AusProof has worked tirelessly over the past 29 years to provide the industry with a wide variety of safe, reliable and modern products that exceed industry needs. Couplers, plugs and receptacles available in stainless steel are Ex-certified and can be used in hazardous environments, such as underground mine sites. AusProof also manufactures high and low voltage non-Ex products in aluminium, a cost-effective and lightweight alternative ideal for non-hazardous environments such as open-cut and metalliferous mines.

While a broad range of couplers, plugs and receptacles are currently offered, AusProof continuously seeks to design new products and reinvent existing ones, to improve and expand their available products. Curious to see what goes on behind the scenes at AusProof? Watch the video below for a sneak peek!

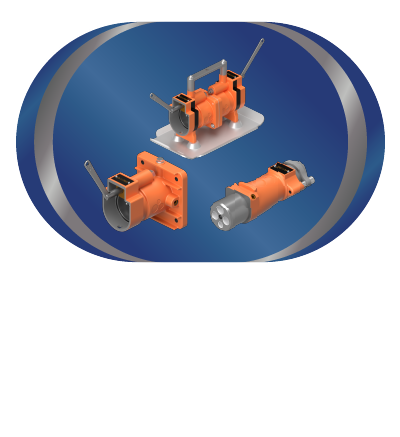

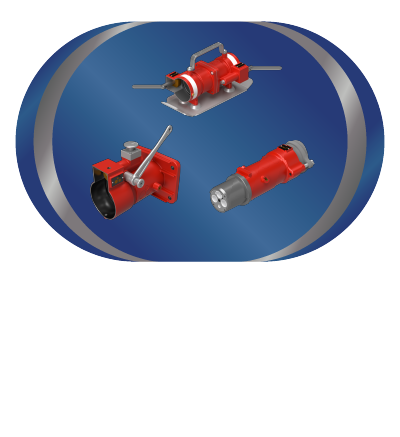

Low Voltage Stainless Steel

The Stainless Steel Low Voltage Restrained Range includes the PES, PS and PL plugs and receptacles, suitable for use in mining, tunnelling and commercial applications, including Group 1 hazardous locations. Products in this range include ratings from 60A to 425A, and from 660V to 3,300V.

After two years of work by AusProof’s Research and Development team, the PS and PL were released in 2018. The PES was released later that year, taking slightly longer in development to create an additional PES range that was rated for 60A but able to handle 90A, and be fully compatible with their 60A counterparts.

Launched alongside the PES range was AusProof’s Quick Release option, available for all stainless steel low voltage receptacles. Features of this range include single piece contacts, easy termination and flameproof repair, solid earth connectivity, and phase to earth segregation.

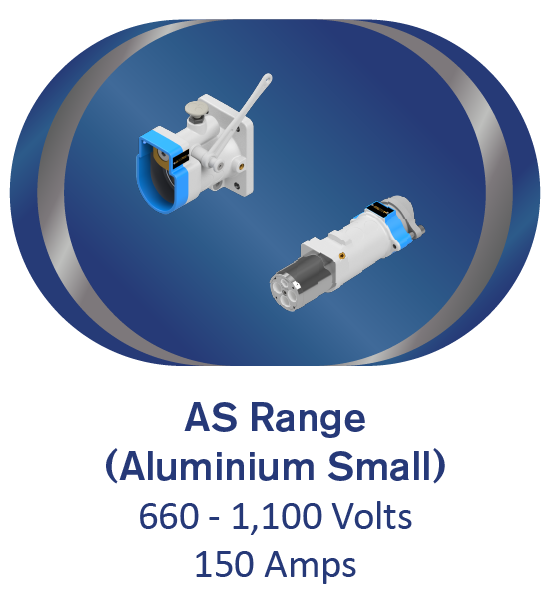

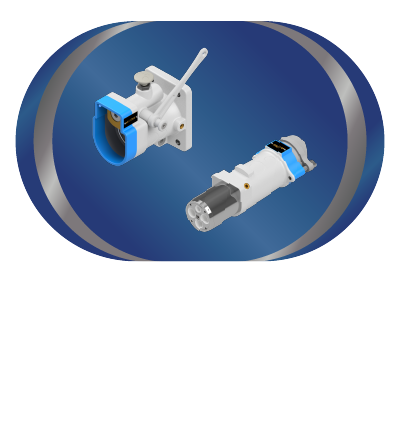

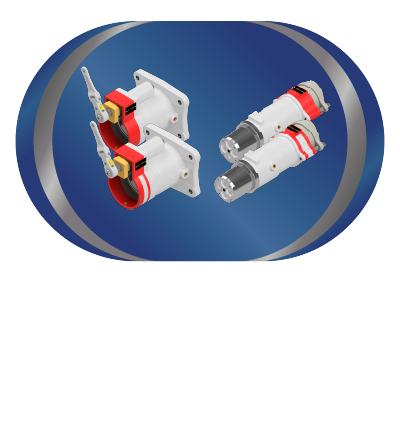

Low Voltage Aluminium

Available in the Aluminium Low Voltage Restrained Range are the AES, AS and AL plugs and receptacles, suitable for use in non-Ex operations such as metalliferous mining, open-cut mining, and pumps and tunnelling projects, with available products including ratings of 60A to 425A, and from 660V to 3,300V. Released in April 2021, this range was designed as a cost-effective and lightweight alternative for non-hazardous environment power supply solutions.

