Company Insight

Sponsored by MATO Australia

Conveying quality: How MATO leads the way in belt maintenance equipment

Standfirst...

Main image credit:

Established in 1906, MATO has been a stalwart in the mining industry, originally focusing on coal mining operations. Over the years, the company has diversified its offerings to become a leading provider of belt maintenance products catering to a wide array of industries. From light to heavy-duty applications, MATO's solutions encompass belt maintenance, cleaning systems, and conveyor belt components, serving virtually every sector where conveyor systems and belts are utilised.

MATO Australia produces Conveyor Belt Cleaning systems locally in Newcastle, NSW, catering to the global market. 30% of our belt cleaner business is exported worldwide through the MATO network of sister companies, making MATO a key supplier of Belt Maintenance Equipment worldwide.

At MATO, ensuring uncompromising quality is paramount. Our products are integral to safety-related applications, especially in environments like underground mines where conveyor systems play a critical role in transporting personnel and materials. Our rigorous quality assurance protocols, spanning the entire supply chain to product dispatch, adhere to a zero-error principle. Every employee at MATO shares the responsibility for maintaining these high standards, with suppliers seamlessly integrated into our quality management system.

Belt maintenance equipment

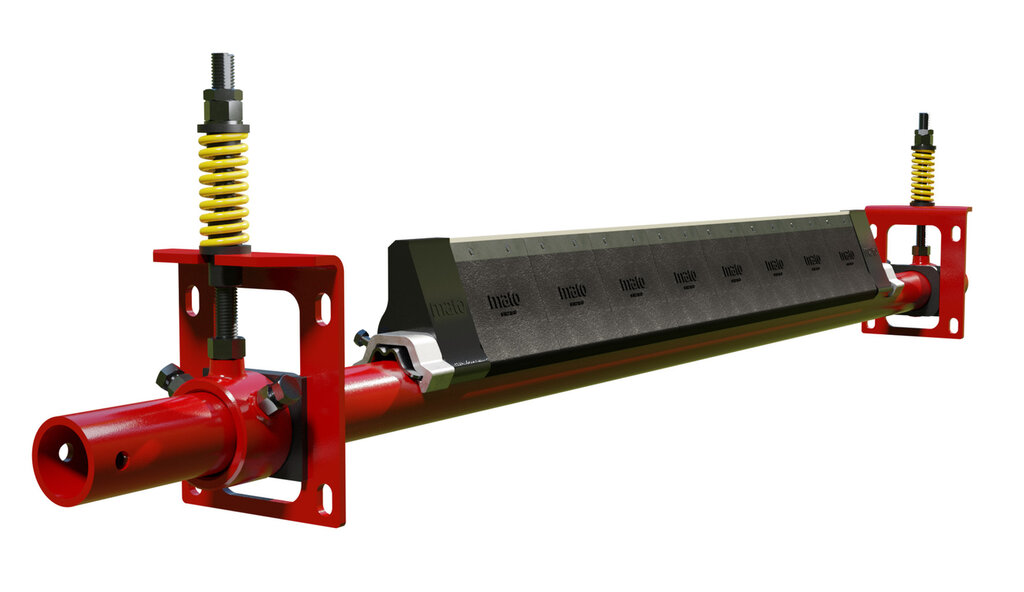

MATO stands at the forefront of mechanical conveyor belt splicing technology, offering a comprehensive range of belt maintenance equipment. Designed to work seamlessly with MATO fasteners, our belt cleaning systems complete the product suite. Applications for these products span diverse industries, including mining, agriculture, recycling, airports, and the food and textile sectors.

MATO fasteners are engineered to withstand demanding operational conditions, providing operators in coal mines and processing plants with the assurance of safely moving thousands of loads daily. The synergy between fasteners and cleaners is critical to the effective, safe, and economical functioning of conveyor belts. MATO belt cleaners excel in delivering efficient cleaning performance, extended service life, and easy maintenance, enhancing the overall performance of conveyor systems.

Primary and secondary belt cleaners

Installation of primary and secondary belt cleaners plays a pivotal role in optimising conveyor system performance.

Primary belt cleaners, available in tungsten carbide for vulcanised conveyor systems and polyurethane for systems with mechanical fasteners, effectively remove bulk material flow from the conveyor, reducing carry-back material and minimising spillage.

Secondary belt cleaners, also offered in tungsten carbide variants, are positioned behind the head pulley to tackle sticky, fine, or wet materials that primary cleaners may not address. Multiple secondary cleaners can be installed for extreme applications, ensuring thorough cleaning and mitigating the risk of belt mis-tracking and component wear.

Caption. Credit:

Contact information

MATO Australia Pty Ltd

39 Bonville Avenue,

Thornton NSW 2322

Tel.: +61 1300 850 795

Fax: +61 (2) 4936 1388

Email: maus@mato.com.au

Web: www.mato.com.au