Replacing faulty cables is not a manual process anymore

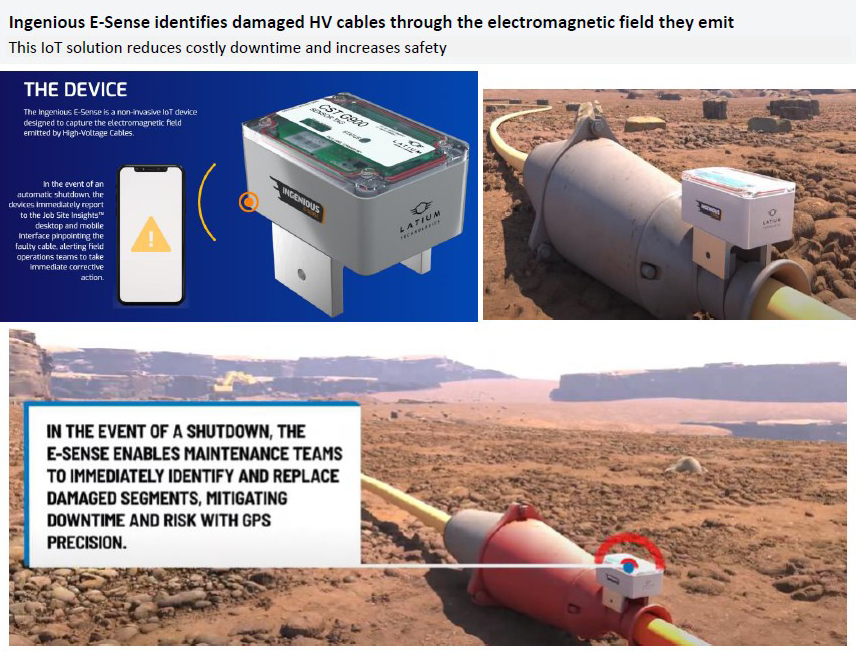

Latium Technologies is an IoT solutions provider for the construction, mining, and oil and gas industries. In 2021, the company launched the Ingenious E-Sense device, an IoT sensor that monitors the interconnected networks of high-voltage (HV) cables in mining sites.

The device is non-invasive and allows for a rapid response in case of automatic shutdown, locating the damaged or faulty areas. It works by capturing the electromagnetic field emitted by the HV cables, using GPS-equipped sensors to log the location of the drop in power and transmit the signal up to 30km.

This solution reduces time and increases safety, as identifying damaged cables has always been a manual process requiring interaction with hazardous charged cables, hours of downtime, and thousands of dollars in lost productivity.

Credit: Latium Technologies

A safe and accurate LiDAR mapping device for challenging mining sites

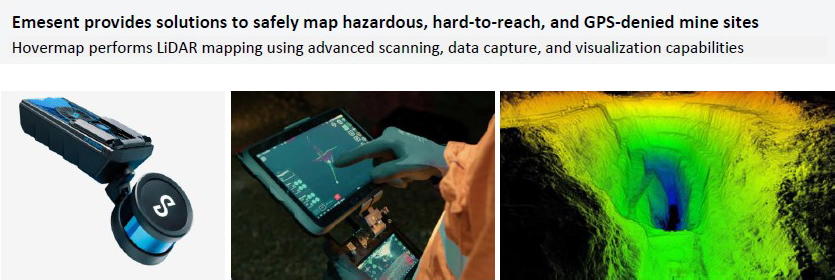

Emesent is a LiDAR mapping and data analytics solutions provider that aids the mining, engineering, and public safety sectors in their operations. Mining exploration is notoriously challenging, especially in underground environments that are hazardous, hard to reach, and often GPS-denied.

Mapping is paramount to ensure reasonable survey-grade results or calculate the volume of mine materials. Accurate mapping of either ground or underground sites is required, as well as the efficient analysis and processing of the acquired data.

