Company Insight

Sponsored by Geographe

A Collaborative Approach to Improving Maintenance Practices in Your Caterpillar Haul Truck Fleet

How often do you consider enhancing safety practices at your mine site?

Main image credit:

How often do you consider enhancing safety practices at your mine site?

In Australia, where mining practices must adhere to rigorous safety standards, the need for alternative maintenance solutions to dangerous procedures becomes particularly crucial.

Thermal lancing, a widely employed technique for removing worn or seized components, poses inherent risks, jeopardising worker safety through factors such as noise pollution, respiratory risks, severe burns, eye injuries, toxic fume emissions, and fire hazards.

Mining professionals such as yourself can play a pivotal role in steering safety practices within mine sites, where showcasing expertise and emphasis on the importance of strategic decision-making can effectively address safety challenges and enhance your site's safety practices.

Recognising the industry-wide challenges posed by thermal lancing and the escalating standard of workplace safety, Geographe offers Enhanced Performance Parts that are designed to boost safety and efficiency. This aligns with their ever-growing commitment to maintaining safe work practices.

Greaseable Hoist Pin

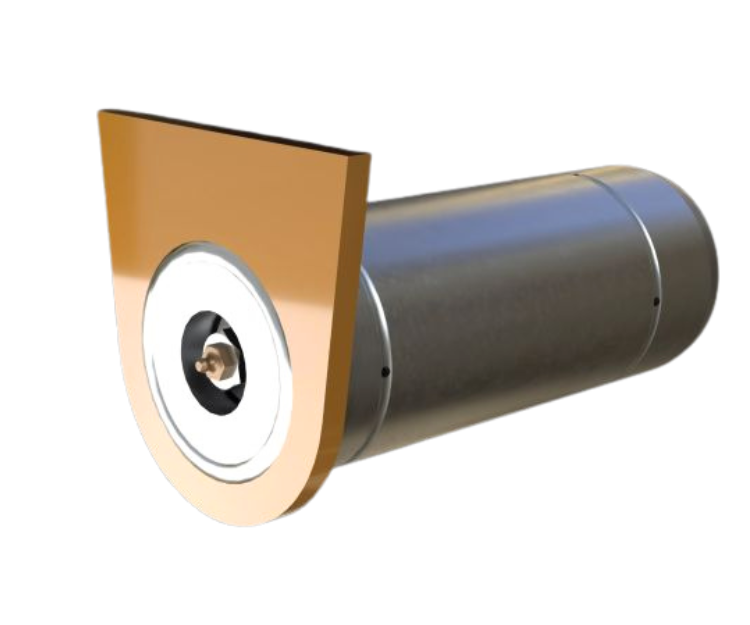

Geographe Enhanced Performance™ Greaseable Hoist Pin Kit

An Australian Tier 1 mining customer approached Geographe with a challenge related to the use of thermal lancing during the removal of the hoist cylinder pin on their Caterpillar haul truck fleet.

The challenge of using thermal lancing not only resulted in prolonged fleet downtime and extended changeouts but also generated excessive noise pollution within and beyond the work area. Maintenance personnel working near an operating lance were being exposed to noise levels well over 94 decibels for extended periods, which could be linked to permanent hearing loss. Further investigation also revealed that it took a single boilermaker up to 8 hours to remove the two pins required for one hoist cylinder pin.

In response, Geographe collaborated with the miner to introduce the Geographe Enhanced Performance™ (EP) Greaseable Hoist Pin, a solution designed to enhance standard hoist pins.

The EP Greaseable Hoist Pins are greased via the truck's auto lubrication system, improving the extraction process into a safer and more efficient practice, as well as significantly reducing bore damage observed after using thermal lancing.

As Australian mine sites continue to drive innovation and uphold safety standards, collaborating with safety partners like Geographe will continue to enhance mining practices.

As Australian mine sites continue to drive innovation and uphold safety standards, collaborating with safety partners like Geographe can help improve your mission of enhancing safety practices at your mine site.

Contact information

Geographe

480 Abernethy Road,

Kewdale WA 6105

Tel.: + 61 8 9449 1111

Email: sales@geographe.com.au

Web: www.geographe.com.au