Company Insight

Sponsored by CCG Cable Terminations

No loose ends

CCG’s Captive Component Glands® eliminate installation errors.

Main image credit:

For over 50 years, CCG has redefined safety in hazardous area installations, starting with the invention of the Captive Component Gland® in 1972. Developed in response to issues in deep-level mining, where loose components frequently caused installation failures, this innovative design eliminated the risks posed by traditional cable glands. Today, CCG’s products are trusted by industries worldwide, including Oil, Gas, Petrochemical, and Mining for their unmatched safety, simplicity, and reliability.

When it comes to hazardous area installations, one misstep can compromise the entire system. A common pitfall? Improperly specified or fitted cable glands. Thankfully, CCG’s Captive Component Glands® offer a reliable solution to ensure your Ex installation remains safe and compliant.

The risks of traditional cable glands

Most cable glands come with multiple components—cones, cone rings, seals—that must be perfectly assembled to ensure safety. However, mistakes happen; components can be misplaced, misaligned, or omitted altogether. The result is a compromised connection that jeopardises the Ex certification of your apparatus.

The CCG solution: Captive Component Glands®

CCG’s innovative Captive Component Gland® design eliminates these risks. With “Built-in Safety™” at its core, these glands feature no loose components. Every part is securely held captive, preventing assembly errors. The simplicity of the two-part design means that wherever in the world CCG products are installed, users can be confident that every component is properly fitted, safeguarding the entire system.

This unique approach ensures a reliable installation every time, making CCG the go-to choice for operators, system integrators, and OEMs.

Key advantages:

- Ease of Installation: Without loose parts, the glands are simple to assemble—even in unsupervised or remote locations where skilled labour may be limited.

- Global Confidence: The intuitive two-part system ensures correct installation anywhere in the world.

- Enhanced Certification Assurance: By minimising human error, Captive Component Glands® safeguard the integrity of your Ex certification.

A selection of our market-leading products

IPlus Corrosion Guard™

Designed for Steel Wire Armoured Cables, the IPlus Corrosion Guard™ is built for harsh, corrosive environments.

Features:

- Factory-fitted elastomeric seals for Built-in Safety™.

- Non-corrosive Corrosion Guard™, which screws onto the gland body and seals over the cable’s outer sheath for IP66/68 and deluge-proof protection.

- Precision-manufactured from high-quality brass with nickel plating for superior durability.

- Complete with a sealing gasket and heavy-duty locknut for secure installations.

Ex Corrosion Guard

Ideal for hazardous areas (Zones 1, 2, 20, 21, 22), this dual-seal gland excels in corrosive, wet environments.

Features:

- Freely rotating captive cone and inspectible cone ring for reliable armour clamping and earthing.

- Corrosion Guard® protection for the gland body and armour, delivering an IP68-rated seal.

- Made from Marine Grade Electroless Nickel-Plated™ brass for long-lasting performance.

- Supplied with a thread sealing gasket for easy assembly.

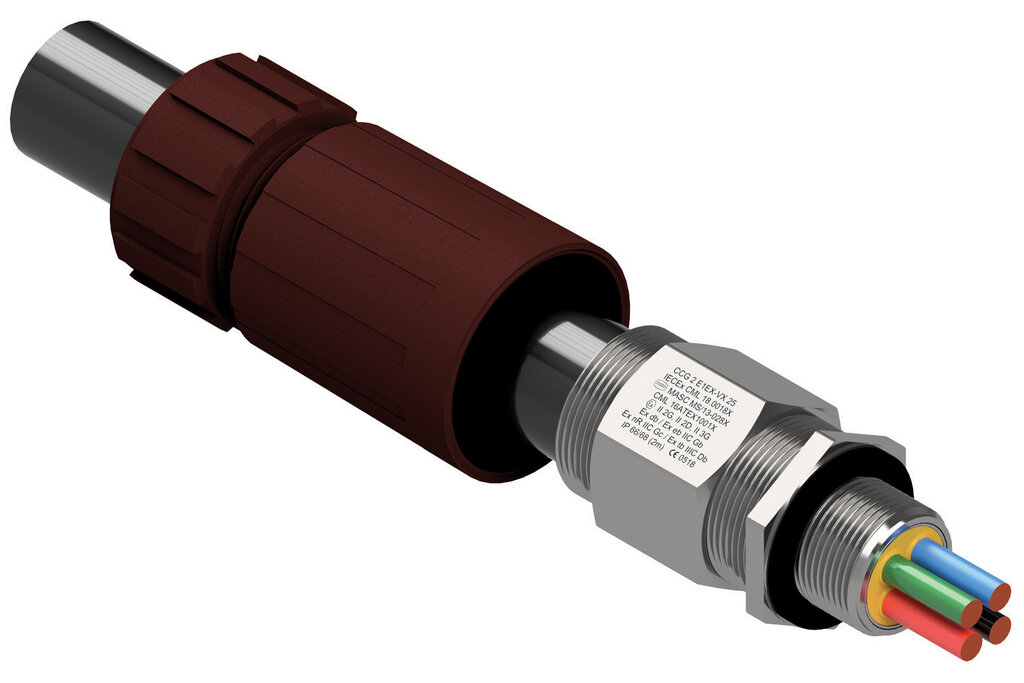

Ex Corrosion Guard VX (VORTEx)

Tailored for the most challenging conditions, the VORTEx model offers advanced protection for unfilled hygroscopic multicore cables.

Features:

- Dual-seal design prevents the transmission of explosive gases or liquids down the cable.

- Resin injection technology creates a 100% barrier seal around individual cable cores.

- Manufactured with precision using Marine Grade Electroless Nickel-Plated™ brass.

- Supplied with a parallel-thread sealing gasket for added security.

Global reach, local expertise

As the largest cable gland manufacturer in the Southern Hemisphere and a global leader, CCG operates cutting-edge CNC manufacturing facilities and maintains an extensive distribution network, including:

Australia: Brisbane, Townsville, Newcastle, Perth, Hobart, and Darwin.

New Zealand: Distributed through Transnet.

Additional hubs in Hong Kong, Singapore, South Africa, South Korea, the UAE, and the UK.

For safety-critical applications, there’s no room for error. CCG is the name engineers and industries trust to get the job done right, every time.

Simplify your installations. Strengthen your safety. Choose CCG.