company insight

Sponsored by: IDCON INC

Improving Efficiency and Productivity through Reliability

Mines face tough challenges that can impact reliability and maintenance practices - from health and safety regulations to sliding productivity and costs. These challenges will often require some sort of change.

Regardless of how people are going about a change, the human element of change is universal. People do not like change, especially if an outsider tells them HOW to change. Having worked in many different organizations and in many different countries, I’ve reflected a lot on what’s needed to improve and change work methods. I don’t have all the answers, but I believe I have found some valuable points.

More than half of the country’s coal mines are managed by pro-Russian separatist militia.Credit: DmyTo/Shutterstock.

More than half of the country’s coal mines are managed by pro-Russian separatist militia.

Credit: DmyTo/Shutterstock.

Good maintenance is highly dependent on human behavior

Machines largely run the operation at the mine. The people who run the equipment have to follow the pace of both the equipment and production. Poor operating practices are very noticeable. Maintenance efficiency is developed through better work processes. For example:

An inspector can carry out detailed inspections, or just walk around and look busy.

A maintenance job can take 10 hours or four.

A planner can plan a task very well, or just order spare parts.

As a maintenance manager, it’s crucial to understand that 90 percent of maintenance effectiveness depends on human behavior.

Describe and relay a clear picture of change

Maintenance improvements need to be clearly defined. It’s not enough to just explain how to get there, you must be able to provide a clear picture of what things are supposed to look like in the future. For example, if you want to improve planning and scheduling, there should be a description of what the work process should look when you’ve improved.

At IDCON we have defined Work processes and use this as the basis for assessing a mine’s reliability and maintenance management performance. When we assess we look at how well each process is:

- Documented

- Executed

- Followed up

The future picture is summarized in these bullets as headers. Let’s take a look at improving Planning and Scheduling at your mine.

Under “documented” you would describe what documents should be in place when you’re are finished with the improvements. At the bare minimum you want a clear workflow, a definition of planning, defined priorities and so on.

Figure 1: As part of the "documented" in a planning and scheduling improvement. A priority chart of work notifications would be included. A guideline such as this should be highly visible throughout the plant.

Communicating

If you want to get people involved, think about HOW you communicate. Compare these questions:

” Our documentation for work order flow is really bad, why are we performing so poorly?”

” Can our documentation for work order flow improve?”

I believe the project group would work in the same direction in both cases, but with much more enthusiasm and drive if you chose the second more inclusive question.

Since maintenance is based on human behavior, it is important that we as maintenance leaders think about how we relay the message. Words are important! Speaking of communication, it’s not enough just to post a priority guideline like Figure 1 in a notebook, it must be highly-visible and you must give feedback when the wrong priority is chosen by the person requesting the maintenance work.

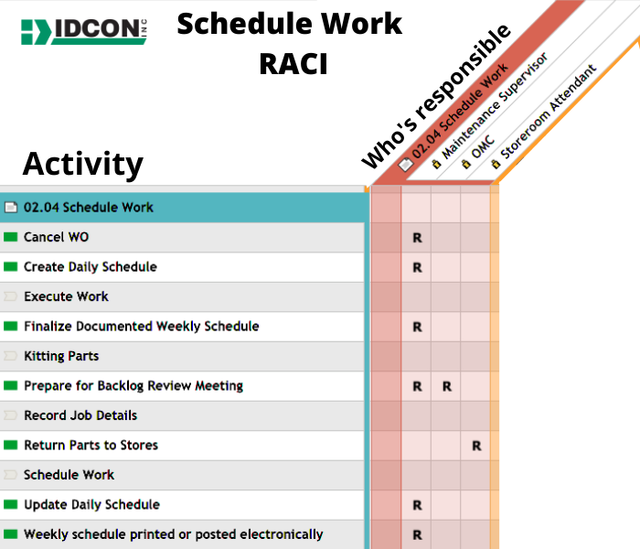

Figure 2: Example of a partial Work Process Flow for Scheduling Maintenance Work. The Roles and responsibilities are identified for tasks, meetings and cut-off times. The Black boxes are the inputs and outputs. 2c8 is the software used in this model.

Figure 3: Another view of a RACI chart showing the tasks, decision questions, and descriptions. This is also a Scheduling RACI. It should be noted that the RACI may contain roles not present at your site.

The examples above are just a few possibilities of what can be utilized in an improvement project. If you have good examples of how your mine made (or is making) changes to improve the reliability and maintenance practices we’d love to hear about them. You can email us using the contact information below.

If you want to assess how well your mine’s performance of the essential elements of reliability give us a call or email and we’ll discuss your options.