Hovermap is Emesent’s core product, a mobile autonomous LiDAR mapping device using advanced scanning, data capture, and visualisation capabilities. Hovermap can be deployed on a drone, allowing mining companies to capture and visualise an accurate and up-to-date representation of a surveyed environment. These are often dangerous environments, such as slopes or vertical shafts.

Also, using the Hovermap app, it is possible to see the preview of a live point cloud during data acquisition. Hovermap enhances efficiency, given its ability to capture data voids and drift up to 75% faster than previous methods like cavity monitoring systems (CMS).

In a conversation with GlobalData, Stefan Hrabar, CEO and co-founder of Emesent, said: “Hovermap is a hardware and software combination. It combines the LiDAR technology with an onboard computer designed to process all the data. It's designed to be a versatile plug-and-play mapping and autonomy payload. It can be mounted on a drone, connected to it, and makes the drone autonomous. It can be carried by hand or put on a robotic dog, making the dog autonomous.

“Hovermap has this versatility aspect…as the mapping and the autonomy are blended in one device which can be used in mines for a range of use cases.”

Emesent collaborates with mining companies such as Rio Tinto, BHP, South32, Glencore, and Anglo American. High-resolution data allows for accurate volumetric calculations and more confident decision-making, reducing production delays and operating costs. Identifying safety hazards and unsafe structural conditions makes the mine site safer.

When asked about the ROI for mining companies using Emesent’s solutions, Hrabar said: “The value of our products is seen when there is something that has gone wrong, like a seismic event where rocks have collapsed, and mines have to shut down production.

“In such a scenario, they can use Hovermap to go in and map the area, assess how much damage there was, and whether it's safe to go in. Usually, that would take them weeks or months because they have to go in very slowly. But using our technology, they can quickly reopen production as if they can get the data, they can sort out the issues and continue the production.”

Credit: Emesent

ABB’s VOD system reduces energy usage and ensures a healthy working environment

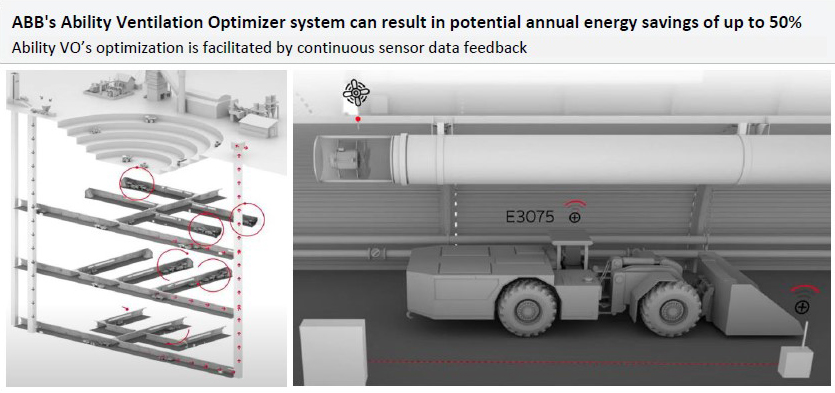

Ventilation on demand (VOD) systems provide fresh air while removing contaminated air, maintain a comfortable temperature for workers, and prevent exposure to harmful substances like carbon monoxide (CO), carbon dioxide (CO2), dust, humidity, and nitrogen dioxide (NO2) emissions from diesel vehicles. However, high energy costs due to the system's energy-intensive nature and declining ore quality require advanced ventilation technology in remote mining locations.

ABB's Ability Ventilation Optimizer (VO) addresses these challenges. It uses the System 800xA platform to collect real-time data from air quality and pressure sensors throughout the mine. This data includes truck usage, staff location, gas levels, airflow, and temperature. Using this information, the system optimises fan operation based on production schedules and equipment status, reducing air supply to specific mine sections by up to 40%.

The VO system comprises three implementation stages. In the first stage, the Ability VO is connected to the ventilation equipment, allowing customers to supervise and control fans and air regulators remotely. For example, they can adjust airflow in response to activities like blasting in the mine. The second stage involves automatic control of the ventilation equipment.

