoveries and ISO verified transparency, the Nuton® Technology aims to replicate success through a data driven, “learn by doing” model.

Nuton won three awards in the 2025 Mining Technology Excellence Awards.

Mining Technology: Nuton has been recognized for transforming copper production. How does your long‑term vision align with industry needs and the energy transition?

Adam Burley: The world needs more copper—and better ways of producing it. As electrification scales, demand for the metal is surging across grids, transport, and industry. Our focus is unlocking copper from ores that are traditionally hard to process, while cutting water use by up to 80% and emissions by up to 60% versus conventional routes. We eliminate concentrators and tailings dams and produce cathode on site, -shortening the supply chain from mine to metal and shortcutting logistics risks. We’re achieving up to 85% copper recoveries. Our integrated approach—technology, sustainability, and disciplined growth—offers a blueprint to close the supply gap responsibly.

Mining Technology: What in Nuton’s culture and leadership has driven rapid growth?

Adam Burley: We’re united by a mission to “do copper differently.” That shared purpose, coupled with a startup‑like agility, has accelerated progress. Our team blends visionaries and specialists—scientists, strategists, builders, and operators. We learn by doing: start, iterate fast, and share lessons. We don’t talk about mistakes; we talk about learning and improving. Leadership keeps objectives clear, feedback timely, and decisions data‑driven. We also treat innovation as a team sport, empowering people to solve problems and keep momentum. Openness to collaborate—inside and outside Nuton—has been essential.

Mining Technology: Beyond the bioleaching, what other innovations mattered most?

Adam Burley: Our delivery model. We enable partners to deploy and operate the technology rather than running it ourselves. That means designing a continuous, scalable process that’s safe, efficient, and maintainable; preparing sites for operational readiness; and supporting performance optimization. Nuton’s delivery model is not a point transaction, it is a process that relies on true partnership with the site owner, from testing and engineering to construction and commissioning. Through the protocols and tools of our delivery model, our partners and ourselves have the confidence that the technology is built with efficiency and integrity. Designing a reliable delivery model is central for Nuton to capture the huge market opportunity in front of us.

Caption. Credit:

Mining Technology: What are you hearing from customers and stakeholders?

Adam Burley: Buyers want verified low‑impact copper. We act as a systems integrator—bringing biology, chemistry, digital, and commercial together—to deliver the lowest‑impact copper economically, tailored to ore and site conditions. We prioritize downstream partnerships that value high environmental and social credentials, not just transactions. Carbon is the loudest market signal today, but we go further through our Positive Impact pillars: water, energy, land, materials, and society. We meet today’s needs while nudging demand toward broader sustainability metrics.

Mining Technology: How do you choose partners and ensure mutual value?

Adam Burley: Strategic alignment, technical feasibility, and shared ESG values are non‑negotiable. Ideal partners own greenfield, brownfield, or legacy sites with ores that challenge conventional processing. Early on, we built a diverse portfolio of use cases to refine the type of asset where Nuton adds the most value. We use a staged evaluation for commercial and technical viability before deployment. Partners typically provide site access, permitting, and local know‑how. We bring the tailored technology package, metallurgical testing, and ESG guidance. Both sides share in the uplift. We modularize the technology to speed replication across scales and geographies.

Caption. Credit:

Mining Technology: How do you ensure adaptability across different ore bodies and sites?

Adam Burley: A modular technology package defines the core engineering, equipment, and flowsheet, with flexibility for local conditions. The package remains consistent across greenfield, brownfield, and legacy sites. Before deployment, we run a rigorous suitability assessment, using predictive tools to evaluate technical, financial, and ESG performance. We analyze ore chemistry and physical properties, model outcomes, and validate with test work. This de‑risks deployment and maximizes effectiveness.

Mining Technology: What were the biggest scale‑up challenges, and how did you reach commercial readiness?

Adam Burley: Translating lab‑based R&D into industrial-level performance is the core challenge. We addressed it by engineering a continuous, scalable, maintainable process, and by enabling partners to run it. Our flagship scale‑up with Gunnison Copper at Johnson Camp Mine, Arizona, shows the model in action. With existing SX‑EW capacity, a permit‑ready leach pad, and a committed partner, we moved from concept to cathode in under two years. We’re currently producing copper via ROM leaching and are commissioning the Nuton circuit for first Nuton copper production in the coming weeks. We consciously limited study scope to move faster, captured more than 100 learnings, and rolled them into our commercial package. It’s about bringing Nuton to market as a scalable, partner‑driven solution—not just a technology.

