Company Insight

Sponsored by Progress Mining

Don’t settle, move forward with the mining undercarriage experts

Progress Mining is here to build on world best practices to set a new expectation in undercarriage performance, safety and running costs.

Main image credit:

In just a few short years, Progress Mining has transformed from an ambitious startup into a formidable competitor in the undercarriage market. Six years ago, a 12-month pilot project was started to generate a basic product range and test if the market was open for another aftermarket player. During this period, we found that owning the design, manufacturing, and after-sales support processes enabled us to build on our combined decades of experience and understanding of the market to come up with an offering that really got some attention. Whether it’s an emergency spare or a full undercarriage solution, Progress Mining’s high quality, precision engineered parts are a genuine, cost competitive alternative for all undercarriage needs.

It was important that we build a company that can support the basic needs of the market and be able to keep up with the continued demand. We have invested heavily in our factory, improving processes, hiring the right personnel, and spending a lot of time reviewing our systems to understand how we can deliver better. All products are designed in Australia and the engineers work closely with our European based, ISO9001 certified factory in the production process. All products are made from optimised materials using controlled heat treatment processes. Continuous quality controls are carried out throughout production to ensure the high levels of production standards are met.

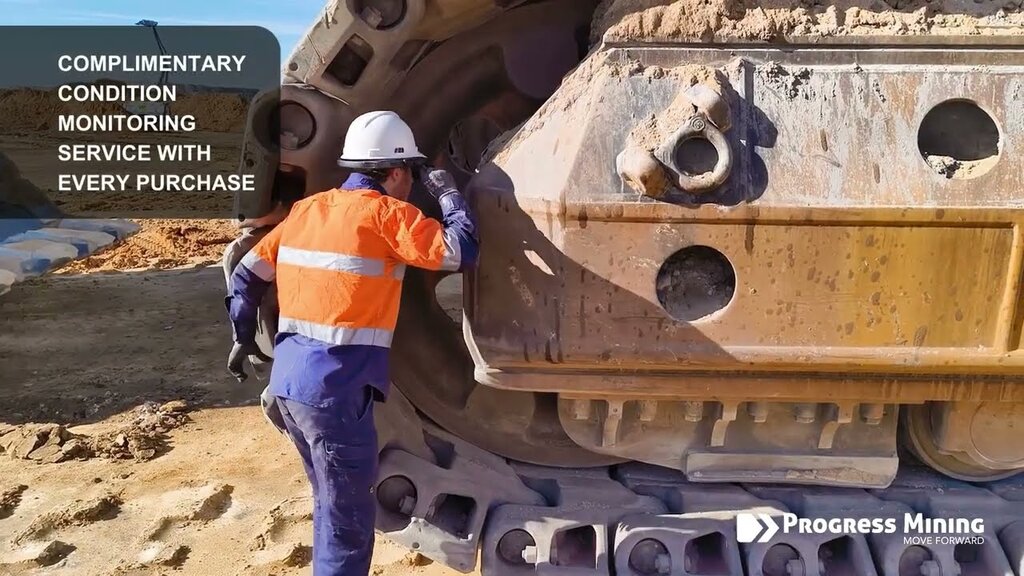

Quality design and manufacturing are only part of the Progress Mining undercarriage solution. Every purchase from Progress Mining includes our Condition Monitoring Services. The data gathered from this service allows us to support and advise our customers, helping to extend the life of their parts. Understanding our customers’ needs and working with them to provide bespoke solutions to their individual challenges allows us to provide better products and service.

Caption. Credit:

Looking to the future in terms of longer-term innovation, we see the company being a complete undercarriage supplier. That's going to include even more investment in expanding the product range, developing side frames, car bodies, slew bearings and final drives. This will give our customers the ability to purchase a walk-in walk-out solution, giving them a sole provider and support for all their undercarriage requirements. A first step in that direction is the launch of our new heavy duty link design range. This range is focused on 200 to 400 ton machines and is designed to replace the classic chain and grouser system. We are seeing customers in certain applications where these link designs are not up to heavy duty requirements. Mines that run a 500 and a 200 ton digger currently have to split undercarriage supply between two vendors. Now Progress Mining can be the one vendor on site, so that at any mine, any planner, any operator can come to Progress Mining and we can service that whole range. That range covers the EX1900s, PC2000s, R9200’s, R9250s, R9350s, and R9400s – which is a big thing for our customers because, at the moment, they don't have any alternatives available.

This link design range brings our first differentiated design. Historically we have made direct replacement products to get into the market, which has essentially hidden our abilities. We have done that intentionally to prove that we can provide the quality products that customers expect. We are now excited to show the market that we can develop our own differentiated designs that can last longer, be suitable for all applications, and are safer to use.

Caption. Credit:

Currently, particularly in the larger link designs, a 500 ton press is needed on site to split the tracks in situ. This results in additional lifting, people in awkward positions, risks of things falling, pinch points, and dealing with a lot of stored energy. We have created a master slip fit pin that can be removed without the need for the press. We see it often where someone may have a failed idler or roller, and they will not change it because of the cost, the risk, and the downtime to split the track. They are destroying the whole undercarriage because it is too difficult to split it, pushing components to the limit, having to rely on the OEM to provide the press at short notice, which is not always quick and easy. Our slip fit master pin will give more flexibility to change out those critical components rather than having to wait, helping to reduce down time and extend component life.

This innovative new design was on display for the first time at MINEXpo International 2024 in Las Vegas. If you didn’t get a chance to see it there, or just want to know more about how this innovative new product can save you time and money, contact our expert sales team today via email at info@progressmining.com or visit www.progressmining.com.

Don’t Settle, Move Forward with Progress Mining.

Contact information

Progress Mining

Tel.: +61 438 335 567

Email: info@progressmining.com

Web: www.progressmining.com