Continued Range Expansion: AusProof’s Restrained Range

EVERYTHING ENGINEERING

AusProof’s low voltage restrained range has continued to evolve since it was first released back in 2017.

From launching entire ranges, through to re-designing existing features in the industry and the release of

brand new features — including the ratchet release receptacle.

AusProof’s research and development department has continuously explored industry trends and demands

to deliver fresh and re-invigorated products to suit customer needs within the industry.

Scroll down to learn more

AusProof’s Timeline

2017

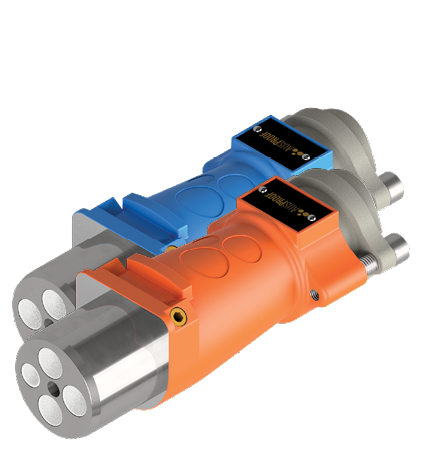

- Launch of the low voltage stainless steel restrained plug and receptacle range, from 150 amp to

2019

- The 60A/90A plug and receptacle are released.

2019

- Ergonomically designed Quick Release receptacles becomes available as an alternative to the

current jack in screw.

2020

- Additional range extensions become available for receptacles, including the back-to-back (B2B)

receptacle and receptacle gland & bracket (RGB).

2022

- Launch of the entire aluminium low voltage range, from 60A through to 425A.

2022

- First to design and manufacture the ratchet release receptacle, in addition to the currently available

jack in and quick release available.

Features

• Single piece contacts

• Easy termination

• Easy Flameproof repair

• Full solid earth connectivity throughout the product

• Phase to earth segregation

• Single solid earth body

Innovations

• Development of the first 60amp plug and receptacle with a rating of 90 amp.

• Newly designed quick release receptacle, with an ergonomic handle.

• The Receptacle Gland and Bracket (RGB) has a refreshed, sleek design with a unique two piece

design. This eliminated unnecessary flame paths, resulting in less maintenance and reduces

operational risk.

• A convenient one piece body, to assist with easy flameproof repair.

• Designed and manufactured the first ratchet release receptacle – a more efficient release system

than the quick release.

Stainless Steel Range

The stainless steel range is suitable for use in various environments in mining, tunnelling and commercial

applications, including Group 1 hazardous locations. One of the key features in the range includes an easy

to remover outer body making it easier to maintain and ensures continued reliability.

The range is fully compliant to:

• AS/NZS 1299:2009

• AS/NZS 60079.0:2012

• AS/NZS 60079.1.2015

Range Name and Descriptions

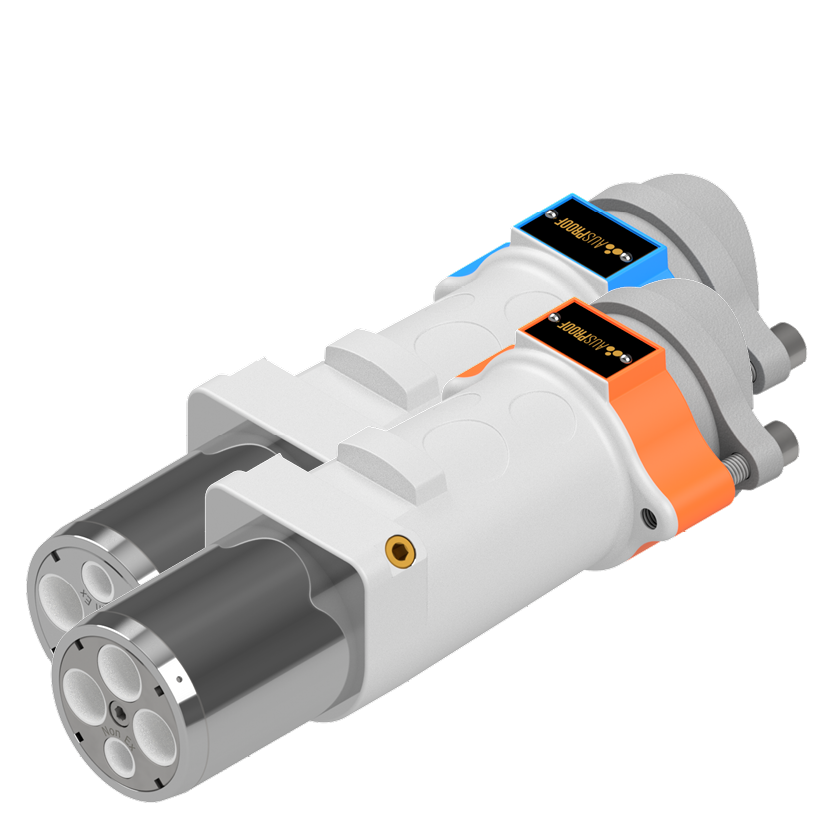

Aluminium Range

The newly designed aluminium range has been specifically for Non-Ex environments including

metalliferous and open-cut mining, pumps and tunnelling projects.

The range is a combination of both aluminium and stainless steel components, generating a number of

advantages, including:

• Overall lighter product (when compared to the Ex stainless steel range);

• Cost-effective alternative;

• Interchangeability with the existing stainless steel range for non-hazardous environments.

• Without compromising on quality, the range will still provide a high quality finished product.

The aluminium range has been tested and approved for service to the highest standard to AS/NZS 1299,

providing customers peace of mind for safety. Additionally, the heart of the product – the contacts and

insulators, are the same reputable parts that feature in the existing certified stainless steel range.

Distinguishing the aluminium range from the stainless range has been simplified with a fresh, new look,

including:

• A bold white colour;

• Using existing standard colour bands to determine the volts and amp range efficiently;

• Additional identification methods including ‘Non-Ex’ labels and laser marks on components.

FOR MORE INFORMATION Contact us