Company Insight

Sponsored by HUESKER Australia

Unlocking Profit in Waste: The Economic Impact of Dewatering Tubes

Standfirst...

Main image credit:

Mine Waste Storage – Tailings Storage Facilities

Improvements in metallurgical technologies, the movement towards high volume processing and the development of lower cost extractive technologies has in some cases converted previously sub economic mineral concentrations into attractive ore bodies. Tailings storage facilities (TSF) are currently considered to be among the largest manmade structures, with the industry’s processing capabilities enabling the processing of large, lower concentration ore bodies, tailings volumes will in all likelihood increase to beyond what is currently the case. This will subsequently lead to larger impoundment storage volume requirements.

TSF’s are a cost to the mining process which do not generate a revenue stream for the mine owner. Due to this, innovation in TSF construction which contributes to the economic and environmental sustainability of mining operations is welcomed by the industry. However, recent failures in North and South America, Africa and Asia emphasize the need for any innovation in the field to be safe and to reduce the risk of failure.

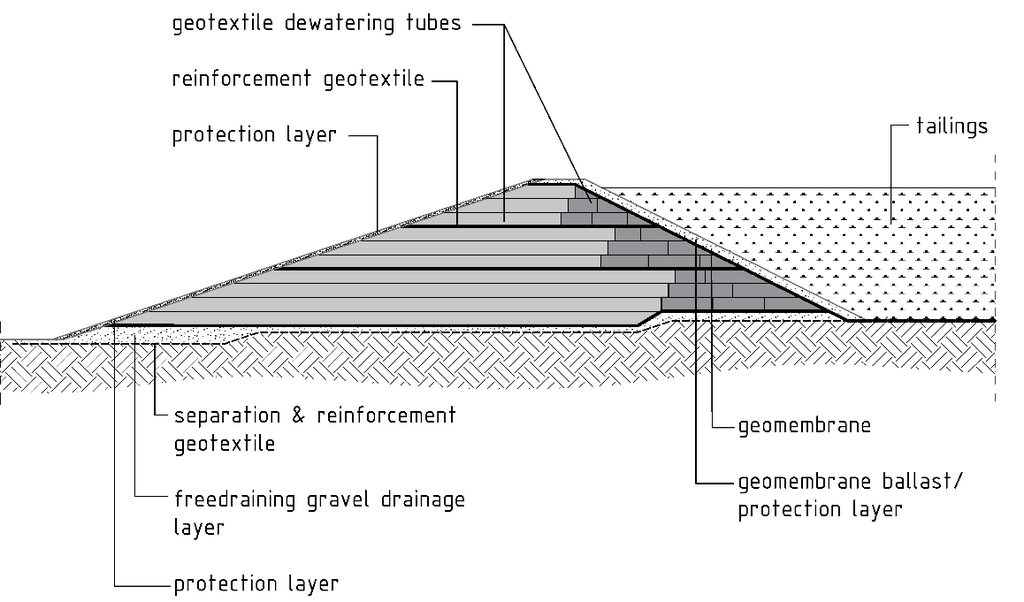

For several decades geosynthetics have been used successfully for mine related applications including the capping of residue lagoons, geogrid reinforcing of retaining structures, including dam walls, reinforcement of access roads, and lining of TSF’s and other impoundment facilities. In fact, almost all types of geosynthetics for the purposes of separation, filtration, drainage, reinforcement, protection, sealing and erosion protection can be applied within the wide application field of tailings dams.

Construction of critical structures using Dewatering tube technology, particularly embankments.

Geosynthetic dewatering tubes were originally developed for the purpose of dewatering of sewage and various residue sediments. The standard dimensions vary from tubes with 30m³ storage volume up to 65m long tubes with a volume of approximately 1,600m³ per tube. In combination with carefully selected flocculation agents almost every type of residue can be dewatered within the geotextile tubes, including both organic and inorganic substances. Once filled, the dewatering tubes are elliptically shaped, stable long geotextile containment elements designed with a dewatering and storage function.

Dewatering tubes are furnished with inlets, distributed along the longitudinal axis of the tube. The tube filling is undertaken through these inlets with the processed tailings slurry. Tubes can be installed in a single layer or stacked with multiple layers (Figure 1) to form a pyramidal type geometry.

Figure 1. Stacked dewatered geotextile tubes (5 tube layers high)

To maintain efficient staged construction of tailings dam embankments and to allow for optimum utilization of tailings storage facilities, the dewatering tubes must be placed and filled in such a manner to mimic regular downstream or upstream construction methodologies. Starter dam construction using dewatering tubes requires the tubes to be placed in the direction of the tailings dam embankment. By doing so this will enable the relatively fast installation of the subsequent geomembrane barrier and geomembrane protection layers. As future tailings dam raises become required, the dewatering tubes must be installed in the same directional manner (Figure 2).

When considering the equal loading of the base of the tailings dam embankment footprint it can be considered to place the geotextile dewatering tubes which do not form part of the starter walls perpendicular to the embankment direction, this will also provide greater embankment stability.

Figure 2. Concept layout of a downstream starter dam using geotextile tubes and geotextile reinforcement (if required to ensure stability)

Through dewatering and encapsulating tailings in geotextile dewatering tubes, the dry solid content is significantly increased which leads to increased undrained shear strength. Furthermore, the risk of seismic and static liquefaction is reduced, as the possibility of transient saturation is reduced due to the decrease in the void ratio of the contained tailings material.

HUESKER Australia carries the full suite of geosynthetics and has the engineering capability to assist any mine owner or their design team in the scoping, evaluation, design and implementation of construction of TSF embankments, sealing of bottom liners and capping and remediation of these facilities.

Contact information

HUESKER Australia

Ms Zehra Kaya - Director Civil

Tel.: +61 730 888 000

Mobile: +61 488 009 506

Email: zehra@huesker.co

Web: huesker.com.au