Company Insight

Sponsored by Geographe

Geographe's Solution-Based Approach with Enhanced Performance (EP™) Parts

Click to edit...

Main image credit:

Geographe, a solution-based innovator, has consistently prioritised product evolution and improvement over imitation. Since its inception, Geographe has been dedicated to providing the mining industry with Enhanced Performance parts that address the unique challenges faced by miners. With a comprehensive understanding that different commodities impact equipment in varying ways, Geographe has developed a range of specialised products and tools to optimise asset performance. Geographe's solution-based approach utilising Enhanced Performance has helped mine sites overcome challenges and achieve greater safety and productivity.

Caption. Credit:

Tailored Solutions for Diverse Mining Environments:

Geographe understands that machines operating in different mining environments have unique requirements due to varying factors such as the nature of the commodity and working conditions. To accommodate individual mine site needs, Geographe actively engages and collaborates with customers to ensure parts are effective, commercially viable and engineered to exceed expectations.

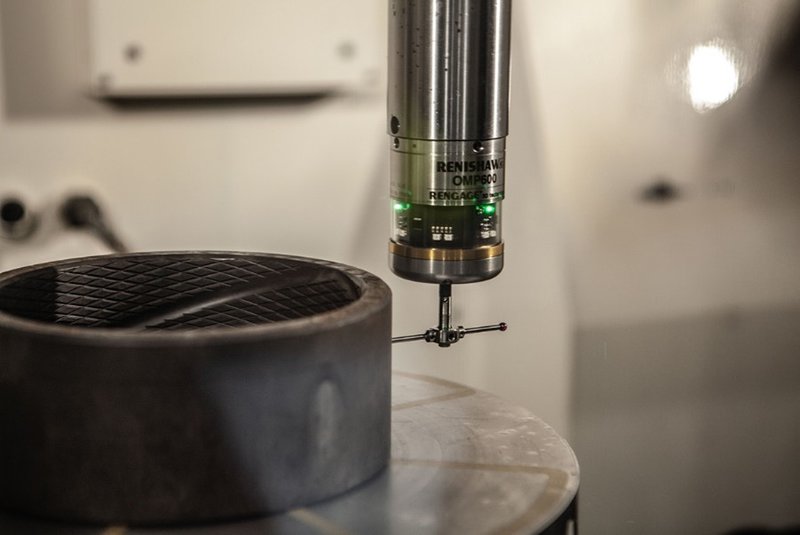

To guarantee product accuracy and completeness, Geographe has an independent, climate-controlled inspection room where all manufactured parts undergo rigorous statistical inspection against drawing specifications and process dependencies. Employing cutting-edge digital measuring equipment with Bluetooth connectivity, Geographe automates inspection reports while conducting part inspections, ensuring efficient and accurate reporting.

Geographe also enables customers to have visibility of the quality of the products they receive to suit their specific mine site requirements by creating complete traceability of the parts.

Caption. Credit:

Holistic Approach to Asset Optimisation:

Geographe's commitment to Asset Optimisation extends beyond individual components. The company takes a holistic approach to maintenance practices through its Product, Innovation & Development Services Team, closely collaborating with customers and observing maintenance tasks firsthand to gain a comprehensive understanding of the desired outcomes and the actual processes involved. By aligning with safe work procedures and incorporating frontline workers' ideas and suggestions, Geographe develops user-friendly solutions that prioritise both safety and productivity.

This collaborative approach has proven highly effective in identifying and resolving maintenance challenges such as difficult, time-consuming ball stud removals. Geographe collaborated with Fortescue Metals Group (FMG) to discover a safer and less labour-intensive solution, creating the Ball Stud Removal Tool (BSRT). This innovative solution is lightweight for single-person operation, can be used in field breakdown situations, and is compact enough to be stored in a small, wheeled carry case. Geographe's approach to collaborative innovation was recognised by the BSRT being awarded the 2021 Innovative Mining Solution Award at the annual Australian Mining Prospect Awards.

