200 Fairview Road, Unit #2

Barrie, Ontario

Canada, L4N 8X8

Phone: +1 705-792-9968

Web: tnrdoors.com

Email: info@tnrdoors.com

Benefits of a TNR Custom Built Rubber Door System

Patented Curtain Retention System

Withstands accidental vehicle impacts

Withstands wind and negative building pressures

Easily and quickly reset after an impact with basic tools and standard fasteners

Rugged Drive Systems

Dependable operation, long life

Programmable and customizable for access & safety

Explosion proof options

Rugged Drive Systems

Dependable operation, long life

Programmable and customizable for access & safety

Explosion proof options

Lifetime Warranty

Proven performance, superb reliability

Peace of mind for Maintenance & Operations Managers

Headframe - high cycle service doors, reliability is critical for continuous operation

Ore Load-out - rugged, dirty location, high risk of vehicle impact

Mill - high cycle service / maintenance doors

Concentrate Storage - very dirty, corrosive, abrasive environment

Smelter - large openings with negative pressure, dirty, abrasive

Refinery - service doors, anode delivery

Service Buildings & Truck Shops - extra-large openings for trucks, loaders, trains

Ore Thaw Sheds - Dirty, high cycle, varying temperatures

Ideal Rubber Door Applications in Mining

Heavy Duty Rubber Door Systems for Challenging Environments

Rubber Curtain Material Limited Lifetime Warranty

NEWGEN® Guide and Curtain Lok™ System Limited Lifetime Warranty

Knock-away Bottom Bar & Loop Seal

Self-Supporting Frame

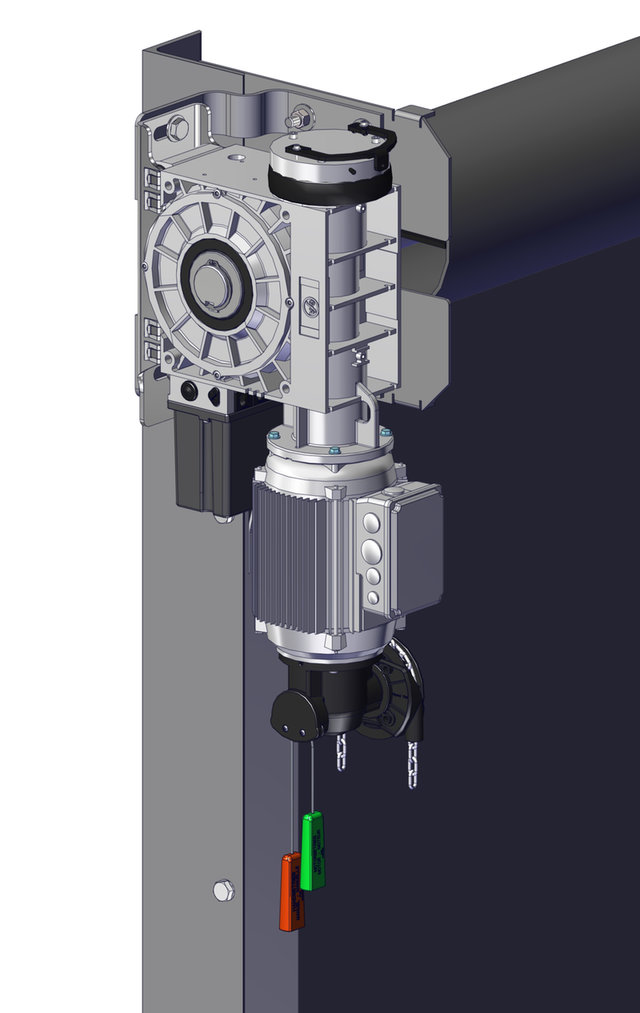

Direct Drive or Chain Drive System

Benefits of a TNR Custom Built Rubber Door System

Patented Curtain Retention System

Withstands accidental vehicle impacts

Withstands wind and negative building pressures

Easily and quickly reset after an impact with basic tools and standard fasteners

Rugged Drive Systems

Dependable operation, long life

Programmable and customizable for access & safety

Explosion proof options

Rugged Drive Systems

Dependable operation, long life

Programmable and customizable for access & safety

Explosion proof options

Lifetime Warranty

Proven performance, superb reliability

Peace of mind for Maintenance & Operations Managers

Ideal Rubber Door Applications in Mining

Headframe - high cycle service doors, reliability is critical for continuous operation

