CRITICAL MINERALS

Critical lack of critical minerals

According to an IEA report, supplies of critical minerals will need to pick up sharply over the coming decades as they are crucial components for the manufacturing of renewable energy technologies. Yoana Cholteeva looks into the specifics of this vicious circle and the measures that can be taken to rectify it.

D

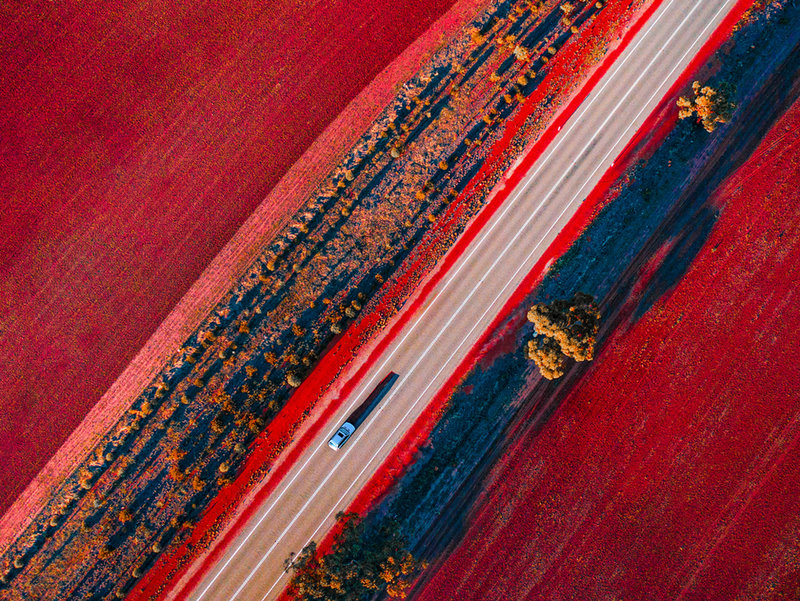

emand for critical minerals is set to soar as more and more countries are pursuing the net-zero goals set out in the Paris Agreement. As the processing of many minerals essential for the renewable transition is highly concentrated in a handful of countries, including Australia, the Democratic Republic of the Congo, Indonesia, and China, this could ultimately make the prospects of swift and efficient transition harder than expected.

The recently published IEA report, ‘The Role of Critical Minerals in Clean Energy Transitions’, has emphasised the importance of the minerals’ supply to key clean energy technologies such as electric vehicles and wind turbines. The report concludes that critical minerals need to pick up sharply over the coming decades to avoid potential energy security hazards.

The missing piece of the puzzle

As part of its report, the IEA has shed a light on the fact that the mineral requirements of an energy system powered by clean energy technologies would be more demanding than one that runs on fossil fuels.

For example, a typical electric car requires six times the mineral inputs of a conventional car, and an onshore wind plant requires nine times more mineral resources than a similarly sized gas-fired power plant.

“Left unaddressed, these potential vulnerabilities could make global progress towards a clean energy future slower and more costly – and therefore hamper international efforts to tackle climate change,” says Dr Fatih Birol, executive director of the IEA as part of a statement.

“This is what energy security looks like in the 21st century, and the IEA is fully committed to helping governments ensure that these hazards don’t derail the global drive to accelerate energy transitions.”

Findings from the IEA report have generally indicated that the current global supply and investment plans are not sufficient to support the accelerated transition needed to meet the Paris Agreement goals.

Left unaddressed, these potential vulnerabilities could make global progress towards a clean energy future slower and more costly.

The report has also suggested that a concerted effort to reach those goals would have to involve the quadrupling of mineral requirements for clean energy technologies by 2040. In addition, an even faster global transition to net zero by 2050 would require six times more mineral inputs in 2040 than today.

In response, the IEA has recommended a few key areas of action so that policymakers can ensure that critical minerals enable an accelerated transition to clean energy rather than becoming a bottleneck.

