COMPANY INSIGHT

Sponsored by Martin Engineering

Keeping the flow is not for amateurs

S

ometimes referred to as blasters, air cannons shoot bursts of compressed air into a chute to dislodge built-up materials. The systems themselves are essentially just reservoirs of factory-compressed air attached to fast-acting discharge valves and tied to a system that controls the pattern of the bursts. Because of the higher speed of escaping air, blasters can be used to effectively keep a wide area free of buildup and carefully designed systems can effectively keep an entire chute clear.

Air cannon systems can be an effective means of preventing the buildup of materials in transfer chutes, storage vessels, and process equipment such as preheater towers and clinker coolers.

Often used with stickier materials that cannot be effectively cleared by vibrators, these materials often create less dust, limiting any concerns about added air pressure. However, for materials that will produce dust, conveyor systems should be certain to account for the added positive air pressure created by air cannons.

Customized Installation and Nozzles Position

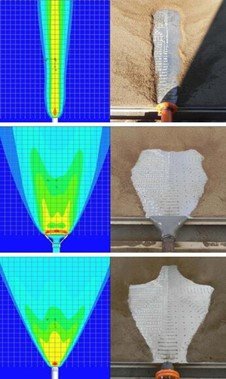

If dealing with common blockages, as shown below, the environment and material characteristics will influence exactly how we approach the installation. There are many configurations and customizable aspects of applying air cannons to an operation.

No matter the approach and configuration, air cannons are a viable solution to resolve clinging, arched, bridged, and rat-holed material. The flexibility of cannons allows you to have them fired by timers, downstream sensors, or manually when a problem is noticed.

In addition to the size of the air cannon, designers should vary the firing sequence to take into account the conditions of the chute, the materials being conveyed and the local climate.

Once an appropriate sequence is established, it can be programmed into an automated system so the system will not require attention from personnel.

The nozzles from which air is released are embedded within the chutewall, each connected either to a separate air cannon or a larger central air reservoir. These nozzles should all be positioned to direct the blast toward the outlet or direction of flow. It’s all about the location!

Subheader

Let’s talk about numbers!

The number and distribution of air cannons in a chute depends on the types of materials and the design of the chute, but in general, one air cannon can usually keep an area clear between 1.5 and 2 square meters (15 to 20 square feet).

Air cannons with an air volume of 50 liters (1.75 cubic feet) have shown good results in chute applications, but these systems come in a variety of sizes, both in terms of air reservoir and discharge diameter.

At Martin, we offer a line of air cannons that ensures you’ll find one that fits your needs, whether your application requires powerful bursts of air every few seconds to products that deliver shorter, more frequent bursts.

Our technicians and engineers are available to provide expert advice and assistance on these products and all of your bulk material handling questions and problems. Let us help!