Given a fresh new look, AES, AS and AL plugs and receptacles have been painted white to easily distinguish them from AusProof’s stainless steel range, with coloured bands used to identify voltage and amp ratings. Non-Ex labels and laser marks have also been added.

All receptacles are available in Quick Release and Jack-In Release options, with the AS and AL receptacles also available in AusProof’s patented Ratchet Release option. Other features include single piece contacts, easy termination, and phase to earth segregation.

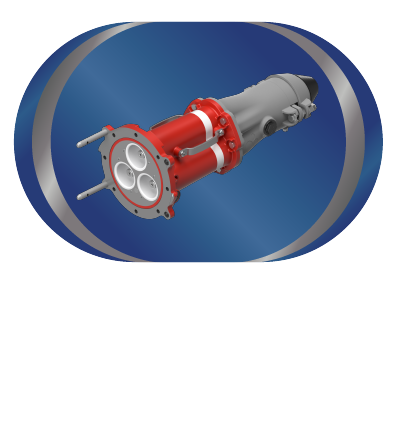

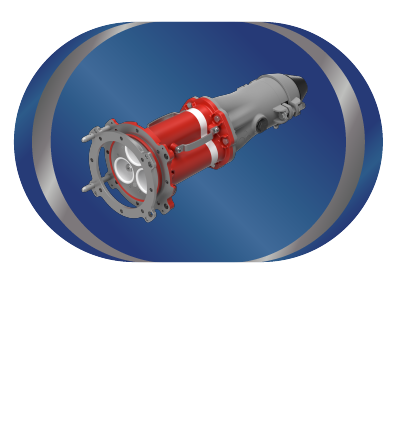

High Voltage Stainless Steel

AusProof’s High Voltage Stainless Steel Range is constantly undergoing redesign and redevelopment to improve its capabilities. These improvements and changes to the products in this range have made them the only flameproof products on the market currently capable of having their glands tensioned at any time without removing any components.

Featuring an IP66 rating, full phase to earth segregation, handles for ergonomic handling, and a genderless design, they can also be purchased with AusProof’s revolutionary LED Live Line Indicator.

Continuing the trend of redesigning and improving the Ex118BSS, in 2015 AusProof released the Ex118BSSRF. What makes the Ex118BSSRF different is its Removable Flange feature. The Removable Flange takes the guesswork out of whether or not a flameproof path is out of specification, and assists in reducing downtime and maintenance costs. Both couplers in this range have a current carrying capacity of 11,000V and are rated to 800A.

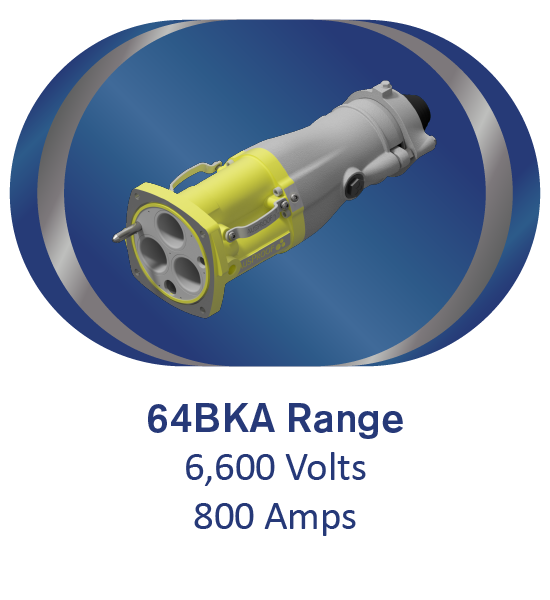

High Voltage Aluminium

Couplers in the High Voltage Aluminium Range have been ergonomically designed, are compatible with AusProof’s CAT Skid, and include handles for ease of use and OH&S support.

Seeing an opportunity to design a physically smaller coupler rated for up to 6.6kV, AusProof’s 64BKA coupler requires only four bolts to open and close the coupler system, increasing efficiency. The 114BKA, one of AusProof’s 11kV aluminium couplers, also only requires the use of 4 bolts to open and close the coupler system, with the 118BKA, AusProof’s second 11kV aluminium coupler, requiring 8 bolts.

AusProof’s flagship 22kV coupler, the 224BKA, was re-released in 1996. The original 22kV coupler design by Founding Director Philips Marks had actually been in use since 1989, the first ever to feature a genderless design and full phase segregation, with the redesign taking place when approached by a client with a specific need to be met.

Fibre Optic Range

AusProof’s Fibre Optic range is manufactured using aluminium, with a stainless steel option in development. Available in 8kV, 15kV, 25kV and 35kV, all products in this range are rated to 800A. Technology is being rapidly adapted for use in operational sites around the globe, with wireless signals used to send and receive data between a central hub and their equipment, allowing for closer monitoring.

However, with so many signals bouncing around data can be lost. The addition of fibre optic lines into the cables connecting power around a site assists in the collection of this data, with the goal of minimising data loss and confusion. AusProof’s fibre optic couplers further aid in minimising this issue, utilising expanded beam technology fitted within the couplers protective IP rating, rather than standard SC connectors, to allow the signal travelling along these lines to jump from one cable to the next.

Operators can also connect/disconnect the coupler without causing extra stress to the fibre optic lines or their signals during this process, lowering the risk of broken components, reducing downtime, and increasing reliability.

Contact Details

Our friendly team of staff are available to answer your calls, from the staff at our Gladstone head office to your local states sales representatives. If you have any questions at all, don’t hesitate to get in touch!