Some of these recommendations include the fostering of stable supplies of critical minerals to support accelerated clean energy transitions; the importance of governments to lay out their long-term commitments for emission reductions; the promotion of technological advances; the scaling up of recycling to relieve pressure on primary supplies; the maintaining of high environmental and social standards, and the strengthening of international collaboration between producers and consumers.

The outlook for copper

Unlike oil, which is produced in various locations around the world, the production of critical minerals is associated with complex supply chains and comes with an increased risk of physical disruptions, trade restrictions, and other developments in major producing countries.

A good example is copper, which is sought after in large quantities due to its use in electrical equipment such as wiring, motors, and industrial machinery.

While there is no shortage of the commodity itself, the quality of available deposits is declining as producers are subject to stricter environmental and social standards. Provoked by these factors, copper prices hit their highest level in a decade in April this year, rising by about 21%.

While companies are realising the opportunity to tap into the copper market and trying to get involved with new mining deposits, the opening of mines takes a long time, so other strategies such as copper recycling are also being considered.

Around 50% of the copper used in Europe now comes from recycling.

Michèle Brülhart, executive director of the Copper Mark, an assurance framework company, explains: “Copper recycling can require significantly less energy than mining and represents another important means through which the copper industry can address the challenge of decarbonisation.

“The Copper Mark has identified positive trends around the increased recycling of copper. Around 50% of the copper used in Europe now comes from recycling and globally, copper recycling now saves up to 40 million tonnes of CO₂ annually.”

Despite these efforts, it is important to note that recycling processes are not carbon neutral and are not sufficient by themselves to address growing demand, and it is important to emphasise innovation at the mining, smelting, refining, and fabricator levels of the supply chain to promote responsible methods of copper production and manufacturing.

As copper will continue to be a critical material for almost all clean energy technologies, its demand is expected to increase significantly over the coming years. At the same time, Brülhart is confident that there is enough copper, based on recycled and mined material, to support the green transition.

“According to USGS data, since 1950 there has been, on average, 40 years of copper reserves and over 200 years of resources left, which include reserves and both discovered and undiscovered deposits,” he says.

Opportunities and outlook for critical minerals

In scenarios concerning the need to take action to prevent further climate change and its consequences, the rise of low-carbon power generation to meet climate goals would mean that mineral demand from this sector will triple by 2040, with the material-intensive offshore wind sector being projected to top the rankings.

This sector is then followed by solar PV, which will also have a big hunger for critical minerals. The expansion of electricity networks in turn will also require substantial amounts of copper and aluminium.

“[These] challenges are not insurmountable, but governments must give clear signals about how they plan to turn their climate pledges into action. By acting now and acting together, they can significantly reduce the risks of price volatility and supply disruptions,” Birol says.

While Australia is already the world's top producer of hard rock lithium concentrate and the second-largest producer of zircon and rare earth elements, the Australian Government is looking to capitalise on its strengths and recently established the Critical Minerals Facilitation Office, with a mandate of continuing to drive further critical minerals investment in existing and new mines in Australia.

Governments must give clear signals about how they plan to turn their climate pledges into action.

As there is a huge growth opportunity for countries rich in natural resources with existing infrastructure, and a stable regulatory framework for the sustainable sourcing of critical minerals, other countries looking to tap into critical mineral deposits need to consider the environmental repercussions that such operations can bring.

When it comes to the copper industry for example, while it has a fundamental role to play in accelerating the green transition “it is important that its production does not cause harm to people and the environment”, Brülhart says.

Beyond the challenge to decarbonise the mineral extraction processes and supply chain, for many operators across the world, becoming part of the solution to insufficient critical minerals would involve considering broader environmental and social issues – including water usage and pollution from tailings.

Along with these, increased need for further investment in the promotion of responsible production strategies to prevent, mitigate, and remedy negative environmental and social externalities should be expected.