The Pempek philosophy is the combination of its wide range of automation products to deliver complete, “turn-key” control system platforms for various types of mobile mining vehicles - such as Continuous Miners, Shuttle Cars, Feeder Breakers and Longwall Shearers.

By offering a complete, “turn-key” control system for each type of machine platform; Pempek provides the highest levels of safety and reliability while delivering the lowest cost of ownership of mobile machinery assets.

Mobile mining equipment asset management - It’s not easy

More than ever before, managing hazardous-area mobile mining assets is increasingly challenging.

The cost and complexity of essential safety technology must be managed alongside pressures to deliver consistent reliability and availability of assets to achieve critical production outcomes.

The volatility of global commodity markets further complicates the task of reducing the long-term cost-of-ownership of these assets.

The Pempek Value Proposition

Pempek’s unique technology solves this complex asset management problem via:

- Reliable, standard control packages for each machine type

- Management of all hydraulic and electrical automation

- Long-term component life-cycles

- Functional safety and explosion-protection Compliance

- Machine data collection and analysis

Reliable, standard control packages for each machine type

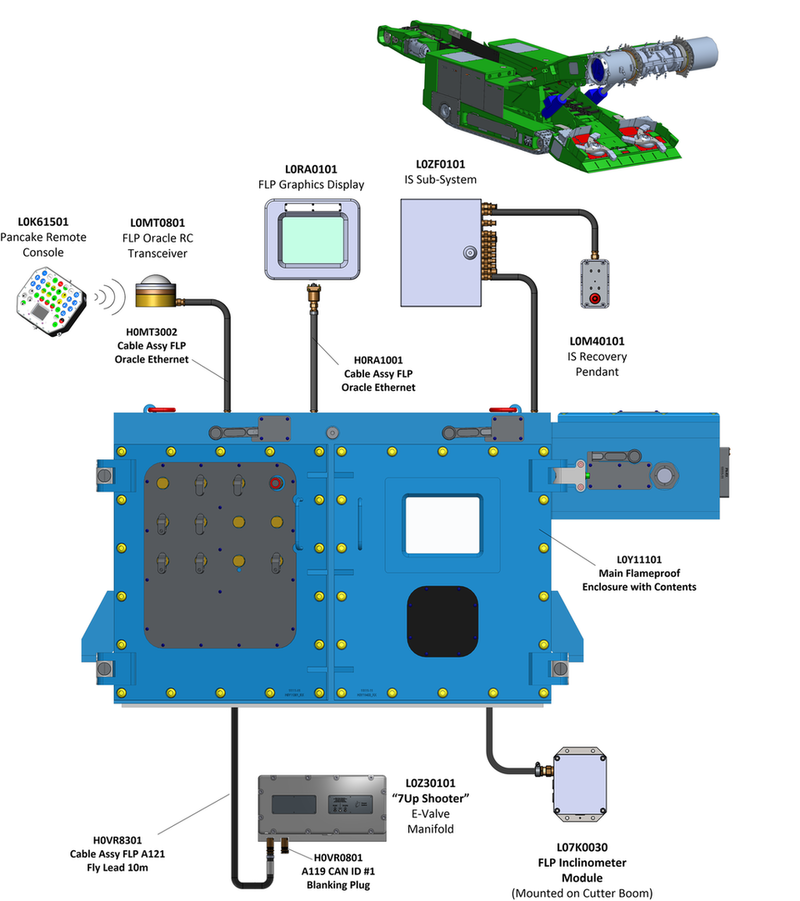

Pempek uses its wide range of control system components to tailor a standard control system package for each type of machine. Standard packages are available for:

- Continuous Miners

- Road Headers

- Longwall Shearers

- Shuttle Cars

- Feeder Breakers

- LHDs

The goal of this approach is to avoid the “gas factory effect” that often occurs when electrical and electronic components from various different manufacturers are put together to design a control system.

Pempek avoids the “gas factory” by providing a control system as a clean and simple homogeneous product supported by a single vendor.

The benefit to asset managers is that this approach avoids the infamous “finger pointing” that occurs when components and technologies from various different suppliers fail to operate cohesively.

