Company Insight

Sponsored by Emesent

Taking on the abyss

Emesent’s Hovermap ventures into Carrapateena’s mega cave.

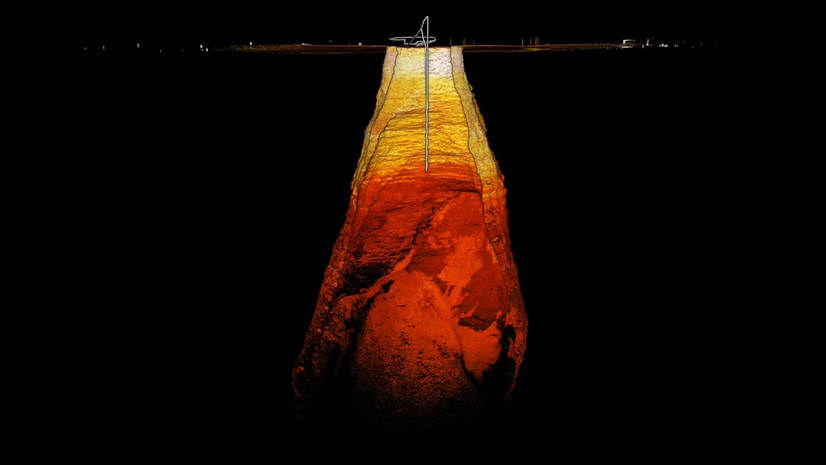

Hovermap point cloud of the Carrapateena “mega cave” diving below the surface.

South Australia’s Carrapateena copper mine is one of those places where technology has to take a leap—literally—into the unknown. Owned by OZ Minerals until its recent acquisition by BHP, Carrapateena isn’t just a mineral treasure trove; it’s a high-stakes engineering puzzle. The mine’s “mega cave,” created through a sublevel caving method, is a deep, shifting expanse that’s as challenging to navigate as it is valuable to mine. And when it comes to mining at these depths, safety and precision are non-negotiable.

For Emesent, a leader in autonomous systems and LiDAR mapping, Carrapateena posed a perfect challenge. The cave was so vast and unpredictable that traditional surveying equipment was simply out of its depth. But Emesent’s Hovermap—a game-changing drone-integrated solution—was designed for exactly these kinds of environments. By combining autonomous navigation and LiDAR scanning, Hovermap gave Carrapateena something no other system could: safe, hands-off access to the depths of the mega cave, capturing crucial data that can keep operations running smoothly and, most importantly, safely.

Mega cave point cloud and drone trajectory from a previous autonomous Hovermap scan, overlaid on an aerial image of the area, highlighting the cave’s size and the exclusion zone.

Why Carrapateena needed a solution like Hovermap

Carrapateena isn’t just another copper mine—it’s one of Australia’s largest, producing about 4.25 million tonnes of copper each year. But that production comes with unique challenges. The sublevel caving method used here allows the ground above the ore to collapse gradually, forming a massive cave filled with rock debris. It’s efficient for getting to valuable ore, but it also risks creating dangerous air gaps and pressure shifts that could spell disaster if they’re not managed carefully. Regular scans of this massive space are crucial to:

- Ensuring the safety of mine operations, both above and below ground.

- Tracking cave growth and stability to prevent any unexpected shifts.

- Optimizing mining plans by updating geotechnical models with accurate, current data.

Traditional tools like terrestrial LiDAR just couldn’t reach far enough, and drones or helicopters weren’t practical because they require a clear line of sight. So, when Carrapateena’s team turned to Emesent, Hovermap stepped up with its combination of autonomous navigation and high-res LiDAR mapping, designed to go where no other technology could go.

“The sheer scale of the sinkhole makes it hard to fathom the complexities of such an inaccessible environment. But to put it into perspective, Rome's Colosseum could fit inside. That says a lot about the distances required to travel and the risks involved in mapping the location, and why Emesent's autonomous mapping technology—which drives Hovermap on a drone—offers such key value in ensuring the safety and productivity of sites like these.” - Dr Stefan Hrabar, Co-founder and Chief Strategy Officer at Emesent.

How Hovermap works in the field

Deploying Hovermap at Carrapateena is like watching a mini sci-fi adventure unfold. Attached to a DJI M300 drone, the Hovermap unit—known for its precise autonomous flying—was launched from a safe distance of 300 meters from the cave entrance. It initially relied on Pilot Assist mode to navigate into position, then, once at the cave’s edge, Hovermap’s autonomous mode took over.

With no GPS or operator control deep inside the cave, Hovermap ventured forward, descending into the shadows about 70 meters and scanning the void. The entire mission took 15 minutes, during which Hovermap captured a detailed 3D model of the cave. After the mission, it took just 25 minutes for the system to render a high-res 3D visualization, delivering vital insights right to the team.

