COMPANY INSIGHT

Sponsored by Hawk Measurement

Process Instrumentation and Fiber Optic Sensing Systems

Hawk Measurement Systems (HAWK), is the world leader of process instrumentation solutions and is the trusted name for many of the largest mining companies throughout the globe.

H

AWK specializes in reliable and continuous level measurement in storage silos on conveyor belts, clarifiers, thickeners, crushers and blocked chute detection with the ability to send real-time data to a computer, control room, or smartphone. The mining industry presents unique challenges due to dust, mud, impact, abrasion and build-up of material on sensors and plant, which HAWK has successfully solved for over 30 years.

Radar Sensors for Level, Distance and Volume

The Senator Free Space Radar Level Transmitters are non-contacting and use FMCW (Frequency Modulated Continuous Wave) technology. They have the ability to measure distance, level, and volume of liquids, solids, corrosives, powders, granulates, rocks, pastes, and hygienic liquids. There are six transmitters to choose from, providing a solution for practically any application.

Self-Cleaning Acoustic Wave Transmitter for Liquids, Slurries and Solids

The Sultan Transmitter features Acoustic Wave technology, which is the pinnacle of non-contacting level measurement. Designed with a built-in self-cleaning feature, this low maintenance robust sensor self-cleans any build up from dirt, dust, and debris.

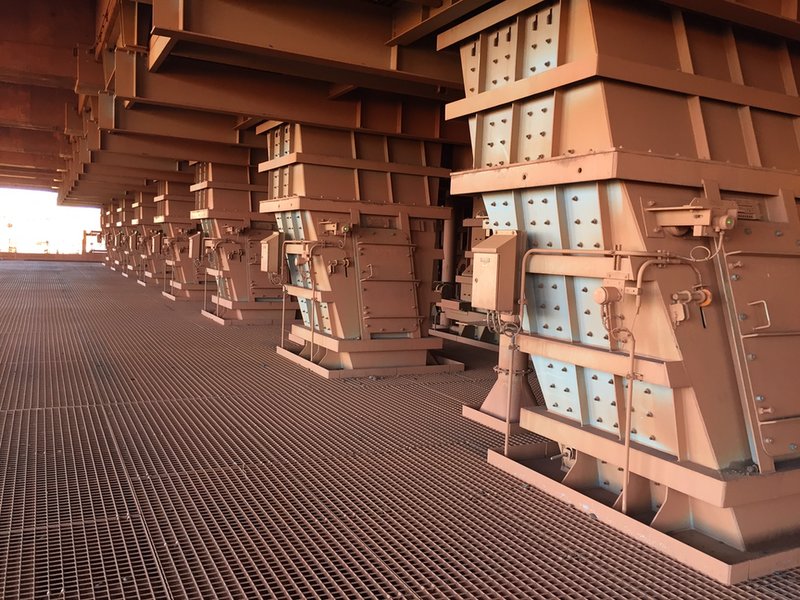

Blocked Chute Detection and Prevention

HAWK'sGladiator Blocked Chute Switches provide point level switching for the presence or absence of most solid materials. HAWK’s blocked chute switch is 50 times more sensitive than the competition, allowing it to predict blockage and build-up before it occurs. Eliminate downtime and increase productivity and profitability with HAWK’s durable line of blocked chute switches.

Fiber Optic Sensing for Conveyor Health and Tailings Dams

HAWK is the only process instrumentation company to also design and develop a Fiber Optic Sensing System.The Praetorian features revolutionary Fiber Optic Sensing technology that allows for real-time measurements of long assets such as conveyors,tailings dams, pipelines, power cables and perimeters by monitoring changes that occur in a fiber optic cable affixed to the asset.

About Hawk Measurement Systems

Hawk Measurement Systems (HAWK), a world leader in level, positioning, asset monitoring and flow measurement technology, provides cutting-edge equipment and complete solutions to the mining industry and the global industrial market. HAWK specializes in reliable and continuous level measurement in storage silos, on conveyor belts, thickeners, crushers and blocked chute detection with the ability to send real-time data to a computer, control room, or smartphone. HAWK has a long history of success in the harshest of environments and applications. HAWK has won several prestigious awards for their breakthrough technologies.

Some of these technologies include Acoustic Wave, Ultrasonic, Microwave, Radar, and Fiber Optic Sensing. HAWK designs and develops innovative measurement technology that is extremely reliable and accurate, simple to install, easy to operate and offers maximum efficiency. The mining industry presents unique challenges due to dust, mud, impact, abrasion and build-up of material on sensors and plant, which HAWK has successfully solved for over 30 years. HAWK is committed to providing best-in-class products, services and technologies that will have unsurpassed value for their customers.

HAWK currently has two manufacturing facilities, headquarters in Melbourne, Australia and the USA manufacturing facility in Medina, Ohio.