Company Insight

Sponsored by FuseTech International

Tackling abrasion

The benefits of FuseTech's crack-free plates in high-wear material processing.

Crack-free CCO plate.

FuseTech supplies crack-free Chromium Carbide Overlay (CCO) plates designed for material processing applications, delivering exceptional wear and impact protection. Utilising advanced fusion welding technology, these plates incorporate a highly abrasion-resistant chromium carbide layer on a mild steel base, ensuring maximum resistance to abrasion while reducing material build-up.

Based in Melbourne, FuseTech distributes the plates from its parent company and plate manufacturer, Futong.

In industries where heavy machinery faces constant exposure to abrasive materials, FuseTech's CCO plates offer a best-in-class solution. From mining to cement plants, these plates provide superior durability, reduce friction, and extend the lifespan of critical equipment.

We caught up with the team ahead of IMARC 2024, where they will have their CCO plates on display.

What are the key benefits of FuseTech’s smooth surface CCO plates compared to traditional options?

FuseTech’s crack-free CCO plates bring several key advantages over traditional options like quenched and tempered (Q&T) plates or conventional chromium carbide overlay (CCO) plates. First, our non-directional surface makes installation easier because you don’t have to worry about aligning the plate based on weld direction. Second, our plates perform exceptionally well in high-wear environments where Q&T plates tend to fall short, offering much-needed durability and protection. Plus, the low friction of our plates means materials slide off more easily, reducing carry-back and clogging—especially important in sticky or humid environments, like mining operations in hoppers and chutes.

Standard finish VS polished finish for areas requiring improved material flow.

What industries and plants can benefit most from FuseTech’s products, and what specific challenges do they address?

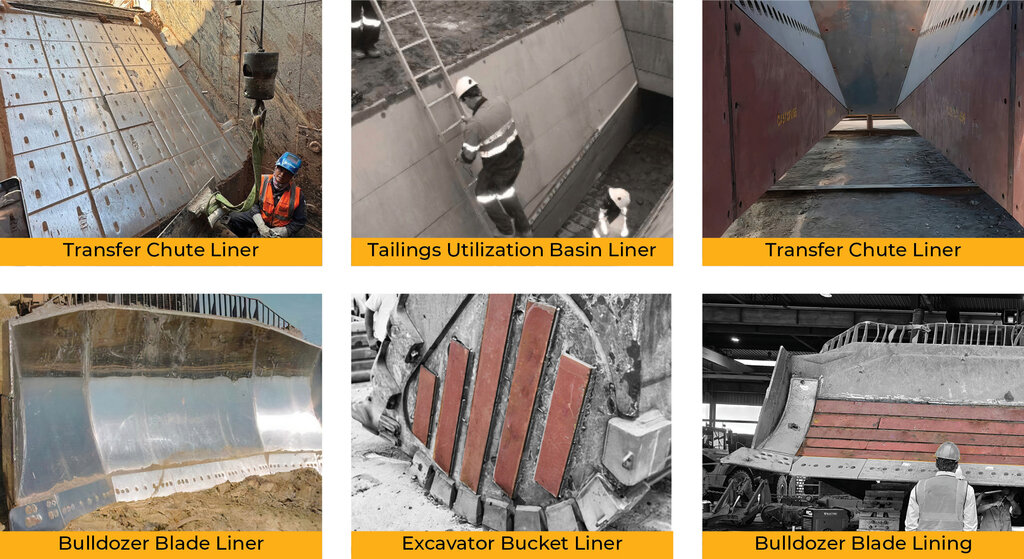

Our products are especially beneficial for industries dealing with bulk abrasive materials—like mining, aggregate, and cement plants. These industries face extreme wear and tear on equipment due to constant exposure to hard materials. FuseTech’s wear liners help protect crucial parts, such as transfer chutes and ground-engaging tools (GET), extending their service life and reducing downtime. In hard ore mining, for example, our liners shield key components from severe abrasion, making operations smoother and cutting maintenance costs. It’s all about providing durable, wear-resistant solutions that keep equipment reliable in high-impact settings.

Common applications and real-world client success cases.

How does FuseTech approach innovation and continuous improvement in its product offerings?

Seamless fusion line for stronger, longer-lasting plates.

We’re one of the few manufacturers that specialize in crack-free smooth surface CCO plates, and we’ve been refining these products for over 16 years. Our expertise is built on this long-standing focus on smooth hardfacing materials. We’re committed to continuous improvement, supported by rigorous in-house testing. Using advanced wear and impact testing machines, we continually assess and enhance the performance of our plates, ensuring they deliver top results even in the most demanding environments.

Can you share a success story or case study where FuseTech’s products significantly improved operations for a client?

One great example is our work with a major mineral processing company operating in a copper mine in Tibet. The high-altitude conditions create unique challenges, particularly during maintenance shutdowns. The company has to bring in technicians from other parts of China, which is both costly and tough for those unaccustomed to the altitude. By choosing our wear plates, they were able to extend the lifespan of their equipment, reduce the frequency of maintenance, and avoid costly, unplanned repairs. This has significantly helped them cut down on costs and keep their operations running smoothly despite the challenging environment.

What trends or challenges do you see in the mining industry, and how is FuseTech positioned to address them?

The mining industry is increasingly focused on sustainability, cost efficiency, and processing more abrasive materials in tough environments. Companies are under pressure to boost production while minimizing both downtime and environmental impact. FuseTech is in a strong position to help with these challenges. Our crack-free CCO plates are designed to extend the lifespan of critical equipment, which reduces repairs and downtime. Plus, with their low friction and non-directional wear surface, our plates enhance material flow and cut down on carry-back, improving overall efficiency in mining operations.

Team members in our parent company Futong’s China workshop.

Join FuseTech at IMARC 2024, booth R33, from October 30 to November 1, to discuss your wear challenges and explore how crack-free plates can help. The team would love to chat and offer a trial or sample from their Perth stock.

Contact information

FuseTech International Pty Ltd

Level 8, 220 Collins St,

Melbourne, VIC, 3000

Tel.: +61 4 8170 9997

Email: info@fusetech.au

Web: www.fusetech.au