Company Insight

Sponsored by Batt Mobile Equipment Pty Ltd (“BME”)

BME's Battery Electric Mobile Equipment Solutions: Enhancing Safety, Zero Emissions, and Cutting Operating Costs

Batt Mobile Equipment (BME) is an Australian Original Equipment Manufacturer that specializes in the development of battery electric vehicles (EVs) for mid-sized equipment, such as their 20 tonne fully electric wheel loader.

BME achieved a significant milestone in 2020 by completing their first conversion of a Volvo 120E Loader.

Being Australian owned, engineered and manufactured, BME prides itself on producing premium high-quality fully electric equipment at cost effective prices.

The initiative to develop battery electric equipment was driven by BME’s relationship with Cougar Mining Group (CMG) in 2016 and thereafter the Australian Electric Mining Consortium in 2021. The mining industry faced mounting pressure to reduce its environmental impact, leading to the need for more sustainable solutions like electric mining equipment.

BME’s commitment to being "Australian engineered and manufactured" and "100% Australian Owned" showcases the dedication and effort invested in the project, reinforcing its national origin and the pride in contributing to the Australian mining sector.

BME is building on proven technology to facilitate companies in adopting EV (Electric Vehicle) technology at affordable prices, offering a range of benefits that improve safety, the environment, and productivity.

BME’s 20-tonne Integrated Tool Carrier and 6-tonne rated load capacity Wheel Loader are designed to deliver optimal performance.

The machines feature a fully sealed A/C cabin, ensuring operator comfort and protection. Safety is prioritized with ROPS/FOPS Certified Cabin, providing a secure environment for operators in challenging mining conditions.

Quick hitch system enhances operational efficiency by enabling swift attachment changes. Use of Li-Ion KREISEL (John Deere owned) battery pack, with a 730V nominal voltage, ensures extended operation without emissions or diesel particulates. Patended KREISEL Electric Immersion Cooling Technology offers superior safety and performance, maximizing battery life.

Additionally, BME's EVs support Combined Charging System (CCS2) compatibility, facilitating Ultra Fast EV Charging at up to 125kW. This allows for approximately one-hour charge time, enabling efficient and rapid battery replenishment.

By combining affordability with advanced technology, BME paves the way for companies to embrace sustainable and efficient mining practices. With reduced noise, maintenance, and ventilation requirements, along with increased speed and reliability, BME’s EV equipment delivers compelling reasons for the mining industry to transition towards greener and cleaner operations.

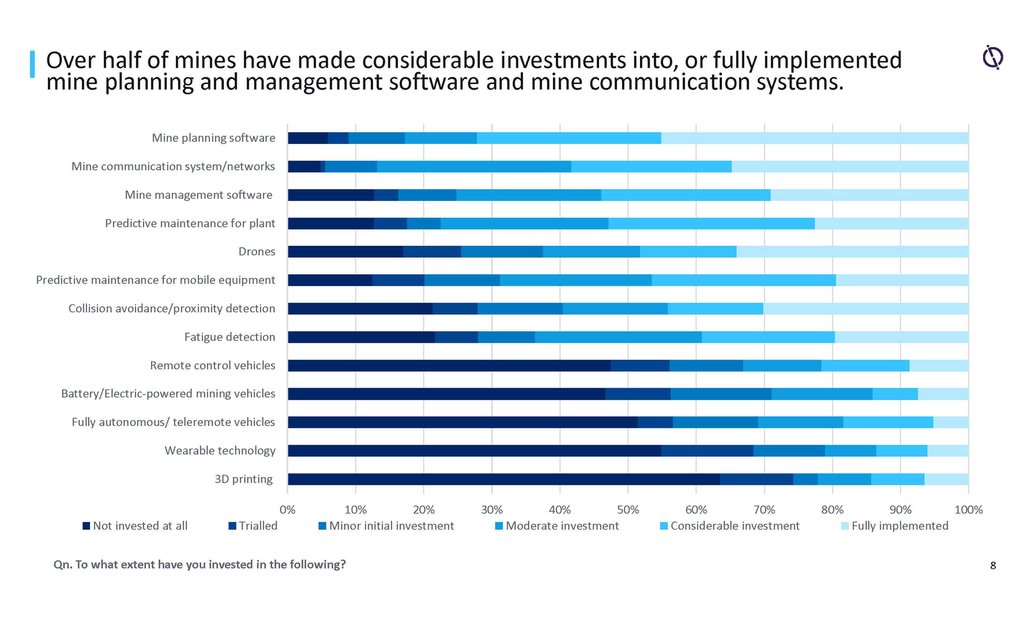

Source: GlobalData: Global Mine Site Technology Adoption survey report 2023

Variations across regions included a high share of mines in Australia expecting to invest more in predictive maintenance for mobile equipment and collision avoidance and 44% of respondents from Asia-Pacific also expected to invest in battery/electric vehicles in the next two years.

What are the features and benefits of Electric LDV’s?

Here is a list of five key reasons to switch to Electric LDV’s

- Significant Reduction in Underground Mine Ventilation Cost: Electric LDVs and trucks require 40-50% less ventilation compared to diesel units. This reduction in ventilation needs leads to cost savings and improved energy efficiency within the mine.

- Lower Cooling Requirement: Electric equipment generates 20-40% lower heat losses compared to diesel units, resulting in decreased cooling requirements, and improved thermal management within the mine.

- Lower CO2 and Heat Emissions: Electric equipment produces lower CO2 and heat emissions, leading to improved air quality and a healthier working environment for operators and miners.

- Lower Maintenance Costs: Electric machines generally have lower maintenance costs compared to similar diesel-operated equipment. This translates to reduced downtime and increased operational efficiency.

- Lower Noise Pollution: Electric underground loaders and mining trucks operate more quietly compared to diesel-powered units, reducing noise pollution in the underground working environment. This leads to a more comfortable and productive working environment for miners.

Overall, the adoption of Battery Electric Vehicles trucks represents a promising shift towards more sustainable and environmentally friendly mining practices, offering tangible benefits in terms of cost savings, efficiency, and improved working conditions.

Contact information

Batt Mobile Equipment Pty Ltd

Workshop: 12-14 Martin Drive,

Tomago, NSW 2322

Postal: PO Box 385 Beresfield,

NSW 2322

Tel.: +61 2 4028 0400

Email: bmesales@battmob.com.au

Website: battmob.com.au