Ore Load-out - rugged, dirty location, high risk of vehicle impact

Mill - high cycle service / maintenance doors

Concentrate Storage - very dirty, corrosive, abrasive environment

Smelter - large openings with negative pressure, dirty, abrasive

Refinery - service doors, anode delivery

Service Buildings & Truck Shops - extra-large openings for trucks, loaders, trains

Ore Thaw Sheds - Dirty, high cycle, varying temperatures

Heavy Duty Rubber Door Systems for Challenging Environments

Rubber Curtain Material Limited Lifetime Warranty

NEWGEN® Guide and Curtain Lok™ System Limited Lifetime Warranty

Knock-away Bottom Bar & Loop Seal

Self-Supporting Frame

Direct Drive or Chain Drive System

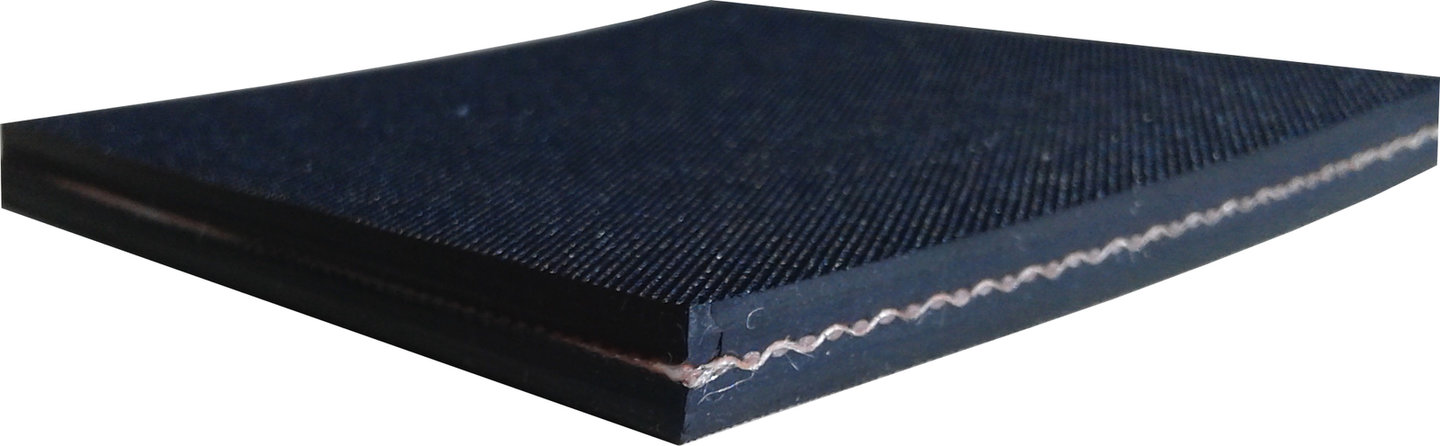

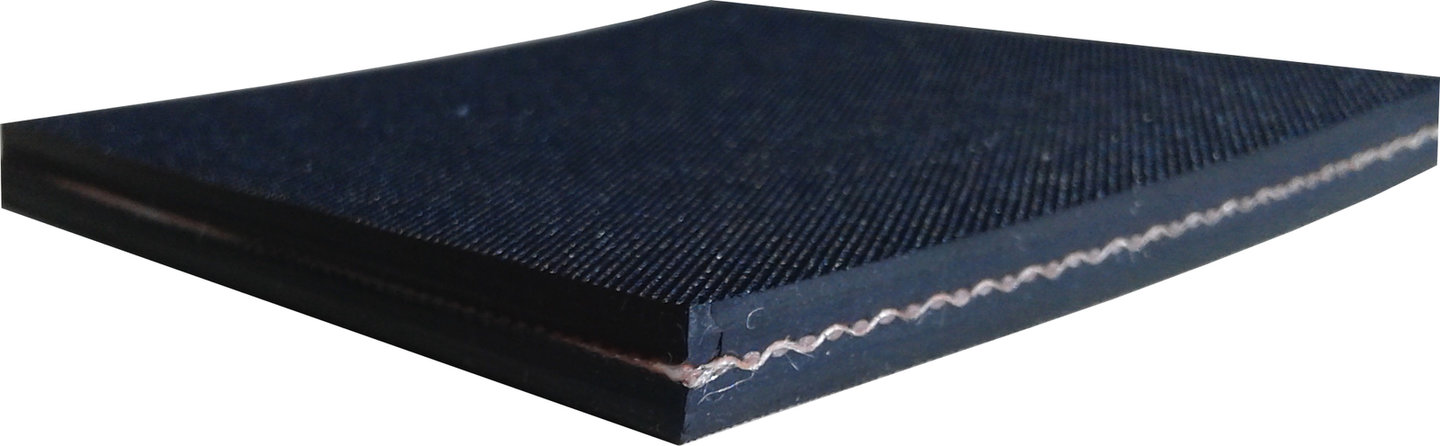

Rubber Curtain Material Limited Lifetime Warranty

¼” thick Styrene-Butadiene Rubber (SBR) with

polyester core weave reinforcement

- Standard Black

- Optional Grey, Blue, EPDM rubber

Extremely durable, flexible and resistant to harsh environments and impacts in temperatures from -40°F to 180°F

