Duratray is part of Conymet International Group, with more than 40 years of experience in the mining industry. They specialise in the design, engineering, manufacturing and commercialisation of dump bodies for haulage equipment. Along with spare parts, steel and rubber wear components they provide technical assistance, maintenance and replacement of parts.

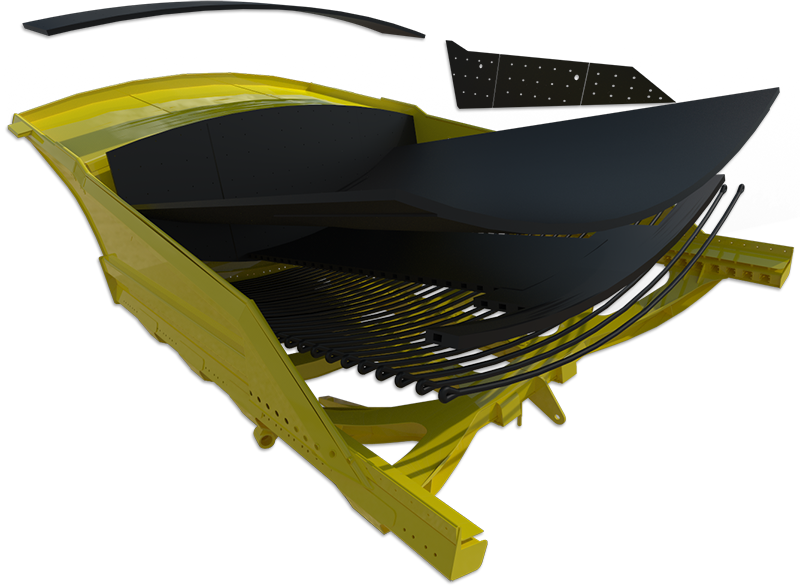

Their staple product, the Duratray Suspended Dump Body (SDB), is a unique lightweight tray that consists of a flexible rubber wear mat supported by high capacity synthetic suspension ropes and a steel frame resistant to abrasion. This design has demonstrated a wide range of benefits catered to specific mine applications including increasing payload, combating carry-back and reducing noise.

Over the last 10 years a vast number of innovative engineering improvements have been undertaken on the Duratray SDBs, consisting of developments to suit most standard mining conditions including heavy or abrasive rock and sticky materials.

Continue

International

Continue

Invested

Duratray International is committed to reducing the environmental impact within the industry and achieved major success through its custom Suspended Dump Bodies. The company has undertaken various operations that reduced linear and weighted sound levels by up to 10dB on haul trucks while increase truck lifespan and productivity – successfully achieved in the Hunter Valley with Yancoal.

While the unique design of the SDB system decreases noise levels, making it suitable for mines operating near urban areas, it reduces carry-back and offers high efficiency. This technology is leading the way in innovation and sustainability including an association with the first lithium powered truck.

The technology and innovation found in the Duratray SDB will provide an excellent complementary edge for the project’s ambitions to become a carbon-footprint

reducing, low-noise, economically friendly industrial EV, or, as Duratray call it, “a whole green truck”.

Top

case study

Moolarben

Coal Mine

Scroll down to read the case study

+

Watch the video for this case study

“

Not only did the new bodies reduce loading noises by up to 10 decibels, but it was found that payloads were also increased, improving productivity and efficiency at the mine.

www.duratray.com

Moolarben Coal, located 45 kms north-east of Mudgee, operating since 2013 knew from early in the development phase that minimising noise impacts is an important part of the mine’s profile. The company were operating within noise compliancy conditions but continued community feedback prompted further research into ways to improve the levels of noise coming from the mine.

Moolarben sent its employees into the community at night to assess. Following that investigation they came up with the key source of concern with banging and crashing noises which was the first pass loading activities. At this point Moolarben Coal Mine were complying easily with the conditions but due to the community feedback thought – what can we do about this?

To this end the company teamed up with Komatsu and Duratray to implement a solution for its 220 tonne truck fleet that would help to reduce noise impacts. Duratray provided Moolarben with a specific design body which reduced loading noise while still maintaining truck efficiency. Unlike regular truck bodies, Duratray’s suspended dump body is designed to reduce loading noise, with all trucks fitted with non-standard sound attenuated kits provided by Komatsu.

Not only did the new bodies reduce loading noises by up to 10 decibels, but it was found that payloads were also increased, improving productivity and efficiency at the mine. The bodies are able to carry 20-27 metric tonnes more than the mine was producing before, reduced vibration jarring for the operator and reduced spillages.

The initial Suspended Dump Body trial successfully delivered a notable measurable benefit of noise reduction during loading of adverse hard rock materials and with the success of the first trial the company invested into four new SBDs to fit the fleet of Komastu haul trucks.

A spokesman for the NSW Minerals Councils said the investments being implemented at Moolarben to help ease community concerns around mining showed the ways in which mining companies were listening and responding to concerns.

At the time, Moolarben Coal’s Stealth Fleet was recognised for its environmental excellence at a NSW Minerals Council’s awards ceremony. The initiative won them a finalists position, placing them highly commended at the Community and Environment Excellence Awards. This investment by Moolarben Coal was seen as setting a new industry benchmark for environmental noise reduction impacts on the community.