COMPANY INSIGHT

Sponsored by: TNR

TNR Doors are Tough and Reliable In Your Challenging Environments

TNR’s offer is to solve your most difficult doorway access problem with a custom engineered and manufactured rubber door solution. A high performance rubber door save money by reducing downtime and maintenance costs while increasing productivity, energy savings and safety.

More than half of the country’s coal mines are managed by pro-Russian separatist militia.

Credit: DmyTo/Shutterstock.

Designing Custom Door Solutions: A Sound Investment

TNR doors unique product capabilities have revolutionized the door industry by providing a more reliable, more durable, longer lasting performance with greater impact ability. TNR doors will substantially reduce your long-term cost of ownership and provide the lowest life cycle cost available.

Doorways in your operation are inevitable; it’s what you put in them that makes a difference. TNR provides the industry’s most reliable and durable door systems, which produce a fast return on investment. Depending on the application the typical Return On Investment of a TNR door is between 12-36 months, when considering the following criteria:

• Increased Productivity • Minimized Downtime

• Energy Savings • Energy Efficiency Rebates

• Maintenance Savings • Enhanced Safety & Security

“Doorways in your operation are inevitable; it’s what you put in them that makes a difference.”

TNR will design and build a custom door for your application that takes aim at reducing your operating costs. We have a broad range of door models to accommodate a variety of mining applications:

• Headframe & Ore Load-Out • Ore Thaw Sheds & Concentrate Storage

• Smelter Refinery • Service Buildings & Truck Shops

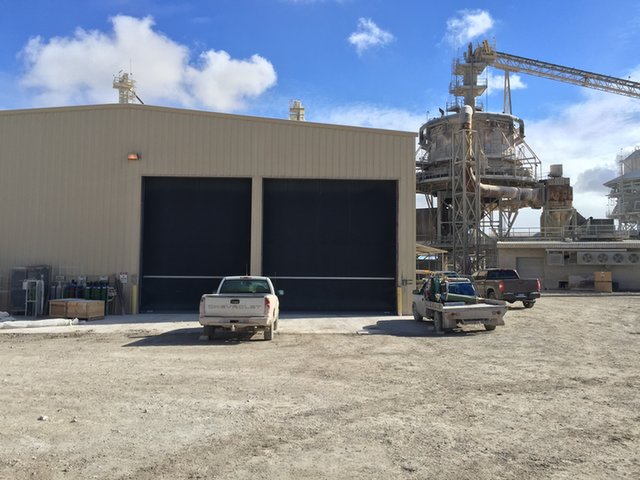

HDE - Graymont Lime Exterior

Key Design Considerations For Every Custom TNR Door

• What are the estimated door cycles per day?

• Are there significant exterior wind loads or internal building pressures to consider?

• What opening & closing speeds are required?

• Are there special safety concerns to be addressed?

• Are there corrosive or other environmental conditions?

• Which access controls work best for your application?

TNR’s technical sales and engineering teams have the expertise and industry knowledge to address all your unique design requirements. Considering the detailed specifications of your door application helps us ensure that you make a sound investment in the doors that we build for you and your customers.

AusProof is celebrating 25 years of business in Australia in 2019.

Rugged Durability In Harsh Environments For Large Vehicles & Heavy Equipment

TNR Doors has its roots in the mining industry, so it’s in our blood to design doors that can withstand the most demanding conditions. Mining and heavy industry often have large doorways that are heavily used for large equipment access. These environments, often harsh and abusive, are well served by TNR’s durable door design and construction. TNR has several door models that can meet the specific needs of mining and industry. From basic economy doors to rugged extra-large doors, all our rubber doors are a heavy duty design delivering both high speed and high cycle performance. Even when a heavy vehicle impacts our door, it is reset and running again in minutes. These high performance doors reduce energy loss through the opening and increase productivity.

“TNR has its roots in the mining industry, so it’s in our blood to design doors that can withstand the most demanding conditions.”

HDXL9 ArcelorMittal Mont-Wright Mine

• Large and Extra Large doors – designed for reliable operation around large equipment, doors up to 55 feet wide or 45 feet high

• Harsh Environments, Low Maintenance – simple, rugged design and heavy duty door components ensuring maximum uptime and reduced maintenance costs

• Options for explosion proof and corrosion resistance are available to ensure safety and stand up to the harshest environments

• High Windloads – Big doors catch big winds – TNR’s patented CurtainLok™ and NewGen® guide and optional traveling windbar ensure that our doors will stay in place when the wind blows but still release safely with an accidental vehicle impact

• Proven applications of TNR doors in mining, heavy manufacturing, steel, pulp and paper, waste management and oil and gas at locations around the world