Company Insight

Sponsored by Wabtec

Wabtec Digital Mine

Mining’s most advanced collision avoidance system drives a holistic approach.

Main image credit:

Mines are complex environments with numerous interacting vehicles, particularly in congested areas like dump and loading areas. Environmental factors such as dust, rain, and fog can further complicate matters by reducing visibility. Human error, including fatigue, distraction, and miscommunication, adds another layer of complexity. Wabtec changed the game!

To alleviate these challenges, the world’s safest and most productive mines use Wabtec’s Generation 3 Collision Avoidance System (Gen 3 CAS).

Gen 3 CAS is a system that’s been designed and built from the operator’s perspective, for the operator. For mine managers and executives, the system delivers confidence in safety and production. For operators, the system delivers an unrivalled experience with advanced technology.

User feedback measures Wabtec’s Gen 3 CAS operator experience as ‘best in class’. It’s a sentiment that makes our engineering and product teams enormously proud.

A three-pronged holistic approach

The successful implementation of a collision avoidance system requires mine managers and operators to first & foremost address 3 key factors. They are straightforward:

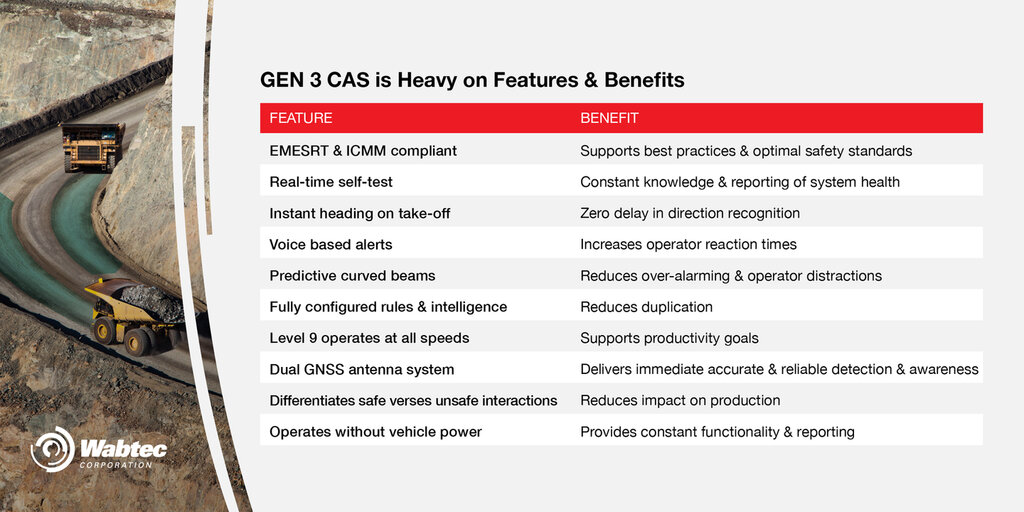

- Advanced Technology: Wabtec’s Gen 3 CAS offers features like voice-based alerts, instant heading on take-off, curved beams, and accurate positioning to minimize nuisance alarms. Real-time system health checks, diagnostics, and fault reporting ensure system reliability and enables proactive maintenance.

- Robust Operational Practices: Implementing mining best practices, change management methodologies, comprehensive training programs, and regular maintenance plans are crucial for creating a safety-conscious culture and ensuring the long-term effectiveness of CAS.

- Human-Factors Engineering: Designing systems with the operator in mind is essential for acceptance and trust. Intuitive user interfaces with clear, context-specific alerts, including voice instructions and simple graphics, enable operators to respond effectively to potential collision threats.

Caption:

Data and analytics for continuous improvement

Data and analytics are essential for optimising operations. Good analytics can also increase the effectiveness of Gen 3 CAS through the identification of areas for improvement. By analysing data from CAS, mines can identify risky operator behaviour, anticipate potential hazards, and make data-driven decisions to enhance safety and productivity.

The cost of safety and inaction

Implementing a Gen 3 CAS requires a significant upfront investment, but the long-term benefits far outweigh the costs. CAS can mitigate expenses related to safety violations, injuries, work stoppages, administrative time, training costs for replacement workers, lost productivity, insurance premiums, and equipment damage. A strong safety record enhances a company's reputation and contributes to a more productive work environment.

Considerations for CAS selection & implementation

Several critical considerations should guide the selection and implementation of CAS to ensure alignment with industry best practices.

- Access the Maturity of Baseline Controls: Understanding EMESRT Levels 1-6 controls is essential, as inadequate baseline controls can render the technology less effective or even introduce additional risks.

- Alignment with Best Practice & Integration with Existing Controls: Ensure the system can provide awareness, advisory, and intervention capabilities (Levels 7-9). The system should not function as a standalone solution.

- The installation process must follow a structured project approach: Thorough scoping exercises, stakeholder engagement, change management, and training programs for both operators and maintenance crews are critical success factors.

- Long-Term Maintenance and Scalability of the System: The mine site needs to ensure the system can adapt to changing operational needs. By addressing these considerations, mining operations can achieve safer and more efficient vehicle interactions, ultimately contributing to their zero-harm objectives.

White Paper recommendation

A ‘must read’ for any mining organisation considering the deployment of CAS technology is the impartial White Paper: Key Insights for the Successful Implementation of Proximity Detection & Collison Avoidance Technology for Reducing Vehicle Interaction Risk.

The role of Artificial Intelligence

AI Smart Cameras are playing an increasingly important role in enhancing situational awareness, particularly in edge and void detection, fatigue monitoring, and object recognition.

They offer a reduced time in deployment compared to most CAS systems. Combined that with good interoperability, configuration and open API’s, AI Smart Camera systems enable an accelerated ROI.

As a CAS solution for mining, AI Smart Cameras have limitations and compromises. For example, they can’t deliver advanced features such as curved beams or advisory for priority rules for a T-intersection. As the technology is still maturing there is also a tendency for these companies to have a smaller set of service offerings, so like most products and services in the technology space, there are trade-offs.

Conclusion

It’s important to note that while technology is a critical component of collision avoidance, it is not a ‘silver bullet.’ Successful implementation requires a holistic approach that integrates technology with people, processes, and existing controls. Continuous monitoring, maintenance, and optimisation are also essential to ensure long-term effectiveness and operator trust in these systems.

Contact information

Wabtec Digital Mine

Eagle Farm

Brisbane, Australia

Tel.: +61 7 3177 4226

Email: apac.dmt@wabtec.com

Web: www.wabteccorp.com