Company Insight

Sponsored by Wilo Australia

Through rain and rubble

Wilo-Actun ZETOS takes on mining’s water woes.

Main image credit:

When it comes to mine dewatering, both climate change and the need for sustainability are posing fundamental challenges worldwide. An important role in meeting these challenges is played by application-specific pump solutions that combine maximum energy efficiency with the longest possible service life, even under challenging climatic and operating conditions.

Complex decision-making processes occur when balancing economic efficiency, functionality, and reliability, especially in an environment with extreme operating conditions, as is the case with dewatering pumps in underground and open cut mining. The design and operation of the Wilo-Actun ZETOS pump series are consistently aligned to provide a solution to key problem areas. Particularly due to:

- Robust design resulting in longer running time

- High energy efficiency (best-in-class) making the solution economical

- Application-specific design for full flexibility

The fundamental challenges

The issue of dewatering not only involves the ground water that is produced during the excavation process, but also the process water and any rainwater that may flow in. As a result, the dewatering process is subject to quantitative influences that are difficult to predict, which must be reacted to according to the situation. This is particularly true in regions like Western Australia, where heavy localised rainfall can lead to significant short-term changes in how mine dewatering systems are operated.

Further challenges arise from the environmental conditions. For example, if the water is contaminated with considerable amounts of abrasive and corrosive or adhesive elements (such as sand, iron oxide, salt, chloride, or sulphate). These elements in the water have the potential to affect the performance and service life of the pumps.

On top of everything, climatic conditions place high demands on the mines' water management systems. While outside temperatures of -20°C are frequently measured in the Arctic Circle when mining copper ore, on the other side of the globe, in Western Australia, weeks-long heatwaves keep daytime temperatures at 45°C or more. The water needing to be pumped reaches temperatures of 30 to 35°C.

Another challenge is the remote location of most mines. Any operational disruptions cause significant corresponding downtimes due to lack of accessibility of replacements. In extreme cases, a total halt of all mining operations can result in losses running into the millions. For this reason, it is essential that the pumps are low maintenance and reliable.

Wilo-Actun ZETOS series

The German designed and engineered modular Wilo-Actun ZETOS pump series provides mine operators with a range of deep-well pumps for dewatering, which overcomes the fundamental challenges of mining and support the journey towards more sustainable solutions. The high efficiency of the pumps, combined with significantly longer service lives compared to conventional pump solutions, contribute directly to reducing energy consumption. At the same time, they minimise operational disruptions due to their reliability and availability of parts in Australia with local assembly.

Caption. Credit:

The advantages of the Wilo-Actun ZETOS:

1. Covering all your needs

- Three nominal sizes available: 8 inch, 10 inch, 12 inch

- Max. volume flow: 765 m³/h

- Max. delivery head: 640 m

- Max. fluid temperature: 70 °C

- Motor sizes from 5.5 kW (6’’) up to 580 kW (16’’)

- Flanged or Threaded discharge with or without inbuilt non-return valve

2. High degree of robustness enables longer running times

- High reliability as a result of the particularly corrosion-resistant bare shaft pump made completely of stainless-steel investment casting 1.4408 with corrosion properties comparable to AISI 316

- Version in 1.4517 (duplex) option available

- Innovative design enables wear resistance up to a factor of 3 times higher than conventional pumps (sand content of up to 150 g/m3 (K8,10) and 100 g/m3 (K12))

- High manufacturing quality makes the pump particularly durable

- Internal active cooling provides maximum motor service life

- Optional Ceram CP coating prevents deposits and extends maintenance intervals

3. High level of energy efficiency makes the pump more economical

- Permanent magnet motors with best-in-class efficiency of up to 94%

- Highest hydraulic efficiency of up to 86%

4. Modular construction and local availability

- Just-in-time local assembly

- Ease of repair

Caption. Credit:

Maximising sustainability and efficiency

Mine operators are subject to public pressure to drastically reduce the negative environmental impact of their activities. As a result, the energy needed for pump operation is increasingly becoming a focal point. In many regions of the world there is no public power grid available for operating dewatering systems at mines due to their locations far away from any infrastructure. Instead, diesel-powered generators are mostly used, which worsen the mine's ecological footprint due to their emissions.

