Company Insight

Sponsored by myosh

Revolutionise safety: How myosh's Critical Control Management sets the new standard in risk prevention

From identifying critical controls to real-time monitoring with the Digital Bow-Tie framework, myosh empowers organisations to shift from mere compliance to proactive, integrated risk management.

Main image credit:

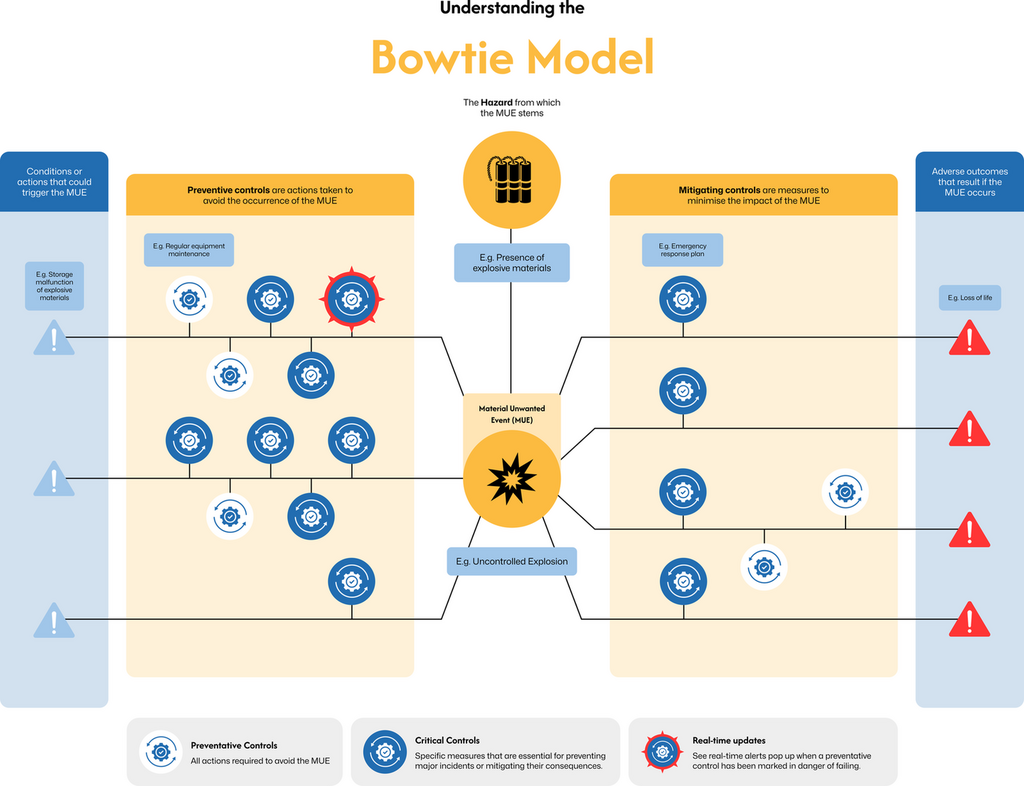

Critical Control Management (CCM) is a structured approach that focuses on identifying and managing the most crucial controls—known as critical controls—to prevent significant health and safety incidents, referred to as Material Unwanted Events (MUEs). myosh’s Critical Control Management module sets the standard in HSE management by offering a comprehensive solution that not only manages high-stakes risks but integrates seamlessly with day-to-day operations, making it a must-have for organisations committed to safety excellence.

What is Critical Control Management (CCM)?

Critical Control Management refers to complete strategy aimed at preventive steps designed to mitigate or prevent serious incidents within a particular industry or workplace. The core of this is implementation of controls, and particularly critical controls, for identified threats and possible consequences.

For example, these measures could include installing safety equipment, implementing specific operational procedures, or establishing guidelines to reduce risks associated with a Material Unwanted Event (MUE).

When is CCM important for organisations?

Some organisations, like mining enterprises, are required by law to have a system for implementing and monitoring critical controls in certain jurisdictions. However, aside from compliance, any organisation that faces the possibility of MUEs should have a strategy in place for keeping track of which control measures are critical for risk reduction, and continually verifying the integrity of these controls.

How can organisations start their CCM implementation?

myosh recommends an intuitive pathway for organisations to enter their CCM cycle:

- Identify Critical Risks: Utilise internal data and learning teams to pinpoint key risks and their associated controls.

- Define Critical Controls: Determine which controls are essential for preventing MUEs.

- Set Performance Standards: Establish measurable expectations for the effectiveness of these controls.

- Integrate into Daily Operations: Embed critical control verification into routine processes like inspections and observations.

- Monitor and Improve: Use performance dashboards to track control effectiveness and make ongoing adjustments.

What is myosh’s approach CCM implementation

myosh’s digital framework is a game-changer for interactive risk management pathways. It dynamically highlights any compromised controls and integrates control verification into daily tasks, providing unprecedented real-time transparency. Organisations benefit from automated notifications for compromised controls, compliance tracking through dashboards, and a heightened level of accountability across all levels.

What are the latest advances in CCM capabilities?

A useful paradigm for navigating the CCM workflow is the Plan-Do-Check-Act cycle. Over the last two decades, a popular tool that has emerged to aid in the Plan phase is the Bowtie Diagram. myosh has been developing a cutting-edge integrated software system specifically for navigating the full Plan-Do-Check-Act cycle, culminating in the ‘Digital Bowtie’.

In contrast to a typical static diagram, myosh uses the bowtie as a graphical interface that interacts with all the underlying records relevant to your CCM strategy. These include the central record describing the MUE and its risk rating, records of preventative/mitigative controls, and records describing upstream causes and downstream consequences.

Most importantly, it also connects control statuses with field inspections by generating verification records based on configured inspection response triggers.

A bow-tie diagram provides a visualisation of the relationship between initiating causes, preventative controls that reduce their probability of triggering the MUE, and the mitigating controls that reduce the severity of the potential consequences.

Finally, the system has been designed to be configurable without code-based programming. With minimal training, any safety manager is at all times able to modify the parameters and triggers of the system – which is critical for speeding up the responsiveness of the CMM cycle.

What role do operational leaders play in CCM?

Operational leaders set the tone for the importance of critical controls. By connecting leaders with real-time data and automated alerts, myosh encourages leadership involvement and helps them

- Apply controls effectively by providing a low-friction feedback mechanism,

- Model safety behaviours using structured forms and workflows,

- And support teams in understanding and adhering to safety standards by enabling role-based actions and accountabilities.

Interactive and configurable cloud-based platform that allows all stakeholders to participate in the CCM strategy.

Do you have any case studies?

Mitchell Services, a leader in drilling services, leveraged myosh’s Digital Bowtie framework to revolutionise its approach to safety and risk management. By implementing myosh’s CCM module, Mitchell Services reported the ability to:

- Engage crews directly in safety processes, making them active participants in risk management.

- Integrate control verification into daily work routines, facilitating real-time feedback from supervisors.

- Customise controls based on site-specific risk profiles, enhancing relevance and effectiveness.

- Increase transparency and communication, giving workers a “voice” in reporting safety concerns.

This innovative approach not only improved safety outcomes but also fostered a culture of active engagement and accountability throughout the organisation. By choosing myosh’s cutting-edge CCM tools, Mitchell Services demonstrated the powerful impact of adopting a proactive, integrated approach to Critical Control Management.

Click here to download a Critical Control Management Bowtie Guide PDF.

Caption: