Specialist Attachments Maximise Productivity in Tailings Applications– Movax Sheet Piling & Misu Screening Buckets

Sheet and tube piling has traditionally been used to stabilise the walls of tailings dams in mining applications to prevent dangerous slippage and subsidence.

Scroll down to read the article

Premier Rock Machinery is the regional dealer for the Movax range of excavator mounted piling equipment. Renowned for their high productivity and world class build quality – the Movax range of Excavator attachments are the optimum solution to handle, pitch, drive and extract piles without the need of manual handling or additional machinery. The use of MOVAX’s side grip technology in these applications leads to higher productivity, significant cost savings and significant safety advantages.

This technology is to be used in a tailings dam application at a mine in Papua New Guinea, and Premier Rock Machinery will proudly support the installation, commissioning and training on site in PNG.

- Damaged wall section can be easily removed and replaced

- Depths of 50 to 100 ft can be reached depending on conditions and equipment

- Installation is very rapid when compared to other types of cutoff wall construction

- These walls have high strengths which is ideal for durability or if any type of reinforcement is required

- Little to no waste materials are generated during construction

- In Tailings Applications - Fluid transfer through means of diffusion is greatly reduced

Sheet pile walls are fairly easy to install and do not require any previous excavation. Interlocking sheet piles, typically made of steel, are simply inserted into the ground one by one. The piles are either driven or more commonly vibrated to the necessary depth. For greater depths, additional piles are simply welded to the piles already inserted into the ground. If sealable joints are used, the joint cavities are flushed of all soil and debris and then a sealant is injected into the cavity.

Due to their easy and fast installation, but limited depth reach to about 30 m, sheet piles are often used as temporary barrier during construction in water like harbor and bridge foundation construction, but can be re-used several times. In areas with limited space, sheet pile walls are quite common for flood water protection in dikes or instead of dikes.

sheet piles are often used as temporary barrier during construction in water like harbor and bridge foundation construction

sheet piles are often used as temporary barrier during construction in water like harbor and bridge foundation construction

The Movax Range – As used in Tailings Applications

Misu, the original manufacturer of mobile screening technology in Australia is now proudly owned by Premier Rock Machinery (QLD).

In a reclaimed tailings paste plant application in Western Australia the MISU Screening Bucket is used to remove foreign material and break-up consolidated lumps of tailings.

The MISU uses a spinning rotor system to screen the material and will also crush the softer consolidated tailings. This method of screening has proven very successful and cost effective on tailings as it is able to handle very moist material and also the amount of oversize is limited since the lumps of tailings are crushed.

Misu, the original manufacturer of mobile screening technology in Australia is now proudly owned by Premier Rock Machinery (QLD).

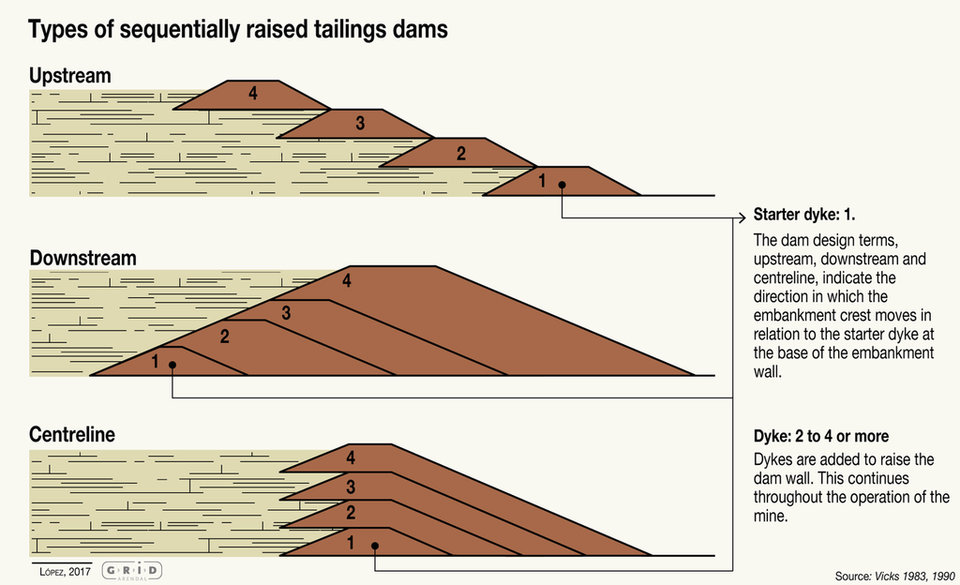

Tailings dam wall types where sheet piling is used

for stabilisation

Contact information

Premier Rock Machinery

Unit 4 / 30 Gardens Drive, Willawong, QLD 4110

Web: www.premrock.com.au

Email: prm@premrock.com.au

Phone: +61 7 3711 2779

Fax: +61 7 3711 2778