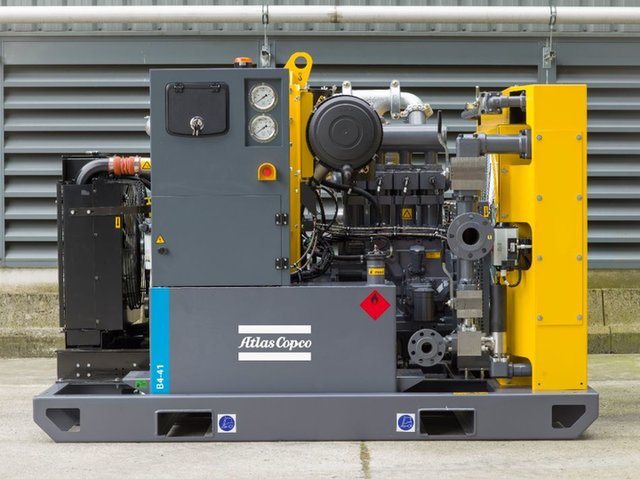

BOOST YOUR PRODUCTIVITY with the Atlas Copco Booster Compressor.

When we talk about high pressure boosters, we simply mean a compressor which enables you to step up the pressure of the

primary feed air compressor. If you require air or nitrogen at any pressure between 69 and 345 bar, Atlas Copco’s high pressure booster with unique in-house designed pumper block is the most efficient choice. They are designed to be transported to your point of work – no matter how remote the location. Whether you are in rental, service industry or water well drilling; this portable booster is the best solution for your needs.

1 to 4 compression stages

Flows up to 127m3/min

Solutions up to (5000 psi)

Efficiency and productivity

Our boosters further increase pressure ratio of air or nitrogen by approximately factor 2.7 and 2.9 per compression stage (up to 3 stages available). The integrated fuel tank autonomy further improves ease of use.

Versatility and profitability

Through the new Xc4004 Smart air controller, the required output pressure can easy be defined with a touch of the button. You determine the pressure, while your application dictates the flow. For example in a drilling application, drilling speed can efficiently be increased, reducing the cost per meter drilled and improving your overall profitability.

Serviceability

Our pumperblock design not only efficient and small, it is also easy to maintain. The standard components don’t require special oils and all service points are easily accessible. A booster can be maintained by one service technician without the need for a crane or special tools within 4 hours.

Transportability

- Our in-house pumperblock design allows for a unique set-up of all booster components, greatly impacting the footprint of the high pressure booster. Even a 4.4m2 booster can boost gas up to 69 bar.

- This small footprint limits transportation costs as both the booster and feed air compressor can be combined on one trailer.

- With the weight as low as 2950 kg, even demanding offshore applications experience no limitations.

Safety

Our state-of-the art Xc4004 controller is constantly monitoring all vital parameters of the booster. In case of pending failure, the controller will protect your investment by automatically shutting down and thus avoiding damage to core components.

Smart air controller

- A clear 7 inch screen with all key parameters at first glance.

- Access to historical data.

- Remote controlling

- With this controller, your booster is ready for the future.

BOOST YOUR PRODUCTIVITY with the Atlas Copco Booster Compressor.

When we talk about high pressure boosters, we simply mean a compressor which enables you to step up the pressure of the

primary feed air compressor. If you require air or nitrogen at any pressure between 69 and 345 bar, Atlas Copco’s high pressure booster with unique in-house designed pumper block is the most efficient choice. They are designed to be transported to your point of work – no matter how remote the location. Whether you are in rental, service industry or water well drilling; this portable booster is the best solution for your needs.

1 to 4 compression stages

Flows up to 127m3/min

Solutions up to (5000 psi)

Efficiency and productivity

Our boosters further increase pressure ratio of air or nitrogen by approximately factor 2.7 and 2.9 per compression stage (up to 3 stages available). The integrated fuel tank autonomy further improves ease of use.

Versatility and profitability

Through the new Xc4004 Smart air controller, the required output pressure can easy be defined with a touch of the button. You determine the pressure, while your application dictates the flow. For example in a drilling application, drilling speed can efficiently be increased, reducing the cost per meter drilled and improving your overall profitability.

Serviceability

Our pumperblock design not only efficient and small, it is also easy to maintain. The standard components don’t require special oils and all service points are easily accessible. A booster can be maintained by one service technician without the need for a crane or special tools within 4 hours.

Transportability

- Our in-house pumperblock design allows for a unique set-up of all booster components, greatly impacting the footprint of the high pressure booster. Even a 4.4m2 booster can boost gas up to 69 bar.

- This small footprint limits transportation costs as both the booster and feed air compressor can be combined on one trailer.

- With the weight as low as 2950 kg, even demanding offshore applications experience no limitations.

Safety

Our state-of-the art Xc4004 controller is constantly monitoring all vital parameters of the booster. In case of pending failure, the controller will protect your investment by automatically shutting down and thus avoiding damage to core components.

Smart air controller

- A clear 7 inch screen with all key parameters at first glance.

- Access to historical data.

- Remote controlling

- With this controller, your booster is ready for the future.

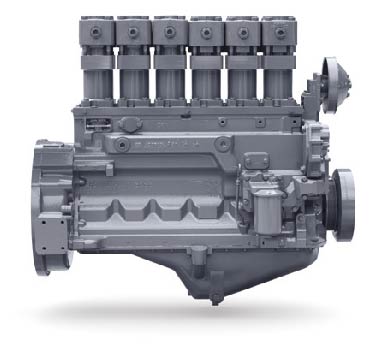

Maximum pressure at minimum footprint

Our unique pumperblock design impacts the footprint significantly.

Less piping, a more clean lay out and standard components also improve the serviceability. Service can be done by 1 technician, without the need for a crane or special tools, in under 4 hours.

Versatility is key

The new controller allows to set the pressure with the touch of a

button, while the modular pumperblock design increases utilization

rate as all 2 stage models can also be switched to a single stage set-up.

Versatility

All boosters are standard equipped with both pre and after-coolers;

making them compatible with any air compressor as feed air.