Company Insight

Sponsored by Pirtek Fluid Systems

Pirtek: The leader in fluid transfer solutions for mining and industry

Standfirst...

Main image credit:

Since its inception in 1980, Pirtek has been at the forefront of the fluid transfer solutions industry. What began as a local endeavour has blossomed into a global leader, providing an extensive range of products and services to a diverse customer base. With over 23 countries served, 330+ centres, and 1500+ Mobile Service Units, Pirtek’s leadership has earned it a reputation as the world's premier supplier of fluid transfer solutions. This success is driven by a unique business model that combines the agility of local businesses with the strength and resources of a global network.

Pirtek’s structure as a network of locally-operated franchises ensures that every customer receives personalised service while benefiting from the collective knowledge and resources of a global entity. This allows Pirtek to deliver unmatched expertise and support, making it a truly unique player in the industry.

Hose solutions for the mining industry

At the heart of Pirtek’s product lineup is its range of state-of-the-art hoses, designed to meet the rigorous demands of various industries, particularly underground mining. Pirtek’s hose products are engineered for safety, reliability, and superior performance, ensuring minimal downtime and maximum operational efficiency for its customers.

Here’s a closer look at some of the key products in Pirtek’s underground mining range:

20 Bar Rubber Delivery Hose:

Applications: Air, water, and stone dust transfer.

Features: Made with a heavy-duty FRAS rubber compound for the inner tube and outer cover, reinforced with high-strength textile braid.

Sizes: Available from 0.5 inches to 4 inches.

Benefits: Designed for the toughest underground environments, ensuring durability and reliability.

10 and 20 Bar Rubber Suction and Delivery Hose:

Applications: Air, water, and methane gas drainage.

Features: Heavy-duty FRAS rubber compound with wire reinforcement.

Sizes: Available from 2 inches to 6 inches.

Benefits: Offers robust performance and safety in demanding conditions.

20 Bar PVC FRAS Pressure Hose:

Applications: Compressed air and water transfer.

Features: Lightweight with a high-abrasion resistant safety yellow outer cover and high-strength textile braid reinforcement.

Sizes: Available from 3/8 inches to 2 inches.

Benefits: Ideal for extreme conditions, combining light weight with high durability.

Low-Pressure FRAS Rubber Push-On Style Hose:

Applications: Air, water, and hydraulic oil.

Features: 21 bar of isobaric pressure, suitable for crimp or push-on fittings.

Sizes: Available from 1/4 inches to 3/4 inches.

Benefits: Versatile and easy to install, perfect for a range of applications.

Caption. Credit:

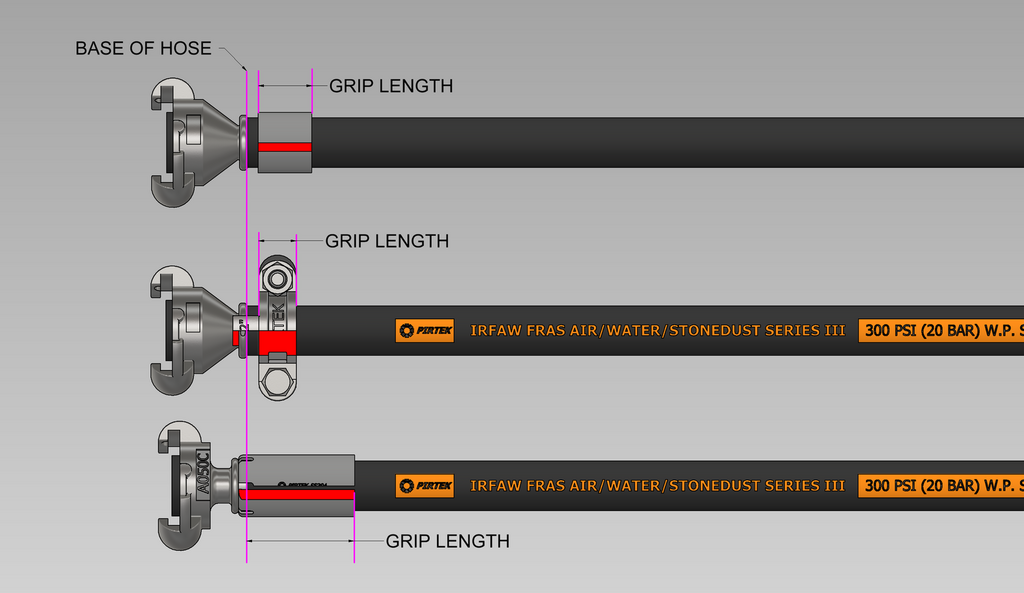

Innovative retention systems

Pirtek offers advanced retention systems designed to secure hose fittings, preventing leaks, accidents, and fitting blow-offs. These systems ensure the safety and reliability of hose assemblies, especially in demanding environments like underground mining. Basic coupling assembly rings provide minimal retention with a small surface area of compression. This inadequate retention increases the risk of hose blow-offs and leaks, posing significant safety hazards and making it unsuitable for critical applications.

Traditional Double Bolt Safety Claw Clamp

Design: Provides retention at two points, offering a more secure connection than the basic coupling ring.

Benefits:

- Enhanced Safety: Reduces the risk of hose blow-offs and leaks by providing a higher level of retention.

- Greater Reliability: Suitable for more demanding applications, ensuring a more reliable connection.

Pirtek’s Crimp Solution: The Preferred Method

Design: Offers 360° interlocking retention with a larger surface area compression of the hose, ensuring an even distribution of pressure.

Benefits:

- Increased Safety: Ensures the hose remains securely attached, significantly reducing the risk of blow-offs and leaks.

- Positive Retention: Provides a stronger and more reliable connection.

- Fewer Leaks and Accidents: Minimizes risk, making it the safest option available.

- No Protruding Parts: Reduces injury risk, enhancing the safety of hose assemblies.

- Operational Efficiency: Reduces downtime, ensuring continuous and efficient operations.

Caption. Credit:

Commitment to quality and safety

Pirtek’s dedication to quality is underscored by its investment in all stages of the supply chain, including an on-site NATA certified testing laboratory. This ensures that every product meets the highest standards of safety and performance. Pirtek’s hoses are precision-engineered, laser-measured, and batch-coded to maintain consistency and reliability. The company’s rigorous testing procedures, including fire resistance and antistatic tests, ensure that its products are fit for the most hazardous conditions.

Comprehensive service and support

Pirtek’s commitment to its customers extends beyond product supply, and includes a service package with 24/7 support, proactive maintenance, and expert advice. With a robust network and a dedicated team, Pirtek ensures that its customers’ operations run smoothly, minimising downtime and maximising productivity.

For over four decades, Pirtek has been synonymous with quality, reliability, and innovation in fluid transfer solutions. Whether you are a large-scale mining operation or a small local business, Pirtek’s expertise and products will keep you operating at peak efficiency, ensuring you are always prepared for the challenges of tomorrow.

Contact information

Pirtek Fluid Systems Pty Ltd

3-7 Garling Road

KINGS PARK, NSW 2147

Tel.: +61 2 8822 9041

Mob: +61 427 915 459

Email: WHolland@pirtek.com.au

Web: www.pirtek.com.au