COMPANY INSIGHT

Sponsored by Interlate

Data Solutions for Minerals Processing Companies

Xore’s offer is to raise the productivity of a concentrator plant by enabling better process control. By providing fast and accurate analysis our products are valuable tools to process engineers and operators in some world class mining operations.

I

nterlate® offers proactive solutions to improve decisions, enhance operational productivity, and deliver increased returns to all their stakeholders while driving transformation toward a sustainable future. We specialise in digital enablement and upskilling, process optimisation, decarbonisation and economic uplift via focused customer engagement.

Specialist services

Interlate® minimises time-to-value by focusing on quick wins and building foundations for advanced tech.

We assist clients by:

- Overcoming implementation issues and securing value

- Providing data location flexibility

- Taking a longer-term focus towards more challenging operational problems or supporting your team’s digital journey

- Working in real-time

- Upskilling customers by providing relevant software and knowledge

Interlate® can blend the right combination of decision-making software, people enablement and value-driven services to meet your needs. Ranging from data analytics to training, our lightweight and real-time operational services aim to enhance remote or on-site operations.

Our services include:

- Digital Readiness: assessments to help accelerate your journey. Clients can understand the opportunities in their digital assets from a standardised analysis of data-driven decision-making.

- Data architecture: fuse data sources from disparate sources and enterprise systems to improve decision-making at the interfaces along a value chain. It demonstrates the benefit of utilising intelligence from adjacent systems (e.g., Mine Dispatch + Process Historian).

- Data analytics: generates immediately deployable operating tactics from data already available in your operations. Targeted problem solving (eg: tactics to meet decarbonisation targets while maintaining or improving productivity) that is scaled according to specific timeframes.

- Benchmarking: understand the opportunities in your process from a standardised analysis of performance and stability to provide strategic insight into a longer-term improvement roadmap and your digital journey. This can include Carbon Benchmarking.

- Capability Building: short courses focused on data-driven decision-making for mining professionals, leveraging Interlate’s service expertise and on-site experience of our team. Accelerate digital capabilities and improved decision-making skillsets within your teams.

We also offer a customisable four to six-week package that contains some or all the above modules, resulting in a tailored digital accelerator aimed at gaining immediate value-momentum.

Our real-time services include:

- High-level analytical services (HLA) for daily tactical analytics, on-demand. This immediately integrates fast turnaround operating tactics into your technical or operational teams, focused on current operational issues or overflow work.

- Our patented Sentinel® real-time analytical and decision support services, which is a long-term productivity uplift service focused on both decision support and larger / complex process improvement projects.