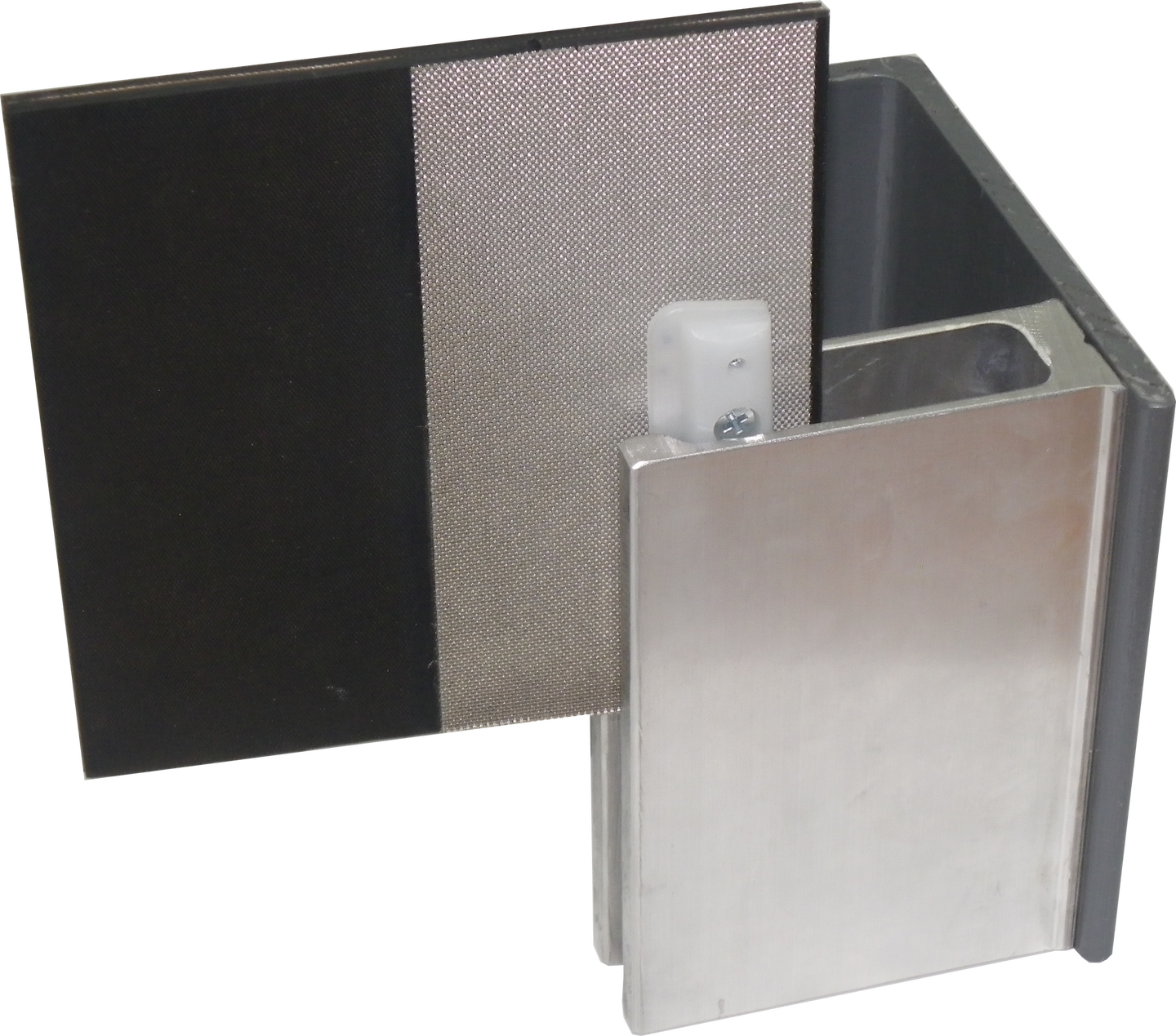

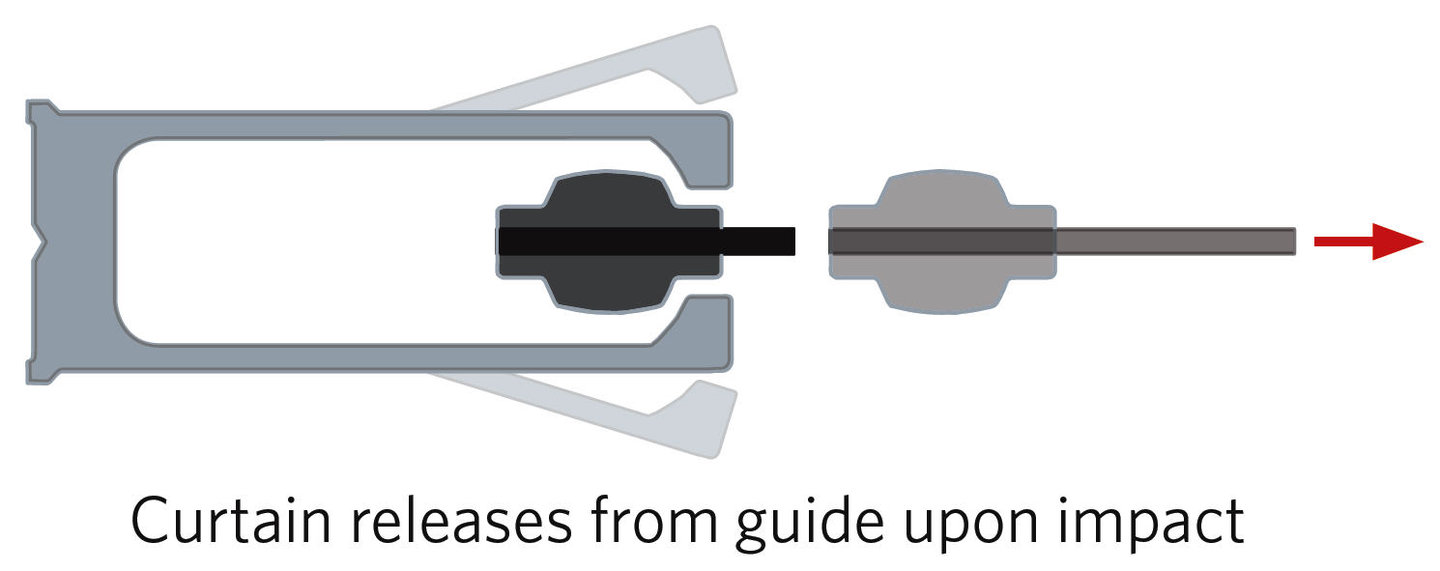

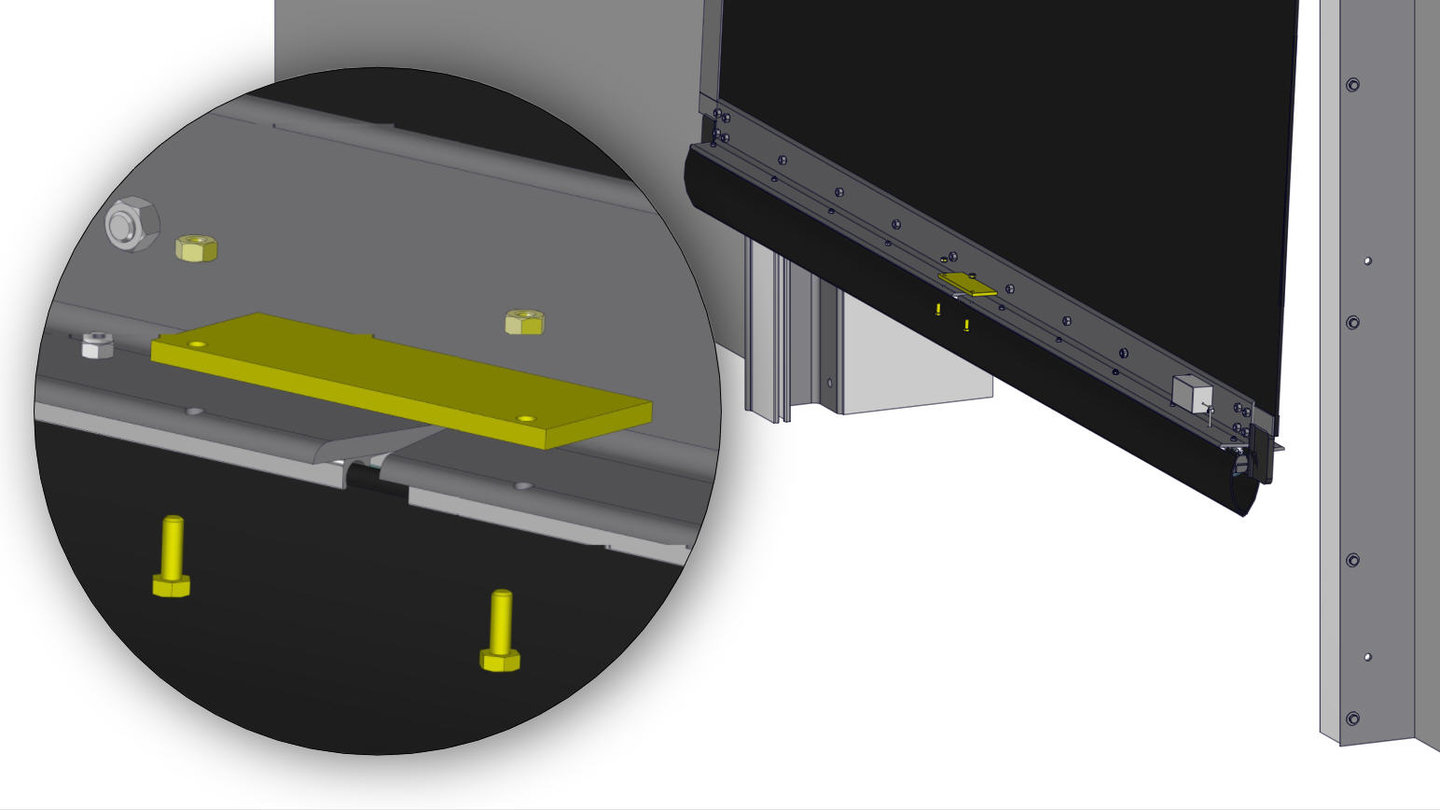

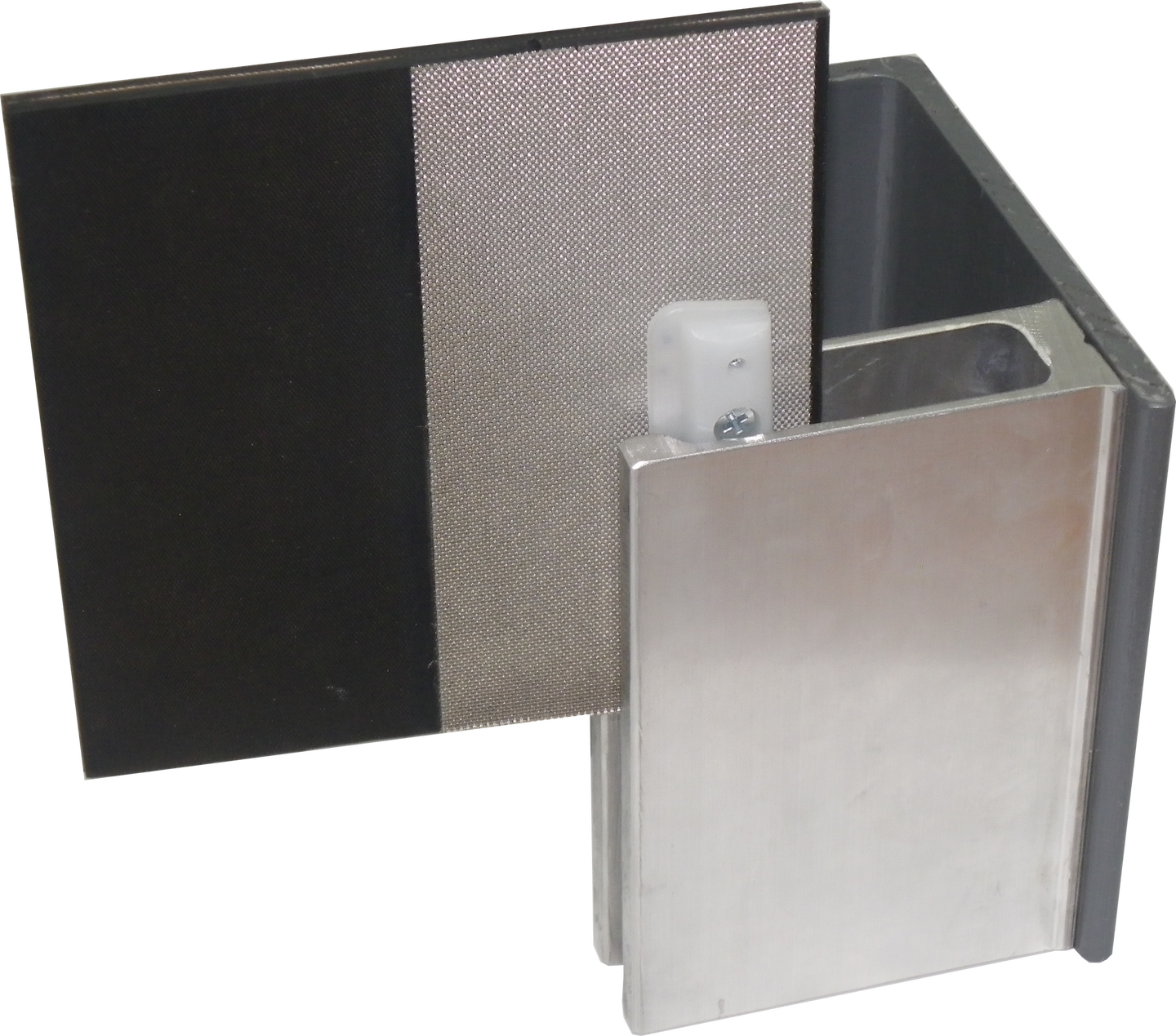

