Q&A

Through the hourglass: Propeller Aero on sand mining

JP Casey speaks to Richie Hadfield of Propeller Aero about the challenges facing sand miners, and how drones can aid in the mining of this key mineral.

S

and is, without exaggeration, one of the building blocks of human development on Earth. With around 40 billion metric tons of sand used a year, making the grainy material the second-most consumed raw material on the planet after only water, humanity is starting to feel the effects of its insatiable desire for sand.

While the world does not yet face an acute shortage of sand, this appetite shows no signs of abating. With sand a fundamental part of urbanisation and construction developments, demand for sand is only set to increase, bringing unique challenges for the mining industry.

We speak to Richie Hadfield, head of product at drone mapping firm Propeller Aero, about the challenges facing sand miners, and the role that drones could have in the exploration and extraction of this vital resource.

JP Casey: Why are the world’s sand reserves starting to dwindle, and what impact could this have?

Richie Hadfield: Sand is the world’s most consumed raw material after water. Over the last two decades, the use of materials such as sand, gravel and aggregates has tripled, reaching between 40 and 50 billion metric tons a year. This has led to a global shortage that the United Nations considers to be one of the greatest sustainability challenges of the 21st century.

A variety of factors – including increased demand for urbanisation, population growth and infrastructure trends – have contributed to this sand shortage, and it has been further exacerbated by rising sea levels and coastal flooding due to climate change.

Sand is a key material used on construction sites and infrastructure projects, as it is used to build roads, bridges, high-speed train corridors and more. Sand from deserts cannot be sourced for construction use, as the grains are too small, so the construction industry sources sand from three main places: river sand, pit sand – which is obtained by digging deep pits – and crushed sand, which is created by crushing rock to fine particles.

Are sand reserves subject to the same regulations as mineral resources? What impacts has this had on sand reserves?

Although the sand shortage may not be front and centre on everybody’s radar, it’s important to get ahead of it … which will ensure the extraction and movement of sand is not wasting any of the resource. Sand mining is mostly regulated in the North America, but on other continents such as Asia and Africa, the commodity is largely unregulated or under-regulated.

Sand is often extracted illegally from coastal areas, making it difficult to mitigate depletion in some places. The UN has called for global regulations to come into effect before the resource is exhausted. This would result in industry members looking at sand in the same way they do other valuable resources like water.

What are some of the environmental consequences of sand mining, and how can some of the more destructive impacts be mitigated?

Irresponsible sand mining can contribute to coastal erosion and long-term damage to the planet. Site managers should ensure compliance with all local regulations, considering every aspect of an operation and how it affects the environment. It is also important to create productive and collaborative relationships across the communities in which [employees] are working. Workplace health and safety, as well as the health and safety of the surrounding communities, should always be a priority.

Construction companies can ensure they are using sand that is being mined responsibly and sustainably on their worksites, as well as supporting local organisations working to combat coastal erosion. Worksites can accurately measure their sand stockpiles to ensure they are not wasting any of the resource.

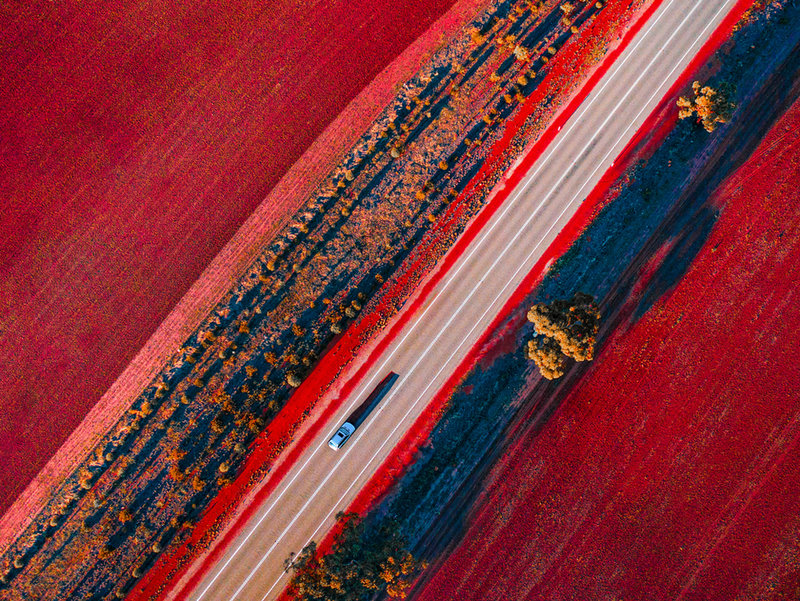

// Main image: 3D System Model and Completed Installation. Credit: Deimos

How can advanced technologies such as drones be used to help minimise the loss of sand reserves?

Advanced technologies can help accurately and efficiently survey sand stockpiles and efficiently move sand to minimise the loss of reserves. For example, drone surveys create highly accurate 3D maps of worksites at any stage of the project, gathering data in near real-time.

The more frequently and accurately that stockpiles are surveyed, the better-informed site workers are through every step of the project. Interactive 3D maps can be used to track progress, measure volume and improve collaboration across the team. This contributes to more sustainable mining and retention of resources because it leads to accurate estimates, informed decisions and effective communication.

Attaching sensors to earthworks equipment also allows for near real-time estimates of grade, elevation and volume. This leads to improved precision in the use, extraction and movement of sand.

Advanced technology, such as drone surveying, plays a part in addressing other sustainability challenges. It empowers people with insight to protect surrounding ecosystems, landmarks and waterways, as well as reducing energy consumption and greenhouse gas emissions.

Is there anything the sand mining industry could learn from other mining sectors?

Many organisations in the mining and construction sectors have begun to take on an accelerated purpose, which is an ongoing commitment to sustainability to make a positive impact on communities and the environment. Many have committed to new ESG goals, created workplace safety initiatives and prioritised the safety and environment of the communities they are working in.

The sand mining industry can take on this same commitment, and work to only partake in sustainable sand mining with a commitment to only use ethically sourced sand. It’s important to look at a worksite as a whole and make decisions in the best interest of the environment and community. Focusing emerging technology on sustainability goals can not only win over communities and key stakeholders, but also accelerate a business’s growth.