Shiploader at the Port of Burnie, Tasmania.

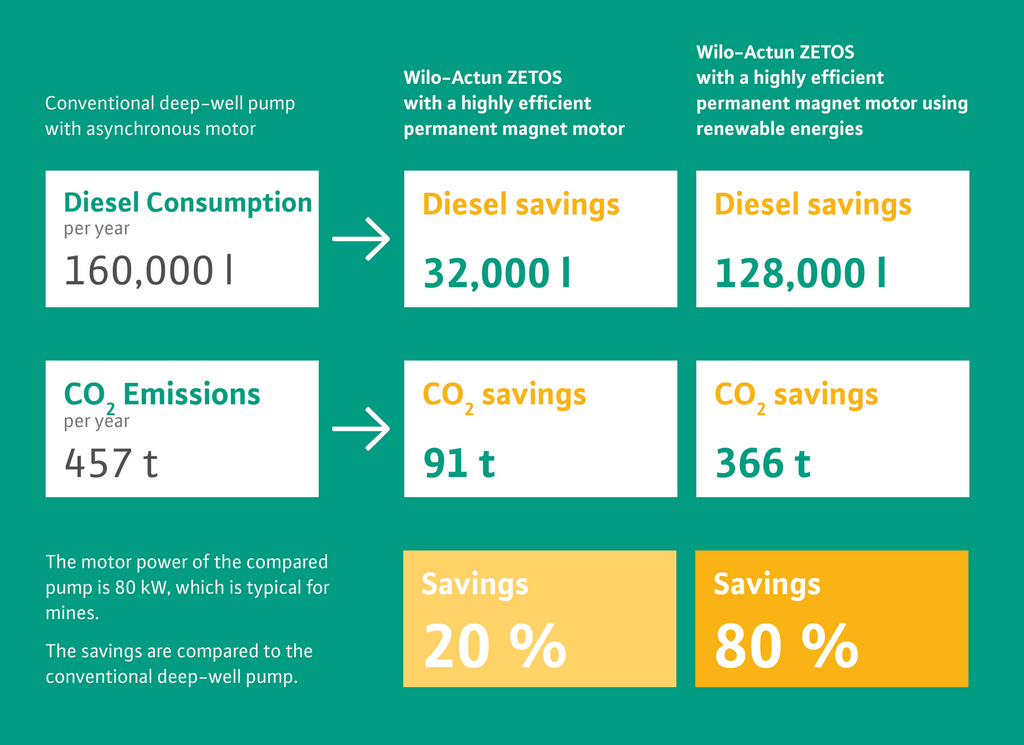

According to the calculations by our partner UON Pty Ltd, a company specialising in decentralised water and energy solutions in Western Australia, it's necessary to pump out more than one billion cubic metres of water each year from the open cut mines in the area and return a considerable amount of this to the process. This currently amounts to around 160,000 litres of diesel per year to generate electricity for just one submersible pump! This corresponds to an annual CO2 equivalent of 457 tonnes.

By combining a renewable energy source with a Wilo-Actun ZETOS deep-well pump, 80% savings in energy can be achieved.

In order to maximise the resource savings in the dewatering process, a holistic view of the entire process chain is necessary, from the dimensioning of a pump through its operating phase to refurbishing. Based on its close cooperation with system integrators and mine operators worldwide, Wilo can provide valuable support as a solutions provider.

Contact information

Wilo Australia Pty Ltd

Australia and New Zealand Office

2/29 Alexandra Place

Murarrie, Queensland,

4172, Australia

Tel.: +61 7 3907 6900

Web: www.wilo.com.au