Caption. Credit:

Eliminating Thermal Lancing with the incorporation of the Colleted Pin Assembly (CPA):

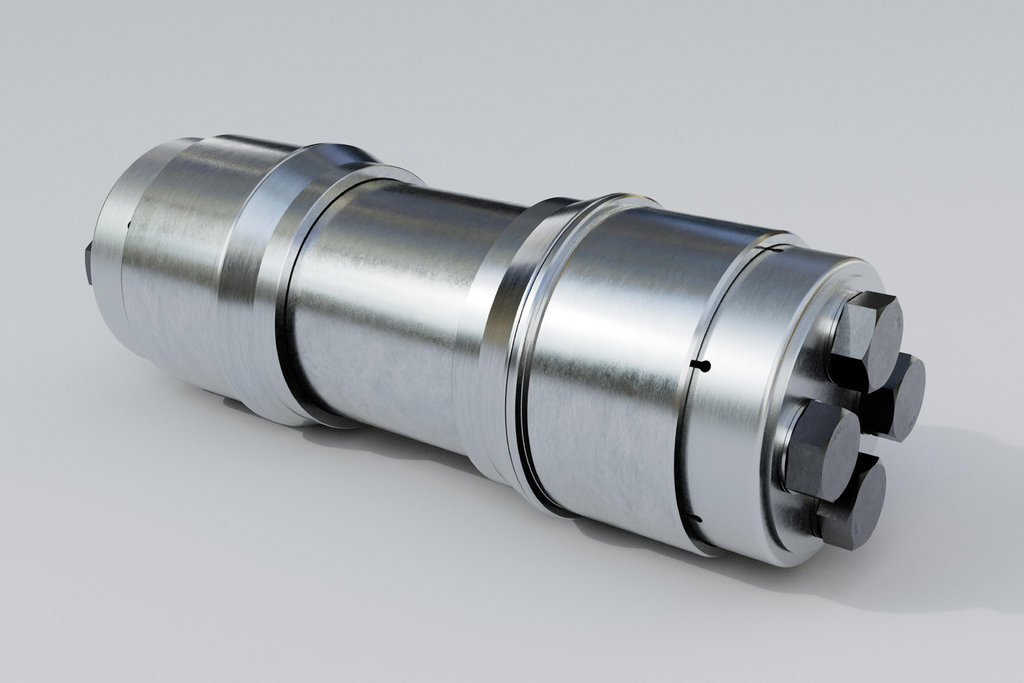

One significant challenge in maintenance is the reliance on high-risk practices such as hot works and thermal lancing. Geographe recognised the hazards associated with these practices and initiated the Elimination of Hot Works and Thermal Lancing Project in 2019. Through engagement with miners across Australia, Geographe identified the need for safer alternatives to remove seized or stuck components. Thermal lancing exposes workers to risks such as lung damage, asthma, hearing loss, and extreme heat exposure. In response, Geographe developed the Collated Pin Assembly (CPA), which eliminates the need for thermal lancing by addressing the root cause of the seizure.

The CPA incorporates a tapered collet system that creates a self-wedging effect between the pin and frame bores, effectively eliminating pin seizures. The CPA offers a safer and more efficient alternative to thermal lancing by fundamentally changing how the component is retained in position. Geographe conducted successful trials of the CPA on an active mine site, with the assembly operating flawlessly for over 12,000 hours. Based on these positive results, Geographe further optimised the product and developed an installation & removal tooling kit specifically tailored to Komatsu 830e haul trucks.

Caption. Credit:

Continuing the Path of Innovation:

Geographe's manufacturing facility in Bunbury is achieving numerous world-firsts by implementing an integrated work system that enhances in-house efficiency and reduces product lead times to their customers.

Enhancing efficiency with the co-existence of robotic arms with automated machines such as the Okuma Multus U5000 multitasking machine centre, featuring a Twin Spindle & Turret configuration, the most complex robot integration on a Multus in Australia. The Multus U5000 offers an all-in-one capability that can produce complex machined components within a 24/7 continuous manufacturing operation.

In addition, Geographe also installed a DMG Mori Vertical Grinding Machine, which comes with a fully automated robotic cell for 24/7 operation and is the first of its kind in Australia. They then installed a second machine to work in tandem with the first machine, doubling the output with the same automation infrastructure.

Geographe’s innovative approach to manufacturing has set new standards for component supply into the METS industry Continuing to listen to the customer's needs to develop Enhanced Performance parts & Specialised Tooling, Geographe remains dedicated to creating safer, more efficient maintenance.

Contact information

Geographe

480 Abernethy Road,

Kewdale WA 6105

Tel.: + 61 8 9449 1111

Email: sales@geographe.com.au

Web: www.geographe.com.au