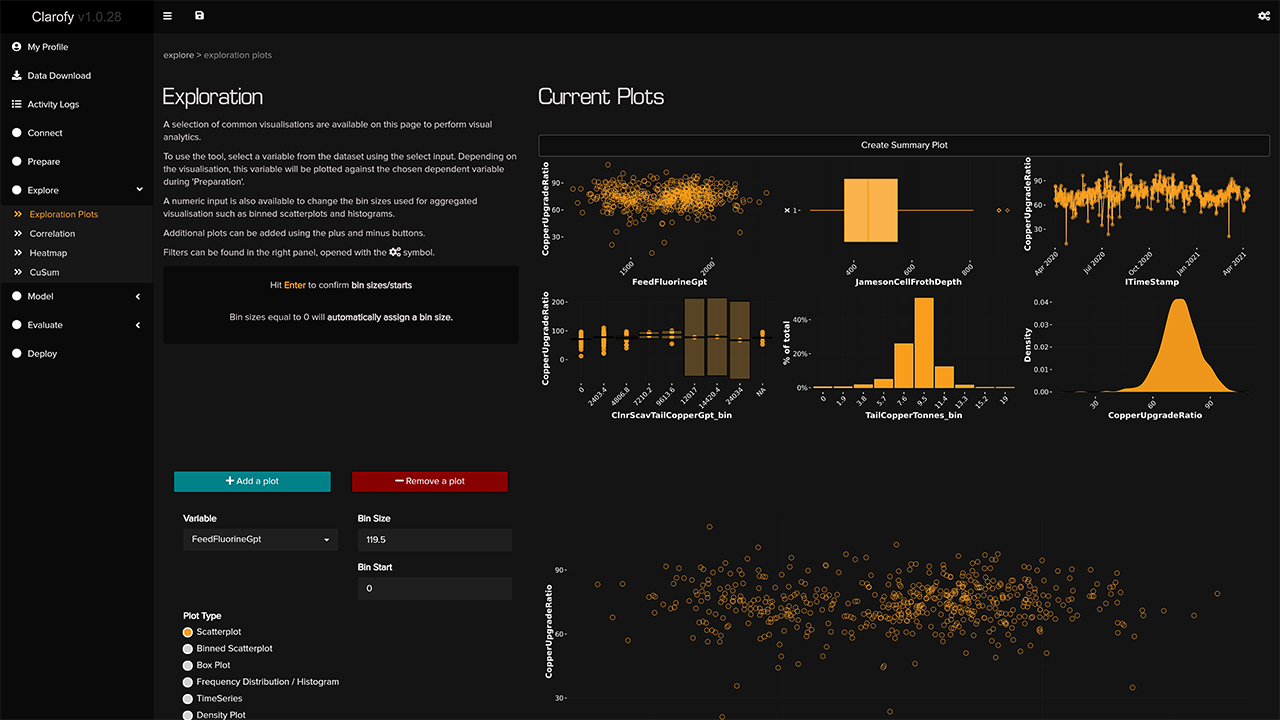

Data science application for mining professionals: Clarofy®

Leveraging the domain knowledge and on-site experience of our highly skilled operational and process engineering professionals, combined with the skills of our leading data scientists, Interlate has developed a practical, fast and targeted software application.

Clarofy is a complete end-to-end industrial data science application enabling data description, exploration, modelling for prediction and prescription, and comparative statistics. The plant asset, commodity and value-chain agnostic solution enables users to explore relationships between their plant operating variables and update their operating strategies. A range of deployment options are available; from static to real-time to match your solution and plant needs. Clarofy was primarily developed around continuous processes but has an ever-expanding capability.

Clarofy’s standardised analytical workflow gives you a streamlined, integrated experience, and coming soon; the advanced capability to build your own data science workflows! Spend less time analysing data, and more time implementing value in the plant.

In addition, productivity and sustainability deliverables are quantified for easy communication, so you can demonstrate the value of your data and analytical skills with serious value propositions.

Clarofy can also be an engine for upskilling the site workforce in data science and data management. Processing plants are data-rich but can often be information-poor without the application of data-driven tactics and strategies. Data-driven decision making requires a robust foundation of statistics to cut through the ‘noise’ of plant data, isolating issues and allowing operations to maximise recoveries/yield. A Clarofy subscription can be packaged with a Capability Building program for your team to get the most out of the app and expand their statistical and digital capabilities.

Custom apps

Interlate® can create custom apps to help clients automate the decision-making process, or to solve a specific problem.

Case Study: Our Net Smelter Return (NSR) Optimisation app, originally created as a custom app for a client, combines process modelling with optimisation to determine high-level production targets. The app also outputs target product grades on parallel minerals processing lines to optimise overall cash flow. The user can dynamically change market and feed assumptions for real-time decision-making or longer-term production planning.

The NSR app can be customised to your process or modified for a different application such as decarbonisation. Changing assumptions around production can create emissions scenarios for forecasts or tracking.

Why LaseTVM-Line

EXPERIENCE

30 years of experience in laser measurement technology for volumetric measurements in mining, steel, bulk material logistics, ports etc.

RELIABILITY

Reproducible, non-manipulable measurements, exclusion of the human error factor.

ACCURACY

Exact determination of volume, excludes inaccuracies due to material moisture.