Company Insight

Sponsored by Geographe

Empowering Mine Sites with Enhanced Performance Parts for Optimised Operations

Click to edit...

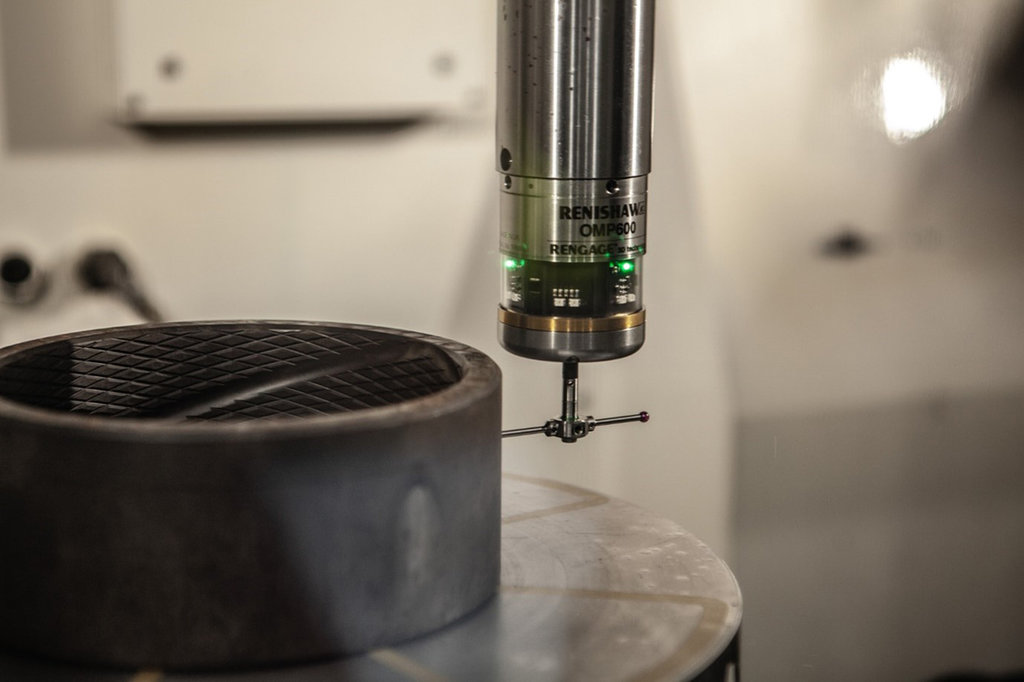

Main image credit:

In response to mining companies' unwavering commitment to safety and preventing potential hazards, Geographe’s Enhanced Performance (EP™) Parts provide significant solutions in elevating maintenance practices. These custom-designed and precision-manufactured parts result from extensive research, design, and collaboration with clients, saving miners and off-site repairers from an array of safety and production impacts caused by underperforming equipment components.

Geographe's EP™ Parts go beyond being a machine part number. They symbolise the culmination of dedicated work by the Geographe team to refine and perfect their design and performance, ensuring optimal results for their clients. Through the use of advanced materials, innovative designs, and rigorous testing, EP™ Parts can exhibit superior resistance to wear, corrosion, and impact. As a result, they effectively tackle the common challenges encountered in mining operations.

Caption. Credit:

Cost-Effective Solutions and Reduced Downtime

Designed to outperform original components, EP™ Parts are engineered to deliver unparalleled reliability, safety, and efficiency to mining fleets, redefining mine site processes globally.

Through the use of innovative materials and advanced manufacturing processes, EP™ Parts can outperform OEM components for heavy machinery, leading to longer periods between maintenance cycles and increasing fleet efficiency. By reducing machine downtime, these high-performing parts help mine sites to increase their savings on their operations.

With over 1,000 parts in its portfolio, Geographe’s EP™ range can provide your site with tailored, cost-effective solutions.

Caption. Credit:

Innovating Performance: EP™ Pin Assemblies & Kits

Geographe offers a variety of EP™ Parts to suit machines manufactured by Caterpillar, Komatsu, Liebherr, Hitachi and more. Among them, the EP™ Pin Assemblies for the Caterpillar 7 Series and Komatsu 830E & 930E Haul Trucks stand out as a cost-effective solution to hot works during maintenance.

EP™ Greaseable Hoist Pin Assembly

One remarkable offering is the EP™ Greaseable Hoist Pin Assembly, which can be greased through the truck's auto lubrication system. This innovative approach not only enhances the safety of the maintenance process but also ensures efficient pin extractions.

EP™ Colleted Pin Assembly

This assembly eliminates the need for tyre handling, a task that often involves hot work. The elimination of such practices not only enhances safety but also saves valuable time and resources. With no further machining needed on the lower stepped bore, this assembly boasts complete interchangeability, facilitating full oscillation and movement.

Caption. Credit:

Enhancing Safety and Efficiency in Maintenance Events

Maintenance procedures in mining operations frequently expose personnel to safety hazards. This prompts mining companies to seek safer alternatives to protect their employees' well-being.

Geographe's EP™ Parts play a pivotal role in achieving this goal by offering alternatives to hazardous practices such as thermal lancing or hot works. This reduction in dangerous practices can lead to substantially fewer injuries, subsequently leading to significant cost savings over time.

Optimised Operations for Superior Performance

Geographe's Enhanced Performance (EP™) Parts mark a significant advancement in the mining industry. These parts not only enhance the performance of mining equipment but also contribute to a safer working environment. Through continuous innovation and collaboration, Geographe has carved a distinctive niche by providing solutions that elevate mine site operations and empowering mining companies to achieve new levels of safety and efficiency.

Contact information

Geographe

480 Abernethy Road,

Kewdale WA 6105

Tel.: + 61 8 9449 1111

Email: sales@geographe.com.au

Web: www.geographe.com.au