Tracking tools integrated into the mine systems monitor the precise locations of vehicles, machines, and workers based on the production schedule. The third stage focuses on mine-wide control and optimisation. This stage uses model predictive control (MPC) technology, which identifies the optimal parameters for regulating all fans based on demand. This optimisation is facilitated by continuous sensor data feedback.

ABB claims that its Ability VO system optimises airflows and air quality, resulting in potential annual energy savings of up to 50%. VOD technology generally offers mining companies benefits in terms of improved efficiency, reduced costs, and enhanced safety.

Credit: ABB

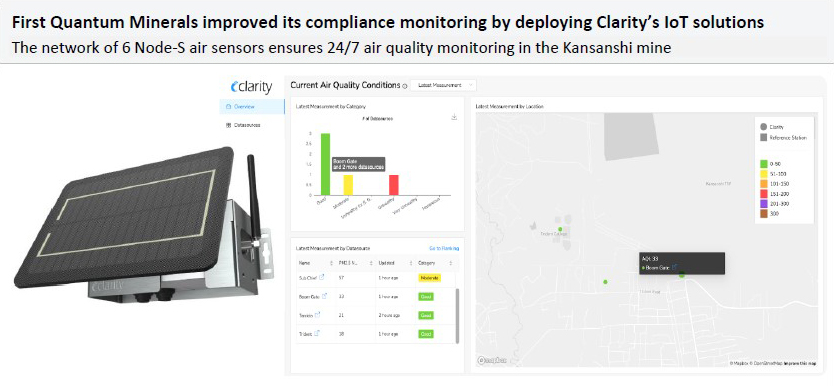

Clarity helps First Quantum Minerals to improve air quality compliance

Clarity is an air quality monitoring company founded in 2014. It uses air sensing technology, IoT devices, and data analytics to provide real-time air quality data to various sectors, including mining. Among its adopters is the copper mining company First Quantum Minerals.

Clarity helped the mining company to improve its compliance monitoring in the Kansanshi mine in Zambia. First Quantum Minerals deployed its first network of Clarity Node-S devices, particulate matter (PM), and NO₂ monitors at key compliance points around the mine. Among the benefits that the Kansanshi mine experienced was improved data accuracy thanks to the real-time and 24/7 monitoring. Maintenance time was reduced by 80%.

Credit: Clarity

Caterpillar enhances safety and communication with the Connected Worker system

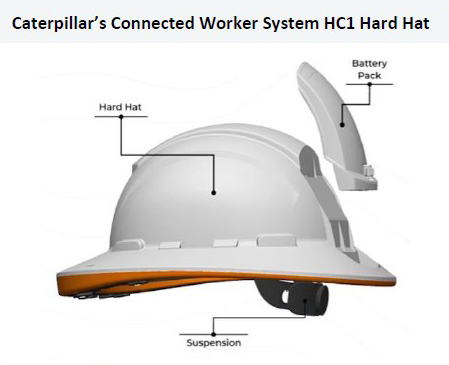

At the MINExpo 2021 in Las Vegas, Caterpillar launched the Connected Worker System HC1 Hard Hat, a Guardhat-developed piece of wearable tech that aims to make workers safe on surface sites.

The Connected Worker system consists of three main components: the wearable hardware, software to capture data and generate reports, and the IoT platform that receives field reports and alerts workers of potential safety issues. The hat comes with SOS, evacuation, and social distancing alerts and alerts workers of geofence breaches.

Connected Worker improves safety by alerting all connected workers of hazardous situations in real-time, delivering up to a 50% reduction in lost-time reportable incidents, claims Caterpillar. In addition, the system’s ability to track worker location and enhance communications through audio, video, and image transmission helps to increase mine site productivity.

Credit: Caterpillar

GlobalData, the leading provider of industry intelligence, provided the underlying data, research, and analysis used to produce this article.

GlobalData’s Thematic Intelligence uses proprietary data, research, and analysis to provide a forward-looking perspective on the key themes that will shape the future of the world’s largest industries and the organisations within them.