Company Insight

Sponsored by HUESKER Australia

Overcoming obstacles:

Base reinforcement in infrastructure development

Standfirst...

Main image credit:

Base reinforcement involves improving the load-bearing capacity of soil and other foundational materials in construction projects. Traditionally, this process relied heavily on the use of natural materials and mechanical compaction. However, geosynthetics have introduced a new paradigm in base reinforcement through their unique properties and versatility.

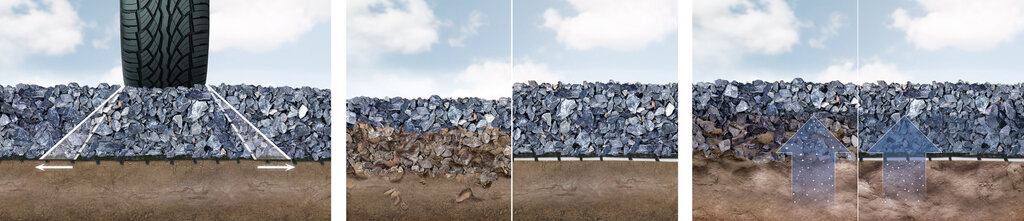

Ground stabilisation measures are needed wherever soils with inadequate bearing capacity are required to carry temporary or permanent vehicular roads. Base courses are subjected to a variety of demands due to fluctuations in the intensity of loads on soils of varying softness. Despite this, all applications serve the same purpose.

- Increased bearing capacity

- Improved trafficability

- Prevention of loss of base course material

Reinforcement, Separation, Filtration.

Enhancing load distribution

Geogrids and Geocomposites are particularly effective in base reinforcement. They improve the load distribution over a wider area, reducing the stress on underlying soils. This is particularly beneficial in road construction, where heavy traffic can lead to rapid degradation of the base layer. By integrating geosynthetics, engineers can ensure more even load distribution, resulting in longer-lasting roads and reduced maintenance costs. Application areas of Geogrids and Geocomposites include temporary roads, permanent traffic areas, working platforms, and railways.

Preventing soil erosion and stabilisation

Geosynthetics play a critical role in preventing soil erosion, which is a common issue in construction projects. By stabilising the soil, geogrids, and geocomposites help maintain the integrity of the base layer. This is especially important in areas with poor soil conditions or where slopes and embankments are involved. Using geosynthetics in these scenarios will not only enhance stability but also reduce the need for extensive earthworks.

Challenge to poor soil conditions.

Improving drainage

Proper drainage is essential for the longevity of any construction project. Geosynthetics facilitate effective drainage by allowing water to pass through while retaining the soil. This prevents waterlogging and the associated weakening of the base layer, ensuring the structure remains robust over time. In road construction, for instance, incorporating geosynthetics can prevent the formation of potholes and rutting caused by poor drainage.

Geosynthetic solutions

Geosynthetics provide a tried and tested solution for base course stabilisation. Including their high resistance to mechanical loads, they offer several key benefits, particularly in terms of cost-effectiveness and eco-efficiency.

Their responsibility is to ensure:

- Improved trafficability

- Increased bearing capacity

- Separation of base course material and subgrade

- Reduction in necessary base course thickness

- Maximisation of service life

- Reduced rutting

- Lower maintenance cost

- Bridging of inhomogeneities and evening out of the settlement

Geosynthetics perform a key function in the base course by increasing bearing capacity and improving trafficability.

Geosynthetics have revolutionised base reinforcement in civil engineering. As a result of their ability to distribute loads more evenly, prevent soil erosion, improve drainage, and offer cost-effective solutions, geosynthetics have become an indispensable part of construction.

Base reinforcement with Geocomposites.

As the industry continues to innovate, the use of these synthetic materials will expand further, resulting in advancements in infrastructure development and sustainability. Civil engineering's future lies in the continued integration and evolution of geosynthetics, promising stronger, more durable, and more environmentally friendly construction methods.

Come and visit us at the Queensland Mining & Engineering Exhibition, the largest regional mining event in Australia! Meet with our mining professionals at booth A524 and discuss your mining projects with the professionals who know the industry inside out!

Discover our base application world

Contact information

HUESKER Australia

Ms Zehra Kaya - Director Civil

Tel.: +61 730 888 000

Mobile: +61 499 024 439

Email: zehra@huesker.co

Web: huesker.com.au