Caption:

Mapping the cave: What Hovermap found

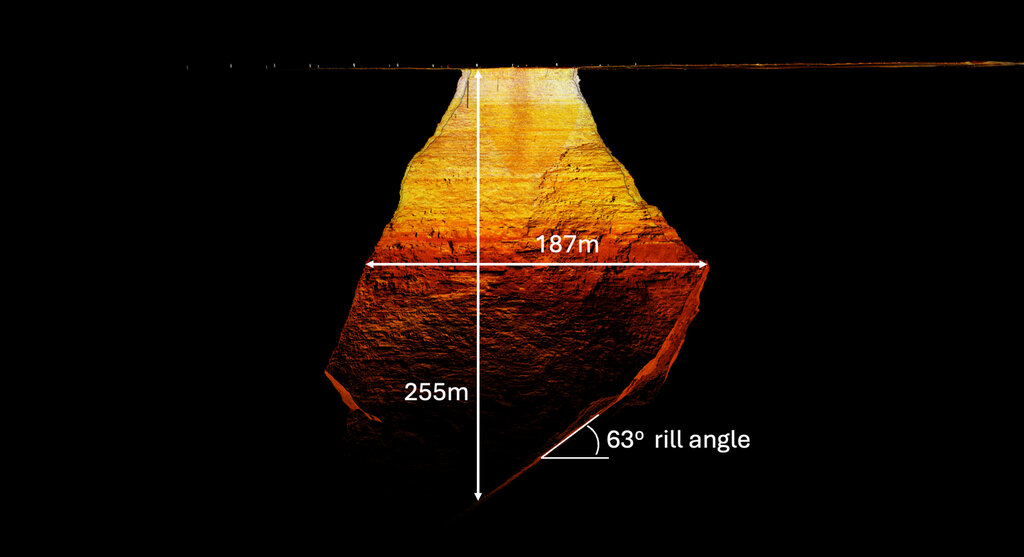

Hovermap’s data revealed that Carrapateena’s mega cave was larger than anyone had anticipated. What started as a small surface hole had grown into a 63-meter-wide opening, descending 40 meters before expanding 187 meters wide and reaching depths of 255 meters. The scan also uncovered potential hazards like dangling wires from old infrastructure near the entrance, which could be risky for future drone flights.

Cross-section of the mega cave point cloud, showcasing its depth, width, and the slope of the muck pile.

Crucially, Hovermap’s insights on the muck pile—essentially the collapsed rock at the cave’s floor—were instrumental in helping Carrapateena’s geotechnical team track cave stability and avoid dangerous air gaps. With monthly scans planned going forward, the team now has a clear, ongoing picture of how the cave is evolving.

A new era of safety and productivity for Carrapateena

Hovermap is much more than a fancy piece of tech; it’s an operational lifeline for challenging environments like Carrapateena. Its autonomous capabilities mean high-fidelity data can be gathered from the cave without putting anyone in harm’s way, keeping the mine running and the people safe. For every hour saved in operations, the mine avoids significant production losses—Hovermap is already paying dividends.

“The ability to regularly survey the Carrapateena mega cave marks an important de-risking event for ongoing operations and enables mine planning to be safely optimized for production. It’s testament to the advanced autonomous capabilities of Hovermap that we were able to capture critical data for decision-making that otherwise would simply not have been possible.” - Richard Cheung, Digital Robotics & Automation Architect at BHP.

What sets Hovermap apart

Hovermap’s success at Carrapateena shows how hardware and software can work together seamlessly. Paired with the DJI M300, the Hovermap ST-X LiDAR payload delivers real-time data via Emesent’s Commander app and Aura software, which handles post-mission processing. With a Samsung tablet and GoPro camera on board, Hovermap generated a level of detail that exceeded expectations. Meanwhile, Emesent’s Cortex software enabled autonomous flight and obstacle avoidance amongst Carrapateena’s challenging terrain.

The bigger picture: How autonomous systems are transforming mining

In an industry constantly seeking safer, more efficient ways of operating, Hovermap has proven to be more than just a technical achievement; it’s a glimpse into the future of mining. As operations push further underground, this innovation will become essential for managing safety and productivity.

Caption

Contact information

Head Office

40-52 McDougall Street,

Kings Row Office Park

Level G, Building 4

Milton, Queensland, 4064, Australia

PO Box: 1401 Milton QLD 4064

Tel.: +61 7 3548 9494

Europe Office

483 Green Lanes

London N13 4BS

United Kingdom

Tel.: +44 7551 534 359

North American Office

9200 E. Mineral Ave. #100

Centennial, CO 80112

Web: www.emesent.com