QUALITY WEAR-RESISTANT

CERAMIC LINING SYSTEMS

The lowest cost per processed ton compared

to any alternative lining materials.

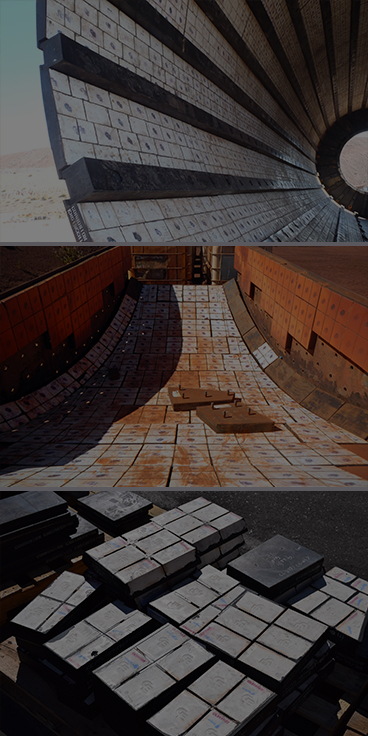

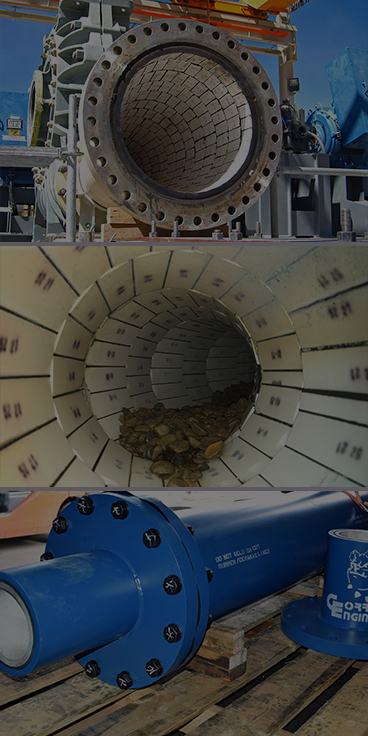

CORROCUBE

Exceptional impact and abrasion

resistance to large, coarse material

CorroCube

Wear lining system consisting of premium ceramic cubes molded in impact-resistant rubber

Product Details

CorroCube is a high performance abrasion and impact resisting lining system that features proprietary cube-shaped ceramic elements molded in a matrix of premium, tear and wear resistant, energy absorbing rubber. Corrosion Engineering’s exclusive bonding system ensures that the ceramic cubes do not disbond from the rubber, ensuring long and effective liner life. Several ceramic formulations are available depending on the application. In extreme applications, CorroCube liners can be installed in a matrix of abrasion resistant (A/R) steel plate (up to 500BHN) to provide structural support for the ceramic/rubber matrix, and provide exceptional wear life where competing products cannot. For applications with high impact and sticky materials, CorroCubes can be incorporated into the surface of Corrosion Engineering’s dynamic inflatable liner to form an exceptionally wear-resistant, yet flexible and dynamic, wear surface.

Applications

High-impact, high-pressure applications in which ceramic tile may not have sufficient structural resistance, and high-performance rubber may not offer the required wear life. CorroCube liners are ideal for impact plates, feed and discharge chutes, transfer chutes, coarse ore feeders, wear bars, dead bed bars, screen feed and distribution chutes, slurry boxes and launders, and skirt board liners.

CORROTILE

Superior wear-resistance in extremely

abrasive sliding applications

CORROTILE

Wear lining system consisting of premium ceramic tiles molded in impact-resistant rubber

Product Details

CorroTile is the economical ceramic lining alternative for applications with sliding abrasion and moderate-to-heavy impact. The smooth tile surface reduces the tendency of materials to adhere to the chute wall, and the ceramic polishes overtime to a glass-smooth surface. Depending on the application, Corrosion Engineering application specialists can select from a variety of ceramic compositions to match the needs of the application. CorroTile is bonded to the steel backing plate using high quality, tear and abrasion resistant, energy absorbing rubber. The use of rubber, compared to other bonding materials, reduces possible fracture of the ceramic under impact.

Applications

CorroTile liners are ideal for applications where a smooth, high performance, versatile and economical, long lasting protection system. These include Feed and Discharge Chutes, skirt board liners, sump linings, slurry boxes and launders, and locations where there is high velocity sliding abrasion.

SLURRY PIPE

Engineered abrasion and corrosion

resistance for aggressive slurries

SLURRY PIPE

Rubber and rubber/ceramic-lined slurry pipes including fittings, elbows, reducers and spools

Product Details

Corrosion Engineering manufactures rubber and rubber/ceramic lined slurry pipe for your most difficult applications. Rubber lining is the material of choice for the majority of applications, and Corrosion Engineering can offer a variety of natural and synthetic rubbers to suit the application and chemical environment. However, when the duty is severe, and system availability is critical, the natural choice is one of Corrosion Engineering’s ceramic lined slurry pipe options. We offer two different types of linings, traditional ceramic tile in thicknesses of 12-mm and 25-mm, and Corrosion Engineering’s exclusive SuperPipe system that utilizes sleeves of Isostatically pressed and fired alumina ceramic secured inside the pipe using a matrix of expanding rubber. SuperPipe offers a hydraulically smooth inner surface with excellent sleeve-to-sleeve concentricity to minimize turbulence, power requirements and wear. Corrosion Engineering’s Application Engineers can select from several ceramic compositions to ensure optimum performance in your particular application.

Applications

Tailings, cyclone feed pump suction and discharge, ball mill feed spouts, coarse slurries that require high transport velocity, choke station piping systems, high velocity gravity slurry lines.

VIBRACUBE

Eliminate material build-up and minimize

maintenance in sticky transfer applications

VIBRACUBE

Patented rubber and ceramic-reinforced dynamic inflatable lining system

Product Details

Corrosion Engineering’s VibraCube dynamic lining systems are the solution to extremely abrasive materials that are also sticky. The VibraCube liner features Corrosion Engineering ceramic cubes molded into the face of a dynamic inflatable liner. The combination of the smooth surface of the ceramic, Corrosion Engineering’s Moly Rubber, and the pulsing of the dynamic control system as the liner inflates, assures smooth, non-sticking flow of even the most difficult clays and other sticky materials. As with the CorroCube system, Corrosion Engineering’s application specialists can select from a variety of ceramic and rubber compounds for optimum performance in your unique application.

Applications

Transfer chutes, feed and discharge Chutes, Screen Discharge chutes.

CONTACT US

P.O. Box 5670

Mesa, Arizona 85211

Ph: +1 (480) 890-0203

Fax: +1 (480) 890-0589