The mining industry continues to be a hotbed of innovation, with activity driven by the need for improved productivity, safety and more sustainable mining and mineral processing practices. Extraction and primary processing of metals and other minerals are responsible for 26% of global carbon emissions.

By nature, mining depletes natural resources and has a significant impact on surrounding ecosystems. However, metals and minerals will play an important role in the global transition to a greener future. Therefore, adequate investment should be made in technologies related to environmentally sound extraction, processing and rehabilitation to keep up with increasing ecological vulnerabilities.

Companies must reduce their greenhouse gas (GHG) emissions, reduce their environmental impact and mitigate risks. In the last three years alone, there have been over 48,000 patents filed and granted in the mining industry, according to GlobalData’s report on Environment Sustainability in Mining: Solvent Extraction Processes.

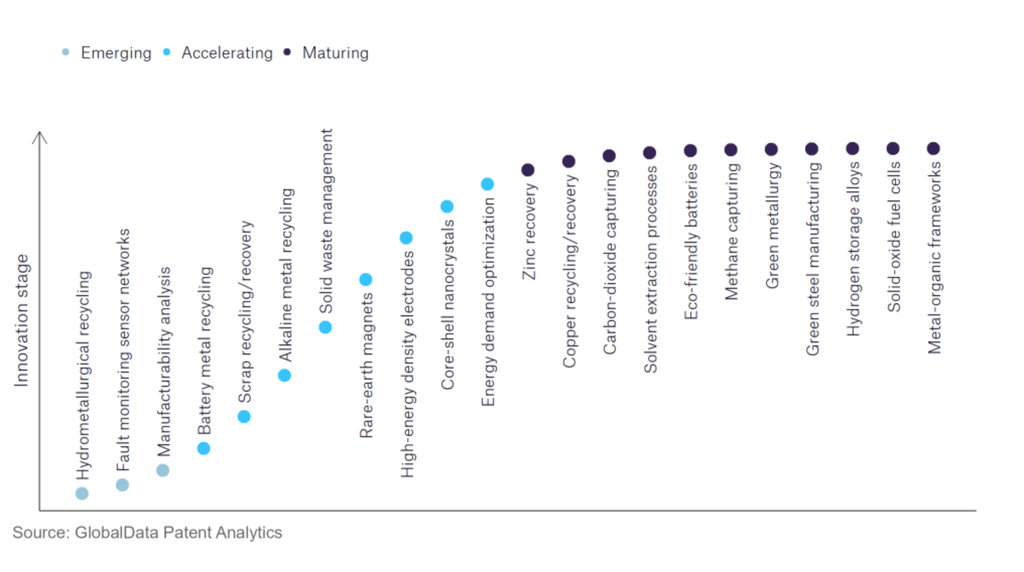

However, not all innovations are equal and nor do they follow a constant upward trend. Instead, their evolution takes the form of an S-shaped curve that reflects their typical lifecycle from early emergence to accelerating adoption, before finally stabilising and reaching maturity.

Identifying where a particular innovation is on this journey, especially those that are in the emerging and accelerating stages, is essential for understanding their current level of adoption and the likely future trajectory and impact they will have.

150+ innovations will shape the mining industry

According to GlobalData’s Technology Foresights, which plots the S-curve for the mining industry using innovation intensity models built on over 350,000 patents, there are 150+ innovation areas that will shape the future of the industry.

Within the emerging innovation stage, high-energy density electrodes, manufacturability analysis and solid waste management are disruptive technologies that are in the early stages of application and should be tracked closely. Green steel manufacturing, scrap recycling/recovery and core-shell nanocrystals are some of the accelerating innovation areas, where adoption has been steadily increasing. Among maturing innovation areas are green metallurgy and solvent extraction processes, which are now well established in the industry.

S-curve for environmental sustainability in the mining industry

A key innovation area in environmental sustainability

Solvent extraction is the process in which a compound transfers from one solvent to another owing to the difference in solubility or distribution coefficient between these two immiscible, or slightly soluble, solvents. Solvent extraction is an important technology for separating, purifying and recovering metals from solutions, particularly uranium, copper, nickel, cobalt and rare earths. The process transfers selected metals from one aqueous solution to another using an organic solution containing a special reagent allowing metals to be separated, purified and recovered.

GlobalData’s analysis also uncovers the companies at the forefront of each innovation area and assesses the potential reach and impact of their patenting activity across different applications and geographies. According to GlobalData, there are 50 companies, spanning technology vendors, established mining companies and up-and-coming start-ups engaged in the development and application of solvent extraction processes.

A disruptive innovation in the mining industry

‘Application diversity’ measures the number of different applications identified for each relevant patent and broadly splits companies into either ‘niche’ or ‘diversified’ innovators.

‘Geographic reach’ refers to the number of different countries each relevant patent is registered in and reflects the breadth of geographic application intended, ranging from ‘global’ to ‘local’.

Leading companies include Metso Outotec, which extracts over 30% of the world’s copper using the Vertical Smooth Flow (VSF) solvent extraction process. With decades of solvent extraction experience, the company's VSF plants offer lower lifetime costs, significantly shorter lead times and sustainable life-cycle technology.

Metso Outotec signed an agreement with Li-Cycle North America Hub in December 2021 to supply manganese, cobalt and nickel solvent extraction technology for a battery recycling plant in the US. Metso Outotec will supply three modular VSF®X solvent extraction plants, as well as associated Dual Media Filters and basic engineering.

To further understand the key themes and technologies disrupting the mining industry, access GlobalData’s latest thematic research report on Mining.

GlobalData, the leading provider of industry intelligence, provided the underlying data, research, and analysis used to produce this article.

GlobalData’s Patent Analytics tracks patent filings and grants from official offices around the world. Textual analysis and official patent classifications are used to group patents into key thematic areas and link them to specific companies across the world’s largest industries.