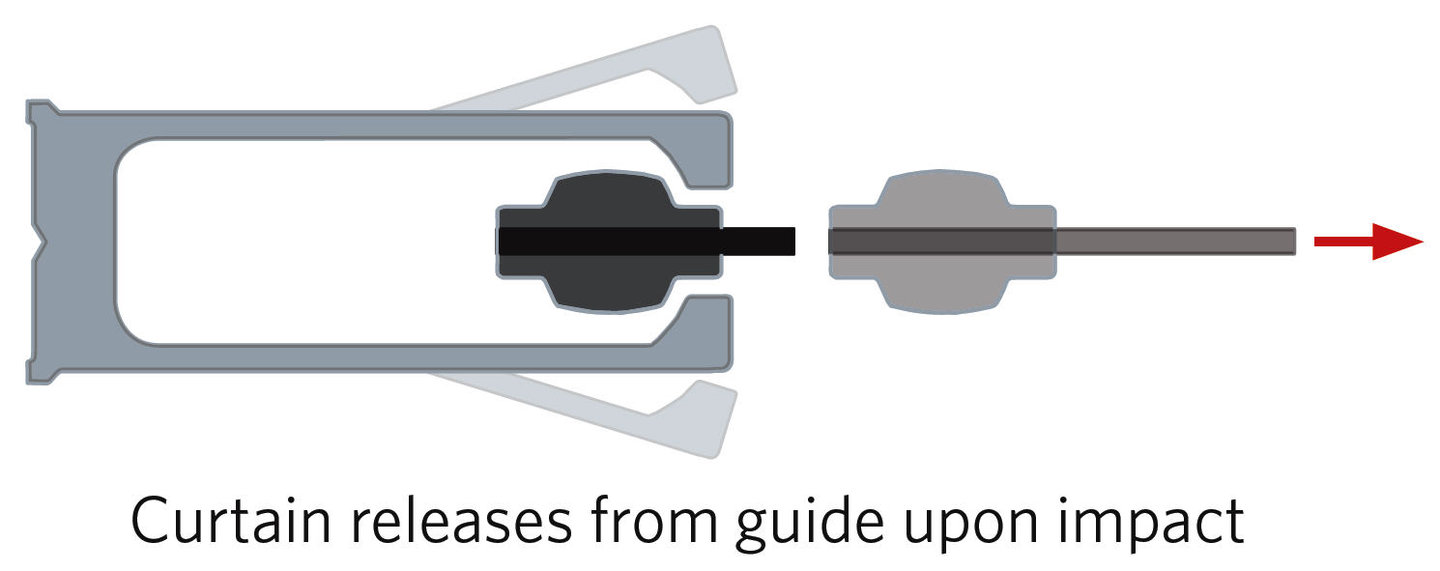

NEWGEN® Guide and Curtain Lok™ System Limited Lifetime Warranty

- Patented curtain retention system that releases upon impact

- Rated for Wind Class 5 (42 psf)

Reliable and consistent door operation, withstand repeated

impacts, quick to repair and reset, no guide gap maintenance

required.

Self-Supporting Frame

Steel mounting angles, pre-drilled and painted.

Allows for quick and easy installation of door system.