Caption. Credit:

Mining Technology: How are you attracting and developing talent as the team scales?

Adam Burley: Purpose is a magnet. We’re tackling a pressing global challenge, and people want to be part of it. We combine startup agility with Rio Tinto’s resources. We present Nuton as an innovation company, not just a mining tech provider, which resonates with engineers and scientists. We foster a growth mindset and continuous experimentation; every project is a chance to improve. We invest in cross‑functional development so teams can blend technical, environmental, and commercial skills.

Mining Technology: What risks matter most as you deploy globally?

Adam Burley: Performance at scale and in the real world. Our stepwise scale‑up—including Johnson Camp Mine—was designed to validate design, delivery, and performance. Construction is complete and commissioning is well advanced. We’ll crystallize the learnings from this deployment into our commercial “lego brick” for replication across the portfolio. That’s how we manage uncertainty while moving at pace.

Caption. Credit:

Mining Technology: What differentiates Nuton from other copper extraction technologies?

Adam Burley: Market‑leading recovery and leach kinetics, plus the breadth of our toolbox. We integrate microbiology, chemistry, thermodynamics, and data analytics into one optimized process, with the optionality to deploy different tools as needed. Our partner‑driven delivery model offers a lower‑capital alternative to concentrators and accelerates scaling. Decades of R&D underpin a predictive, data‑rich foundation that lets us forecast outcomes by site. That precision helps maximize value and minimize impact. Sustainability is embedded via Positive Impact—we aim to give more than we take and set higher standards through innovation and collaboration.

Mining Technology: How do you embed ESG into day‑to‑day decisions?

Adam Burley: We integrate sustainability from commercial agreements to financial modelling and partner selection. We strive to deliver the lightest‑footprint copper and Positive Impact in at least one pillar on every deployment. Business cases include carbon and water metrics alongside financials. We also help partners strengthen their ESG practices and align with benchmarks.

Mining Technology: How do you ensure transparency and credibility in reporting?

Adam Burley: We commit to rigorous measurement and radical transparency. Pre‑operational LCAs set expectations across the five Positive Impact pillars. Real‑time sensor data will be gathered and set against those expectations, showing progress and gaps. We track Positive Impact at the venture level and via site‑specific LCAs at the product level. Our LCAs comply with ISO 14040/14044 and are peer‑reviewed and independently verified. We share the path to reduction—not just the wins.

Mining Technology: How are you collaborating across the ecosystem?

Adam Burley: We leverage internal expertise and a global network of external experts. Rio Tinto’s Innovation Advisory Committee—independent entrepreneurs, scientists, and innovators—helps us stress‑test ideas. From day one, we embedded Positive Impact into partner engagements, including with juniors. We aim to lift industry standards through co‑solving, not just information sharing.

Mining Technology: What’s next—technologically and strategically?

Adam Burley: Technologically, we’re expanding into recovery of additional metals and improving unit operations. Digitally, we’re integrating decades of data into a platform—supported by AI—to drive further performance and delivery efficiencies. Strategically, we’ll keep a clear focus while preserving optionality to meet changing partner, customer, and shareholder needs.

Caption. Credit:

Mining Technology: And the legacy?

Adam Burley: Positive Impact defines it. We want to move beyond “zero harm” to regeneration and lasting benefits—showing mining can be a force for good and reshaping the industry’s license to operate.

Mining Technology: Any advice for peers?

Adam Burley: Partner deeply. Embed sustainability from the start. Be radically transparent about goals, progress, and challenges. Welcome failure as a learning tool.

Adam, thanks for showing how “doing copper differently” can scale low impact supply at pace. We’ll be watching first Nuton copper from Johnson Camp Mine and the rollout of your commercial “lego brick” as Positive Impact sets a higher bar for the industry.

Contact information

Nuton

1 Research Avenue,

Bundoora,

Victoria, 3083,

Australia

Email: nuton@riotinto.com

Web: www.nuton.tech

- Biffa internal savings data, average saving (January - August 2023)

- Nisbets internal savings data, average saving (January – September 2023)

- Compliance365 internal data, average savings

- HEINEKEN UK data, Calculations based on SmartDispense® active accounts each year since 2015 with 10 lines

- Independent test results based on subterranean and ground floor pub cellars of varying sizes

- Independent test results based on subterranean and ground floor pub cellars of varying sizes