Management of all hydraulic and electrical automation

Pempek designs and manufactures everything required to automate your mobile mining machine. This includes:

- Advanced machine automation software

- PLC control modules

- Radio remote control system

- Electric Motor Control and Protection

- Hydraulic System Control

Long-term component life-cycles

Technology obsolescence is the enemy of asset managers everywhere. The rapid pace of change in electronic technology means that automation products for non-mining applications quickly become obsolete and must frequently be replaced with new hardware.

This environment is at odds with the unique requirements of mobile mining plant where machines typically have an operating life expectancy of up to 15 years. The challenge for asset managers is to avoid the considerable cost of completely changing the control system during each rebuild cycle.

Pempek solves this problem by maintaining design and manufacturing control of all mission-critical control system components. Pempek’s commitment is to maintain the life-cycle of components over a minimum 15-year period. In many cases, this allows the same componentry to be re-deployed in the same machine over the full life-cycle of the machine’s operation.

Functional Safety and Explosion-protection Compliance

Pempek manages the complex task of compliance to international functional safety and explosion-protection standards through:

- Design to internationally-recognised functional safety standard (IEC 61508)

- International explosion-protection certification of all control system components

Machine data collection and analysis

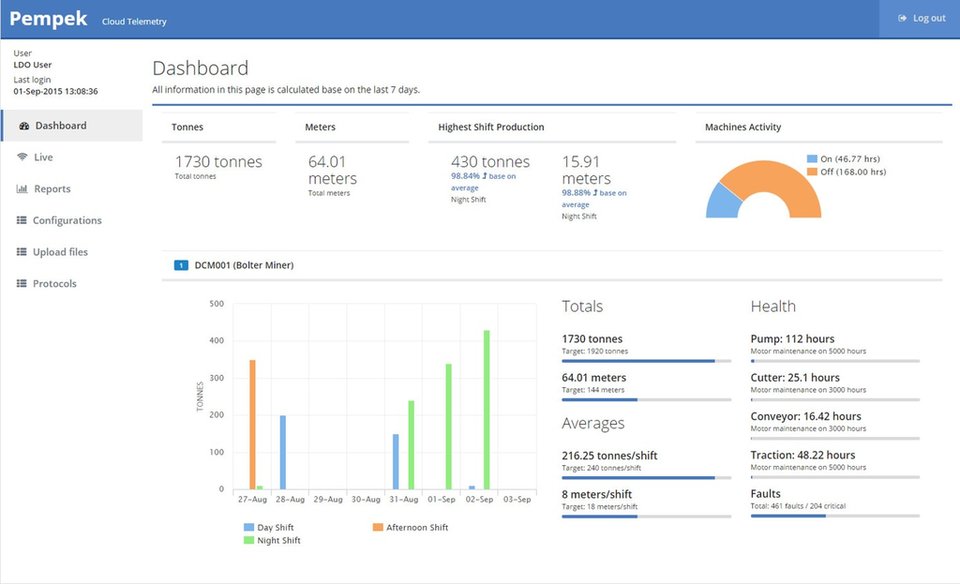

Integrated into each control system is Pempek’s “Cloud Telemetry” data collection platform.

The system can be connected to the Internet where machine data is collected, stored and analyzed. Machine owners can then access maintenance and production data and reporting via mobile devices from anywhere in the world.

About Pempek Systems

Since 1988, Pempek Systems has been designing and manufacturing electronic control system products for the global mining industry.

Pempek’s headquarters are based in Sydney, Australia and the company maintains a worldwide network of facilities and distributors in several countries.

Pempek’s product range covers a full suite of control and automation components for mobile machinery; including PLC modules, graphics displays, motor drives (AC and DC), radio remote control and electric-over-hydraulic control units.

For more information about Pempek products and soultions feel free to e-mail:

Contact information

Unit 3 - 13 Hoyle Ave

Castle Hill NSW 2154

Australia

Web: www.pempek.com.au

Email: davidc@pempek.com.au

Tel: +61 (0)2 8853 4800

Mobile: +61 (0)400 080 153

Fax: +61 (0)2 9894 0379