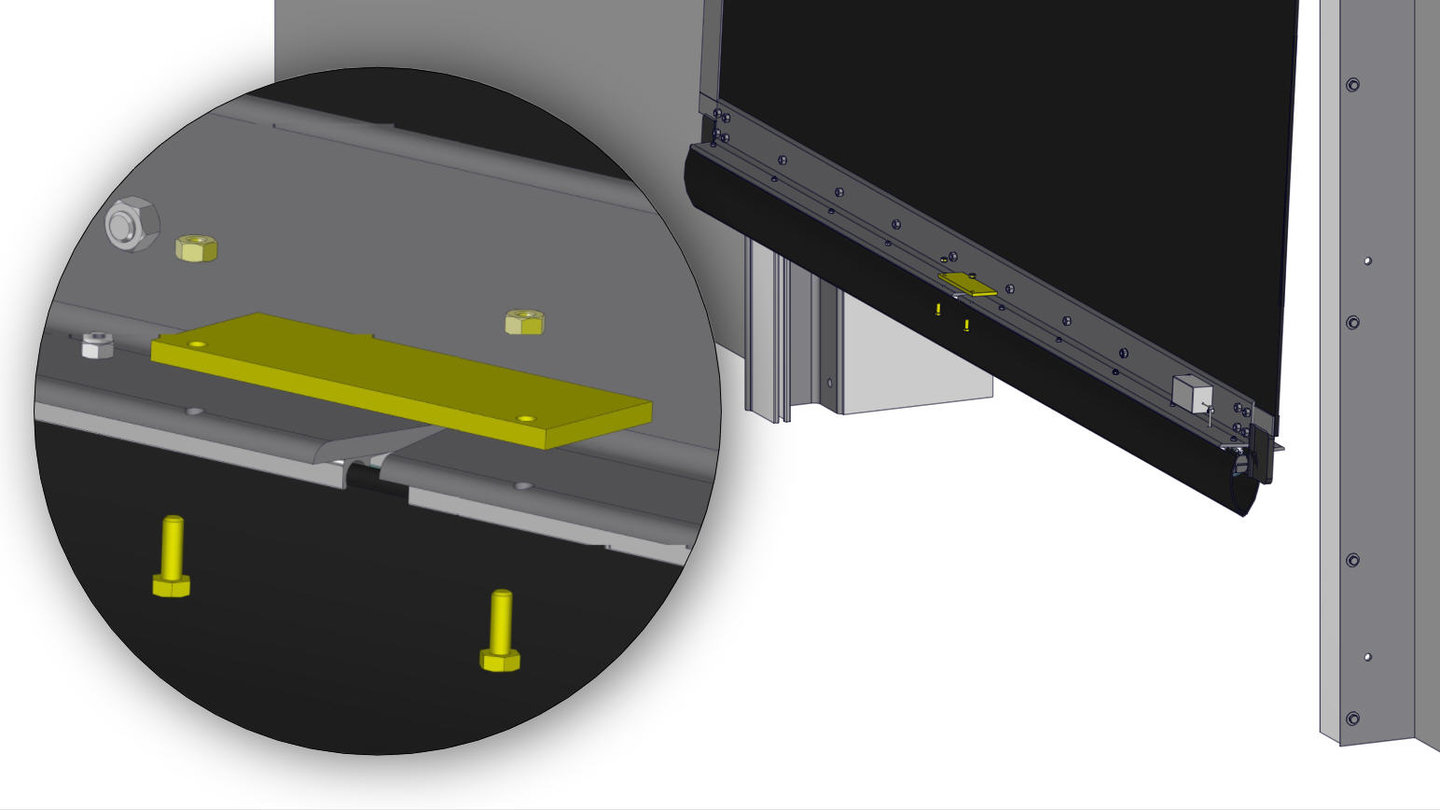

Knock-away Bottom Bar & Loop Seal

- Patented aluminum bottom bar design with pivoting

knock-away arms that release from guides upon impact

- durable and flexible EPDM rubber loop

- After impact door is easily and quickly reset

- Minimizes cost and downtime

- Large rubber loop seals to uneven floors

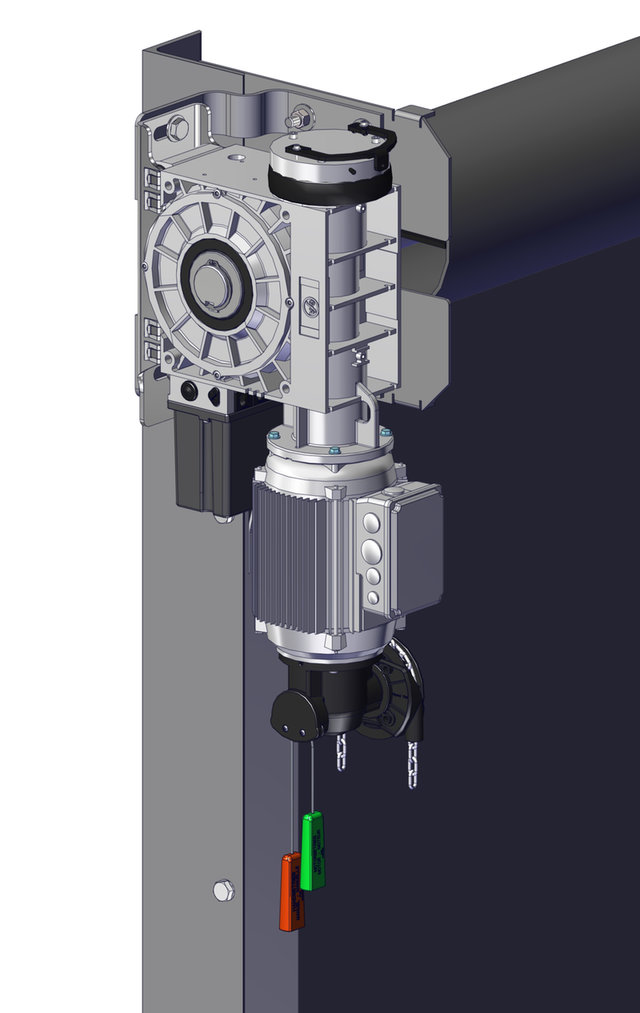

Direct Drive or Chain Drive System

- Rugged electric operator designed for high performance door system

- Reliable, maintenance free safety brake

- Smooth, quiet operation with

soft-start/soft-stop